Environmentally-friendly tile binder, and preparation method and use method thereof

A tile adhesive, an environmentally friendly technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., to achieve the effect of improving compatibility, high heat resistance, and ultra-high weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of environmental protection ceramic tile adhesive, is made up of the raw material of following percentage by weight:

[0024]

[0025] The sum of the weight percentages of the above components is 100%.

[0026] The silicone emulsion is silicone-modified acrylic acid.

[0027] The polymer resin is an oxygen-containing or oxygen-linked polymer such as an acrylic resin.

[0028] The silane coupling agent is isobutyltriethoxysilane coupling agent.

[0029] The antifungal agent is 2-methyl-4-isothiazolin-3-one.

[0030] The wetting agent is polyoxyethylene fatty alcohol ether.

[0031] The antifreeze agent is 1,2-propanediol.

[0032] The defoamer is a polyether siloxane copolymer emulsion containing fumed silicon dioxide.

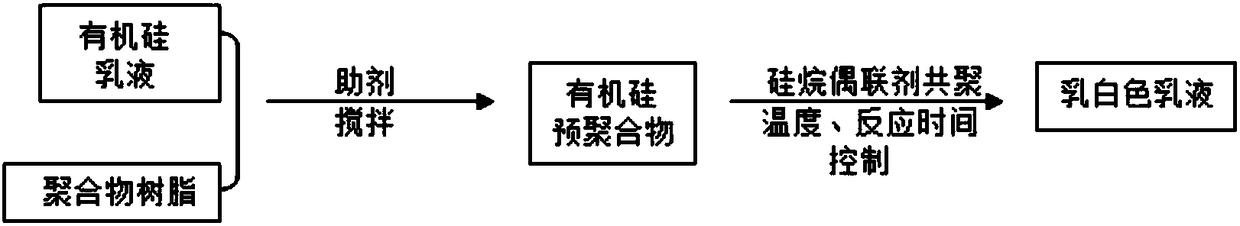

[0033] A preparation method of an environmentally friendly ceramic tile adhesive, comprising the following preparation steps: firstly adding the silicone emulsion and the polymer resin according to the weight percentage to the mold inhibit...

Embodiment 2

[0035] Embodiment 2: This embodiment is an example with the preparation of 1000 kilograms of ceramic tile adhesives:

[0036] 700 kg of water-based silicone emulsion and 260 kg of polymer resin, after adding 1.5 kg of antifungal agent, 2.5 kg of wetting agent, 13.5 kg of antifreeze agent, 2.5 kg of defoamer, fully mixed and stirred to form a silicone prepolymer ; Then first react 20 kg of silane coupling agent at 69°C for 2.5 hours to obtain a hydrolyzate; then add the hydrolyzate of the silane coupling agent to the organosilicon prepolymer prepolymer system and fully stir for modified copolymerization React for 2.5 hours to produce a milky white emulsion. Brush or roller coat the obtained milky white emulsion on the inorganic silicate interface to be pasted with tiles to form an adhesive layer. Then paste the tiles and compact to complete the pasting process of the tiles.

[0037] The cohesive strength performance detection report result of the adhesive that embodiment 2 make...

Embodiment 3

[0040] Embodiment 3: This embodiment is an example with preparing 1000 kilograms of ceramic tile adhesives:

[0041] 759 kg of water-based silicone emulsion and 200 kg of polymer resin, after adding 2 kg of antifungal agent, 2 kg of wetting agent, 10 kg of antifreeze agent, 2 kg of defoamer, fully mixed and stirred to form a silicone prepolymer ; Then first react 25 kg of silane coupling agent at 73°C for 2 hours to obtain a hydrolyzate; then add the hydrolyzate of the silane coupling agent to the organosilicon prepolymer prepolymer system and stir thoroughly to undergo modified copolymerization React for 2 hours to form a milky white emulsion. Brush or roller coat the obtained milky white emulsion on the inorganic silicate interface to be pasted with tiles to form a bonding layer, then paste the tiles and compact to complete the pasting process of the tiles.

[0042] The cohesive strength performance detection report result of the adhesive that embodiment 3 makes is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com