High-performance hard PVC foamed plastic and preparation method thereof

A foam plastic and high-performance technology, which is applied in the field of preparation of high-performance rigid PVC foam plastic, can solve the problems of limiting the application range of PVC foam plastic, poor thermal deformation resistance and thermal stability, and poor impact resistance. Achieve the effect of low oil absorption, easy access and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

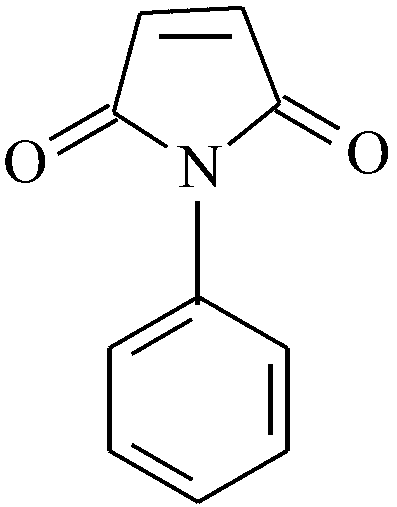

[0024] A kind of high-performance rigid PVC foam plastics, its raw material composition and mass parts are respectively: polyvinyl chloride 100 parts (EPVC:SPVC=3:1); Stearate 10 parts; Foaming agent 23 parts; Activated calcium carbonate 5 parts; PhMI-MMA-AN terpolymer polymer heat-resistant modifier 5 parts. in,

[0025] The percentage by weight of the PhMI-MMA-AN terpolymer polymer heat-resistant modifier is: 25% of N-phenylmaleimide; 55% of methyl methacrylate; 20% of acrylonitrile; water-soluble Initiator 1.5%; Emulsifier 2.5%.

Embodiment 2

[0027] A kind of high-performance rigid PVC foam plastics, its raw material composition and mass parts are respectively: polyvinyl chloride 100 parts (EPVC:SPVC=3:1); Stearate 10 parts; Foaming agent 23 parts; Activated calcium carbonate 5 parts; PhMI-MMA-AN terpolymer polymer heat-resistant modifier 15 parts. in,

[0028] The percentage by weight of the PhMI-MMA-AN terpolymer polymer heat-resistant modifier is: 20% of N-phenylmaleimide; 60% of methyl methacrylate; 20% of acrylonitrile; water-soluble Initiator 2%; Emulsifier 2.5%.

[0029] The preparation steps are as follows:

[0030] Step 1: Put 100 parts of polyvinyl chloride, 10 parts of stearate, 23 parts of foaming agent, 5 parts of activated calcium carbonate and 15 parts of PhMI-MMA-AN terpolymer polymer heat-resistant modifier into the mixing in a container;

[0031] Step 2: Use a high-speed shearing dispersing emulsifier to disperse the mixture for 5 minutes to 8 minutes;

[0032] Step 3: Preheat the mold to 120...

Embodiment 3

[0037] A kind of high-performance rigid PVC foam plastics, its raw material composition and mass parts are respectively: polyvinyl chloride 100 parts (EPVC:SPVC=3:1); Stearate 10 parts; Foaming agent 23 parts; Activated calcium carbonate 5 parts; PhMI-MMA-AN terpolymer polymer heat-resistant modifier 20 parts. in,

[0038] The percentage by weight of the PhMI-MMA-AN terpolymer polymer heat-resistant modifier is: 25% of N-phenylmaleimide; 55% of methyl methacrylate; 20% of acrylonitrile; water-soluble Initiator 1.5%; Emulsifier 2.5%.

[0039] The preparation steps are as follows:

[0040] Step 1: Put 100 parts of polyvinyl chloride, 10 parts of stearate, 23 parts of foaming agent, 5 parts of activated calcium carbonate and 20 parts of PhMI-MMA-AN terpolymer polymer heat-resistant modifier into the mixing in a container;

[0041] Step 2: Use a high-speed shearing dispersing emulsifier to disperse the mixture for 5 minutes to 8 minutes;

[0042] Step 3: Preheat the mold to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com