Lignin-containing biodegradable polyester compound bead foaming material with high crystallization rate and preparation method thereof

A biodegradable polyester and bead foaming technology, applied in the field of biodegradable polymer materials, can solve the problems of low foaming ratio, low crystallization speed, and performance degradation of plastic products, so as to widen the foaming range and improve the foaming rate. Foam performance, effect of increasing crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) After drying at 70°C for 10 hours MAH (10 parts) and DCP (3 parts) are melt blended in a twin-screw extruder, which contains five temperature zones, and the temperatures from zone 1 to zone 5 are 130°C, 135°C, 140°C, 135°C and 130°C , the extrusion twin-screw speed is 80rpm; this process is repeated three times, and the coarse MAH-g-PBAT particles are obtained after being pelletized by a pelletizer; the thick MAH-g-PBAT particles are dissolved in methylene chloride until completely dissolved, and the solution After being clear, it is then poured into excess ultrapure water for precipitation to remove unreacted maleic anhydride (MAH) and dicumyl peroxide (DCP), and the resulting precipitate is MAH with a grafting ratio of 1.24 after purification -g-PBAT masterbatch;

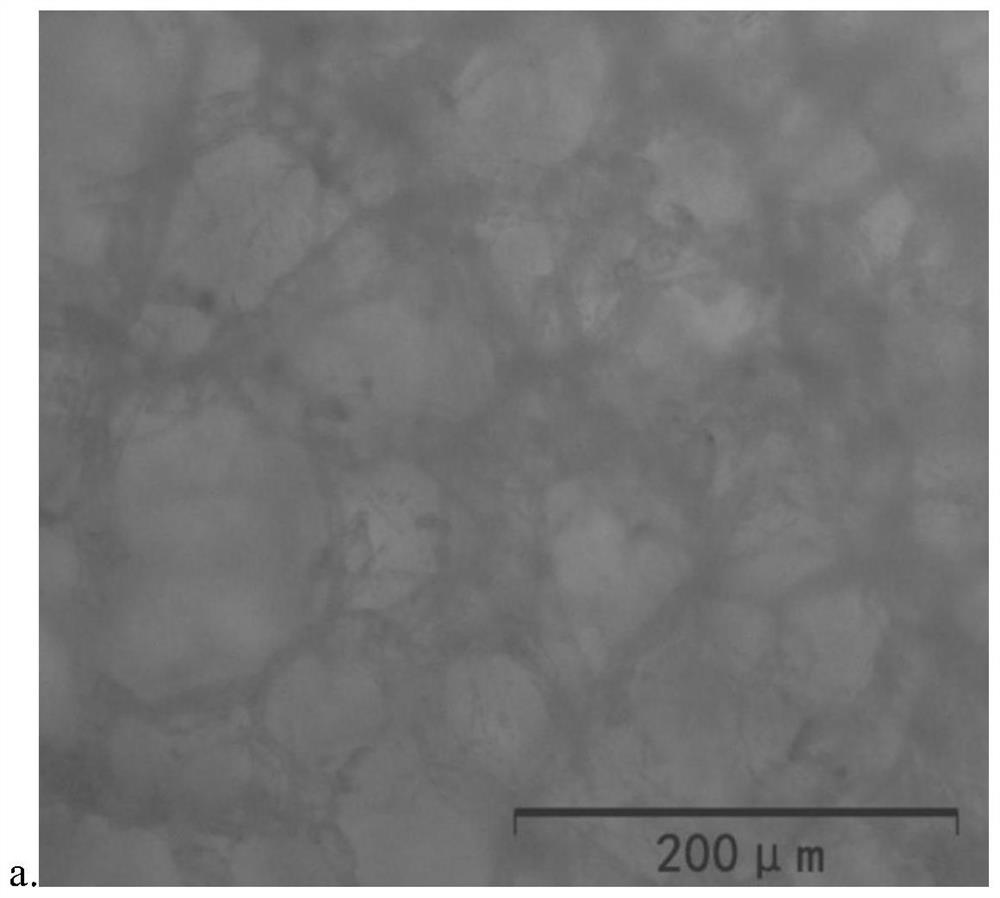

[0051] (2) Dry PLA-LX175 (30 parts) at 70°C for 10 hours, MAH-g-PBAT masterbatch (6 parts), kraft lignin with a particle size of 2 μm (20 parts), chain extender ADR-4468 (2 parts) is extruded in...

Embodiment 2

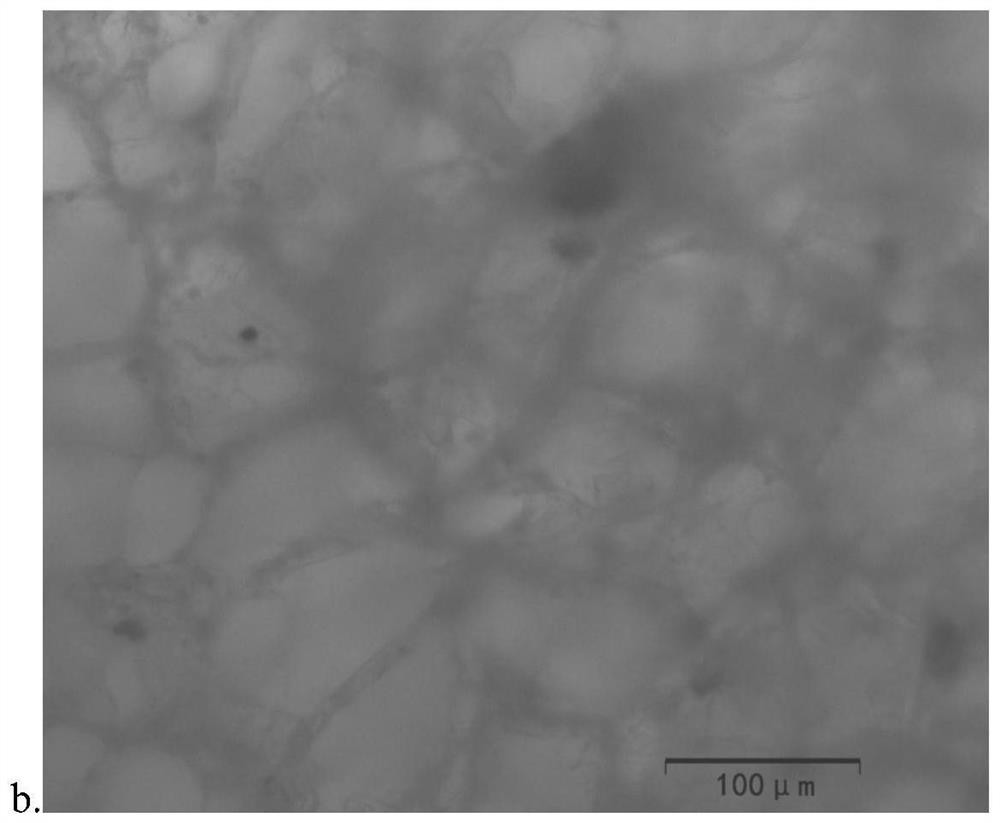

[0075] The preparation method of MAH-g-PBAT masterbatch is identical with embodiment 1. After drying at 70°C for 10 hours PLA-LX175 (30 parts), MAH-g-PBAT masterbatch (6 parts), kraft lignin with a particle size of 2 μm (10 parts), chain extender ADR-4468 (2 parts) is extruded in a twin-screw underwater pelletizing extruder, which contains nine temperature zones, and the temperatures from zone one to zone nine are 155°C, 180°C, 180°C, 185°C, 185°C, 190°C, 190°C, 185°C, 190°C, die head temperature 230°C, screw speed 80 rpm; pelletizer speed 1500 rpm, cut into 5 mg pellets.

[0076] Place the obtained granules in a supercritical foaming machine to ensure that the total volume of the granules does not exceed 1 / 3 of the volume of the container (3000cm 3 ), with 20MPa supercritical CO 2 As a foaming agent, it is saturated at 112°C for 10 minutes, and the pressure is released at a rate of 20 MPa / s to obtain a biodegradable composite foaming material.

Embodiment 3

[0078] The preparation method of MAH-g-PBAT masterbatch is identical with embodiment 1. After drying at 70°C for 10 hours PLA-LX175 (30 parts), MAH-g-PBAT masterbatch (6 parts), kraft lignin with a particle size of 2 μm (40 parts), chain extender ADR-4468 (2 parts) is extruded in a twin-screw underwater pelletizing extruder, which contains nine temperature zones, and the temperatures from zone 1 to zone 9 are 155°C, 180°C, 180°C, 185°C, 185°C, 190°C, 190°C, 185°C, 190°C, die head temperature 230°C, screw speed 80 rpm; pelletizer speed 1500 rpm, cut into 5 mg pellets.

[0079] Place the obtained granules in a supercritical foaming machine to ensure that the total volume of the granules does not exceed 1 / 3 of the volume of the container (3000cm 3 ), with 20MPa supercritical CO 2 As a foaming agent, it is saturated at 112°C for 10 minutes, and the pressure is released at a rate of 20 MPa / s to obtain a biodegradable composite foaming material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com