Preparation method of monodispersed mesoporous silica, and nano-composite foaming agent as well as preparation method and application thereof

A mesoporous silica and nanocomposite technology, applied in the direction of silica, silica, etc., can solve the problem that the foaming efficiency and quality need to be further improved, the nucleation point of the composite foaming agent needs to be improved, and the cell size is difficult to control. and other problems, to achieve the effect of small cells, excellent dispersion, and good foaming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0101] Preparation of mesoporous silica:

[0102] The mesoporous silica was obtained by polymerization-induced colloidal coagulation method, and the elemental silicon powder was activated by immersing in hot water at 70°C for 10 minutes, and then centrifuged to obtain activated elemental silicon powder. Then add 200g of sodium hydroxide solution with a mass concentration of 0.5% into a three-necked flask, heat it to 60-80°C, add activated silicon powder, stir and react for 12-24h, then separate the reaction mixture, and the separated solution is It is the primary particle of silica sol. The primary particles of the obtained silica sol are used as the mother liquor, and the same steps as the preparation of primary particles are adopted to obtain silica sols with different particle sizes by supplementing silicon powder and 0.5% sodium hydroxide solution by mass fraction. Supplementary silicon powder and sodium hydroxide solution consumption and the corresponding raw material el...

Embodiment 1

[0115] The preparation of embodiment 1 silica sol (primary particle)

[0116] Add 200g of sodium hydroxide solution with a concentration of 0.5% into a three-necked flask, heat it to 70°C, add 21g of activated silicon powder, stir and react for 12 hours, and centrifuge the reaction mixture. The separated solution is the primary particle of silica sol Silica sol, its mass concentration is 10%.

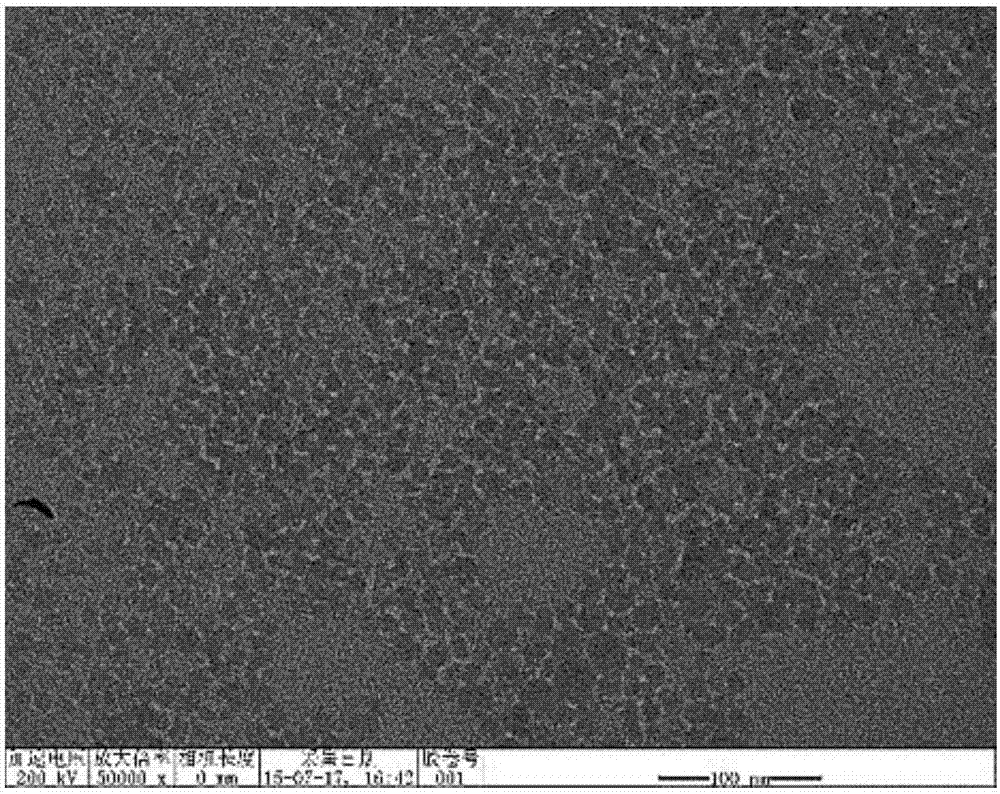

[0117] Depend on Figure 1-a As shown, the primary particle size of silica sol is 15nm.

Embodiment 2

[0118] The preparation of embodiment 2 silica sol (embodiment 1 silica sol carries out 2 times of silicon replenishment)

[0119] The silica sol obtained in Example 1 was used as the mother liquor, and 50 mL of the mother liquor was taken, and 5.25 g of elemental silicon powder after activation and 50 g of sodium hydroxide solution with a mass fraction of 0.5% were added to it for the first time, heated to 70°C, and stirred for 12 hours. Afterwards, the reaction mixture was centrifuged to obtain silica sol. Using this silica sol as the mother liquor, add 11.5g of elemental silicon powder after activation and 100g of sodium hydroxide solution with a mass fraction of 0.5% to it for the second time, heat to 70°C, stir and react for 12 hours, and then centrifuge the reaction mixture to obtain silicon Sol, its mass concentration is: 20%.

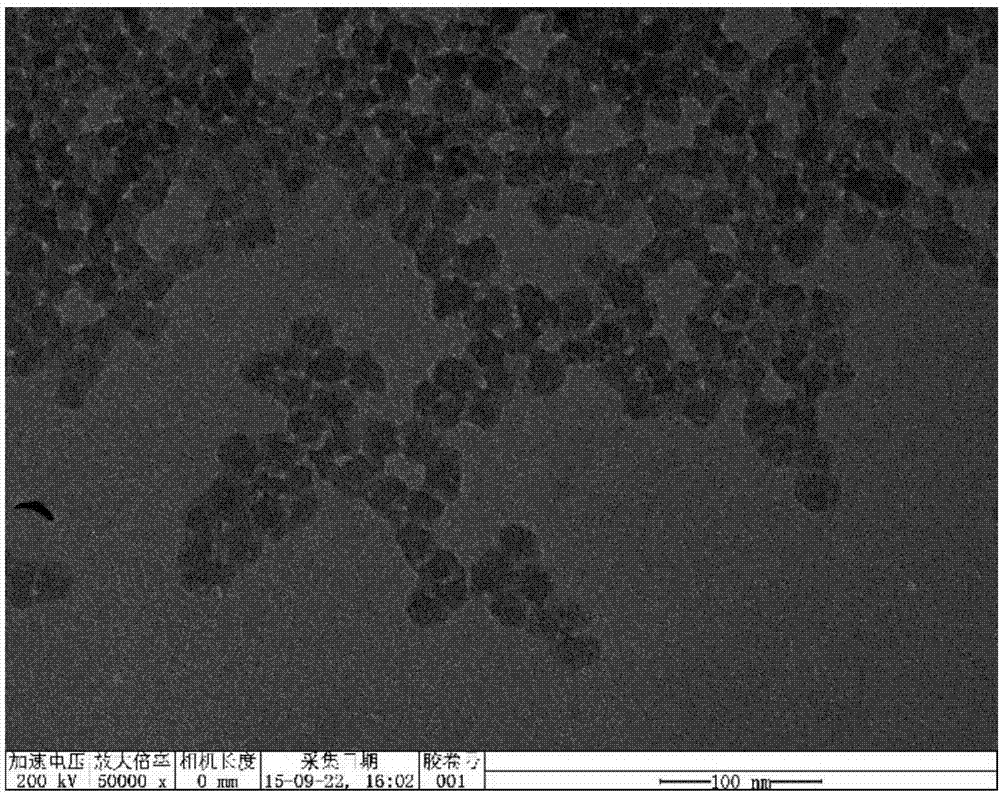

[0120] Depend on Figure 1-b As shown, the primary particle size of silica sol is 25nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com