Micropore polymethacrylimide foam with high thermal deformation temperature and preparing method thereof

A technology of polymethacrylimide and deformation temperature, which is applied in the field of small-hole polymethacrylimide foam with high heat distortion temperature and its preparation, and can solve the problems of low foam temperature resistance and low heat distortion temperature , to achieve high heat resistance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

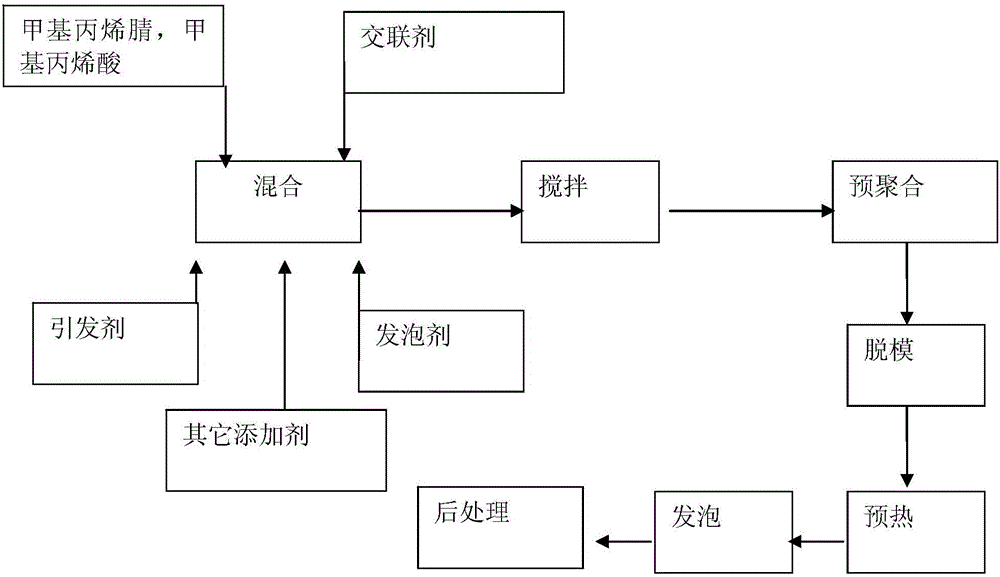

[0046] Such as figure 1 Shown is the preparation process flow chart of the small-pore polymethacrylimide foam of the present invention, the preparation method of the high heat distortion temperature small-hole polymethacrylimide foam of the present invention, comprising the following steps:

[0047] (1), mix methacrylic acid MAA, acrylonitrile AN, initiator, foaming agent, nucleating agent, crosslinking agent and heat-resistant additive uniformly, obtain reaction solution;

[0048] (2), the annular bar that elastic material is prepared is fixed on a flat plate, and annular bar surrounds the annular frame of required shape along the inner side of plate edge, the reaction solution that step (1) is obtained is poured in described annular frame, and Cover another flat plate on the ring frame, and obtain the reaction device after being clamped by a clamp;

[0049] The elastic material is rubber, specifically PVC strips, EPDM strips or silicone rubber strips; the flat plate is a gl...

Embodiment 1

[0059] High heat distortion temperature small cell polymethacrylimide foam, which is obtained by mixing and reacting the following components:

[0060] Monomer: methacrylic acid (MAA), the number of parts by mass is 35;

[0061] Monomer: methacrylonitrile (MAN), the number of parts by mass is 65;

[0062] Initiator: azo-bis(4-cyanovaleric acid), the number of parts by mass is 3;

[0063] Foaming agent: methyl urea, the number of parts by mass is 5;

[0064] Nucleating agent: magnesium oxide, the mass fraction is 1;

[0065] Crosslinking agent: triallyl cyanurate, the number of parts by mass is 2;

[0066] Heat-resistant additive: DMMP, 5 parts by mass.

[0067] The preparation method of above-mentioned polymethacrylimide foam, it adopts following steps to carry out successively:

[0068] (1) The monomer methacrylic acid and methacrylonitrile, initiator, foaming agent, nucleating agent, crosslinking agent, heat-resistant additive are weighed according to metering, and unif...

Embodiment 2

[0075] High heat distortion temperature small cell polymethacrylimide foam, which is obtained by mixing and reacting the following components:

[0076] Monomer: methacrylic acid (MAA), the number of parts by mass is 45;

[0077] Monomer: methacrylonitrile (MAN), the number of parts by mass is 55;

[0078] Initiator: azo-bis(4-cyanovaleric acid), 1.5 parts by mass; azobisisobutyronitrile, 0.1 parts by mass;

[0079] Foaming agent: urea, the number of parts by mass is 8;

[0080] Nucleating agent: calcium oxide, the number of parts by mass is 4;

[0081] Crosslinking agent: allyl methacrylate, the number of parts by mass is 0.5;

[0082] Heat-resistant additive: tribromophenylmaleimide, 10 parts by mass.

[0083] The preparation method of above-mentioned polymethacrylimide foam, it adopts following steps to carry out successively:

[0084] (1) The monomer methacrylic acid and methacrylonitrile, initiator, foaming agent, nucleating agent, crosslinking agent, heat-resistant a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com