Core layer material of halogen-free flame retardant aluminum-plastic plate and manufacturing method thereof

A flame-retardant aluminum-plastic panel and a manufacturing method, which are applied to the core layer material for halogen-free flame-retardant aluminum-plastic panel and its manufacturing field, can solve the problems of reduced extrusion efficiency, influence of core material strength, foaming failure, and the like. achieve an environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

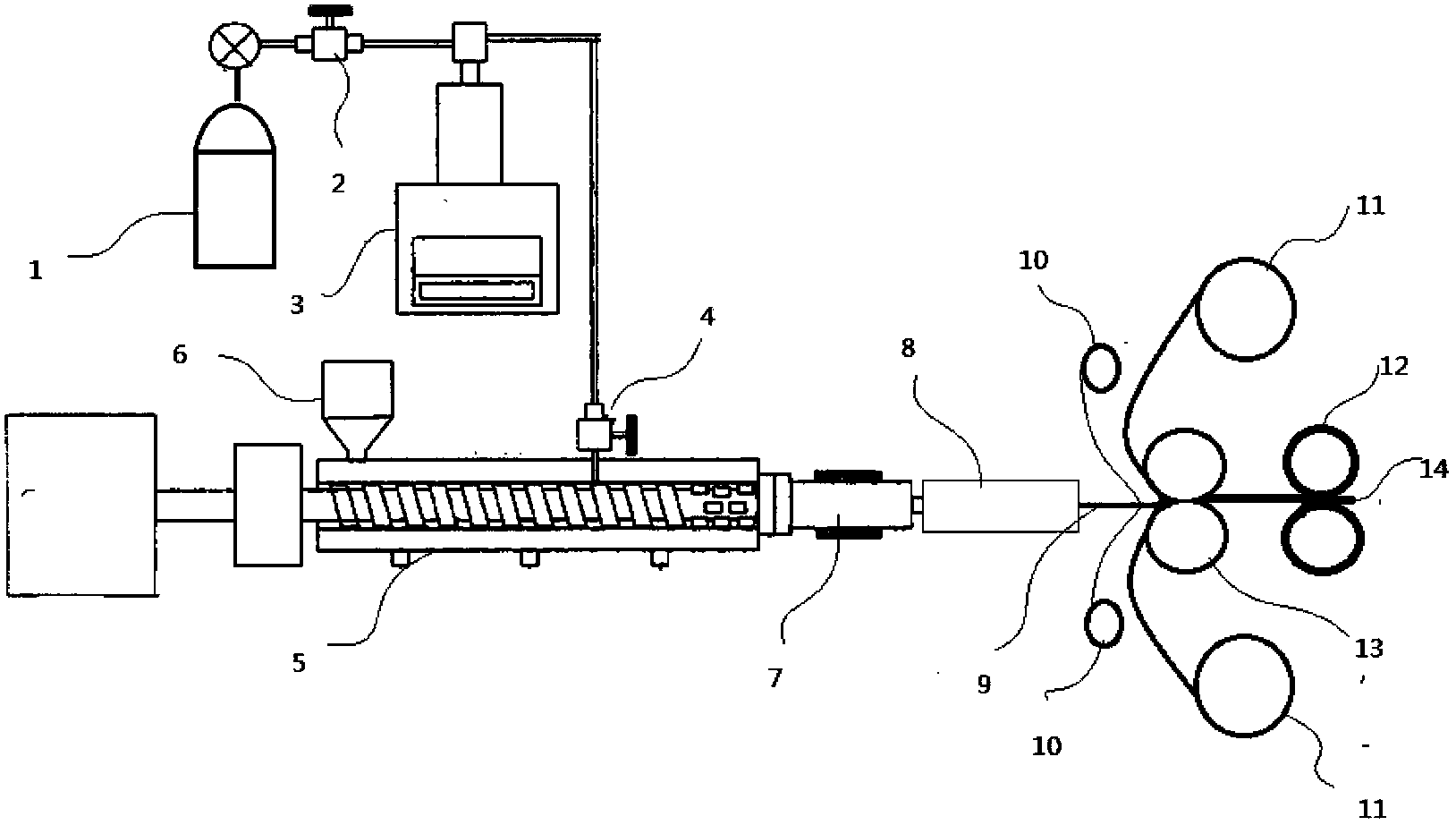

[0027] like figure 1 As shown, 39 parts of low-density polyethylene (LDPE), 60 parts of surface-treated activated magnesium hydroxide (Mg(OH) 2 ) and 1 part of ethylene bisstearamide (EBS) were mixed uniformly in a high mixer to obtain extruded materials. The mixed material is fed into the screw extruder 5 through the hopper 6, and the barrel temperature of the screw extruder is set at 200 degrees to melt the material. The liquid carbon dioxide stored in the liquid storage tank 1 passes through the pressure control valve 2 to control the pressure of the carbon dioxide at the required pressure of 8.5 MPa when the carbon dioxide is in a critical state, and the gas in the critical state is sent to the pressure control valve 4 by the forward metering pump 3 After the pressure of the supercritical carbon dioxide is further increased to 10.5Mpa, the carbon dioxide in the critical state is delivered to the screw extruder 5 quantitatively and enters the screw extruder 5 through the g...

Embodiment 2

[0031] like figure 1 As shown, 30 parts of linear low-density polyethylene (LDPE), 9 parts of ethylene-vinyl acetate copolymer (EVA), 50 parts of surface-treated activated magnesium hydroxide (Mg(OH) 2 ), 10 parts of surface-treated aluminum hydroxide (Al(OH) 3 ), 1 part of fluoropolymer (PPA) is mixed uniformly in a high mixer to obtain extruded materials. The mixed material is fed into the screw extruder 5 through the hopper 6, and the barrel temperature of the screw extruder is set at 190 degrees to melt the material. The liquid nitrogen stored in storage tank 1 passes through pressure control valve 2 so that the pressure of nitrogen is controlled at the required pressure of 24.5 MPa when nitrogen is in a critical state, and the nitrogen in critical state is sent to guide pressure control valve 4 by forward metering pump 3, further After the pressure of the supercritical nitrogen is increased to 32.5Mpa, a certain amount of nitrogen in a critical state is delivered to the...

Embodiment 3

[0033] like figure 1 As shown, 30 parts of ethylene-vinyl acetate copolymer (EVA), 5 parts of low-density polyethylene (LDPE), 64 parts of surface-treated activated aluminum hydroxide (Al(OH) 3), 1 part of silicone is mixed uniformly in a high mixer to obtain extruded materials. The mixed material is fed into the screw extruder 5 through the hopper 6, and the barrel temperature of the screw extruder is set at 180 degrees to melt the material. The liquid nitrogen gas stored in storage tank 1 passes through pressure control valve 2 to control the pressure of nitrogen gas at the required pressure of 24.5 MPa when nitrogen gas is in a critical state, and the gas in critical state is sent to guide pressure control valve 4 by forward metering pump 3, further After the pressure of the supercritical nitrogen is increased to 35Mpa, a certain amount of nitrogen in a critical state is delivered to the screw extruder 5 and enters the screw extruder 5 through the gas injection control val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com