Cold patch asphalt mixture and preparation method thereof

A technology of cold patching asphalt and mixture, which is applied in the field of asphalt mixture, which can solve the problems of low early strength, limit the popularization and application of cold patching technology, and slow forming speed, so as to improve water stability and high temperature stability, and reduce pavement secondary Secondary disease, the effect of improving the quality of pavement repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

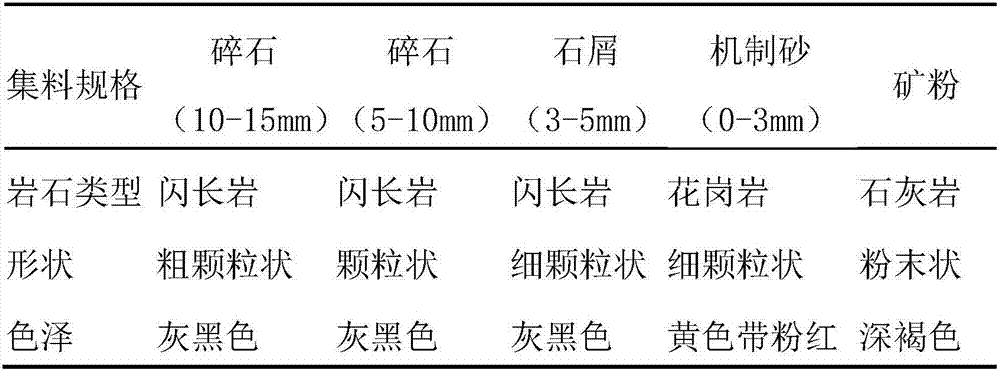

Method used

Image

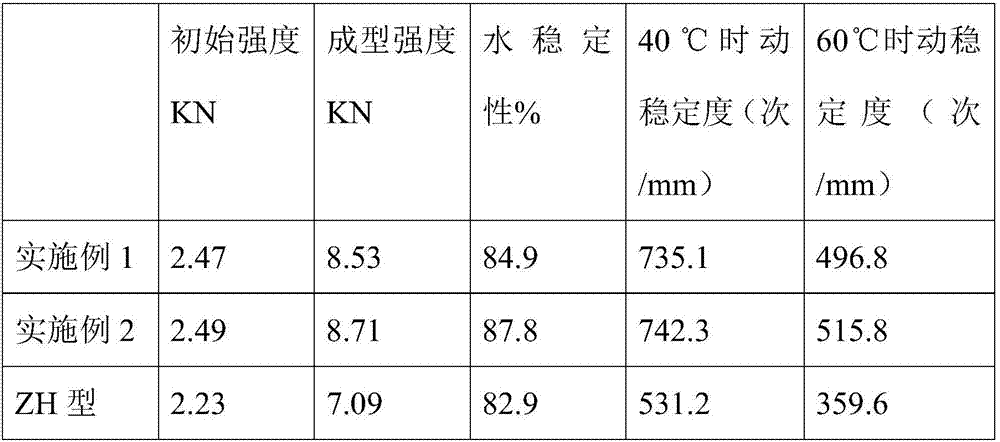

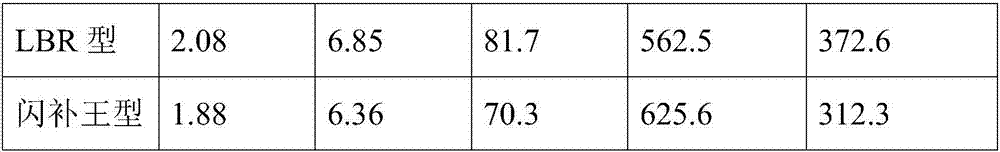

Examples

preparation example Construction

[0044] A preparation method for cold-patch asphalt mixture, specifically comprising the following steps:

[0045] 1), in parts by weight: 100 parts of base asphalt, 23-25 parts of thinner, 3-5 parts of tackifier, 0.7-0.9 parts of anti-stripping agent, 3-4 parts of water-based epoxy emulsion, water-based epoxy curing 1 part of agent; first dehydrate the base asphalt, then add diluent, tackifier and anti-stripping agent in order according to the parts by weight and mix evenly, then add water-based epoxy emulsion and water-based epoxy curing agent and mix evenly to obtain cold-patch asphalt liquid;

[0046] 2), and then mix the cold patched asphalt liquid and the aggregate at 60-70°C to obtain the mixture A;

[0047] 3) Finally, add mineral powder to the mixture A and mix evenly to obtain the cold patch asphalt mixture.

[0048] Concretely, in step 1), first base asphalt is subjected to heat dehydration treatment,

[0049] Dilute the dehydrated base asphalt in the container ...

Embodiment 1

[0056] 1. In parts by weight, heat 100 parts of 70# road petroleum asphalt to about 130°C-150°C, then dehydrate and cool down to 110°C-120°C;

[0057] 2. Add 23 parts of 0# diesel oil to the dehydrated base asphalt in the container, stir while adding, use a high-speed shearer with a rotation speed of 2000r / min to stir for 10min to 15min, and keep the constant temperature at 100°C to 110°C to make a mixture B is ready for use;

[0058] 3. Add 3 parts of terpene resin and 0.7 parts of PA-I anti-stripping agent to the mixture B, through high-speed shearing or colloidal grinding, add while stirring to ensure that the additive can be fully dissolved in the diluted asphalt, and stir for 10 minutes to 15 minutes , at this time, the asphalt liquid should be cooled to below 100°C, and kept at a constant temperature of 80°C to 90°C to prepare mixture C for use;

[0059] 4. Add 3 parts of EP-20, 1 part of aliphatic polyamine and 1 part of 0# diesel oil to the mixture C, mix and stir in ...

Embodiment 2

[0064] 1. In parts by weight, heat 100 parts of 70# road petroleum asphalt to about 130°C-150°C, then dehydrate and cool down to 110°C-120°C;

[0065] 2. Add 23 parts of 0# diesel oil to the dehydrated base asphalt in the container, stir while adding, use a high-speed shearer with a rotation speed of 2000r / min to stir for 10min to 15min, and keep the constant temperature at 100°C to 110°C to make a mixture B is ready for use;

[0066] 3. Add 3 parts of terpene resin and 0.7 parts of PA-I anti-stripping agent to the mixture B, through high-speed shearing or colloidal grinding, add while stirring to ensure that the additive can be fully dissolved in the diluted asphalt, and stir for 10 minutes to 15 minutes , at this time, the asphalt liquid should be cooled to below 100°C, and kept at a constant temperature of 80°C to 90°C to prepare mixture C for use;

[0067] 4. Add 4 parts of EP-20, 1 part of aliphatic polyamine and 1 part of 0# diesel oil to the mixture C, mix and stir in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com