Electrochromic multi-layered transparent conductive thin film and preparation method therefor

A transparent conductive film, electrochromic technology, applied in cable/conductor manufacturing, conductive layer on insulating carrier, coating and other directions, can solve problems such as hindering Ag electron exchange, film loss of conductivity, etc., to achieve fast film growth rate , The effect of high coloring efficiency and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

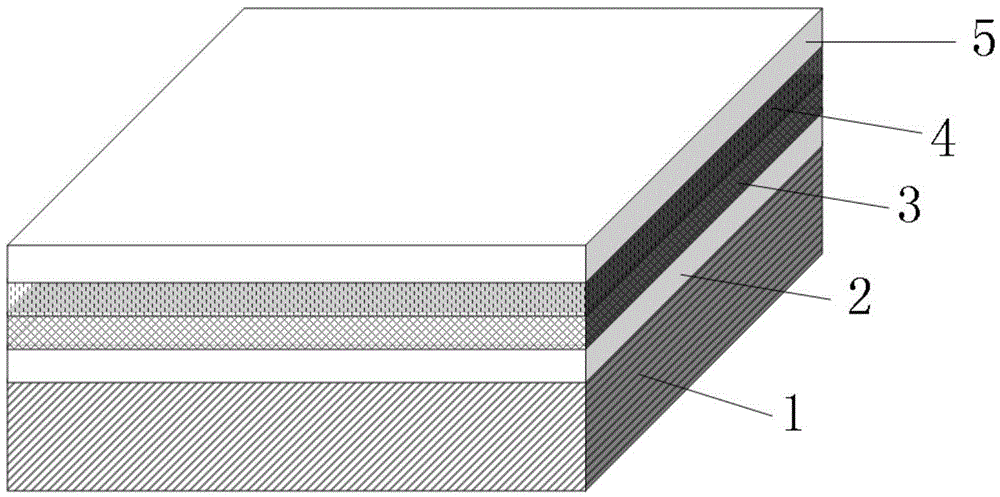

[0027] In this embodiment, an electrochromic multilayer transparent conductive film is provided, and its structure is as follows: figure 1 As shown, including the substrate, the first WO 3 Thin film layer, Ag conductive layer, W buffer layer and second WO 3 Thin film layer, first WO 3 Thin film layer, Ag conductive layer, W buffer layer and second WO 3 The thickness of the film layer is 45nm, 10-12nm, 2-3nm and 45nm respectively, and the substrate adopts standard electronic white glass.

[0028] Its preparation method comprises the following steps:

[0029] 1) Prepare the first WO 3 Thin film layer: evacuate the vacuum chamber (~5.0×10 -4 Pa), then pass in argon, adjust the argon pressure (1.0Pa), then turn on the radio frequency power switch, and then pass in oxygen after the target glows, adjust the flow of argon and oxygen (40:60sccm), so that the air pressure in the vacuum chamber is constant (4.0×10 -1 Pa), adjust the sputtering power (200W), and then perform pre-s...

Embodiment 2

[0035] The electrochromic multilayer transparent conductive film with the same structure as in Example 1 was prepared by the following steps, specifically:

[0036] 1) Prepare the first WO 3 Thin film layer: evacuate the vacuum chamber (~5.0×10 -4 Pa), then pass in argon, adjust the argon pressure (1.0Pa), then turn on the radio frequency power switch, and then pass in oxygen after the target glows, adjust the flow of argon and oxygen (40:60sccm), so that the air pressure in the vacuum chamber is constant (4.0×10 -1 Pa), adjust the sputtering power (200W), and then perform pre-sputtering cleaning (10 minutes) on the W target, then turn the substrate platform to the top of the target, adjust the sputtering time (18 minutes), and place on the glass substrate WO 3 film;

[0037] 2) Prepare the Ag conductive layer: adjust the argon flow rate (60sccm) to fix the air pressure in the vacuum chamber (3.4×10 -1 Pa), and then turn on the DC power switch. After the target glows, adj...

Embodiment 3

[0041] The electrochromic multilayer transparent conductive film with the same structure as in Example 1 was prepared by the following steps, specifically:

[0042] 1) Prepare the first WO 3 Thin film layer: evacuate the vacuum chamber (~5.0×10 -4 Pa), then pass in argon, adjust the argon pressure (1.0Pa), then turn on the radio frequency power switch, and then pass in oxygen after the target glows, adjust the flow of argon and oxygen (40:60sccm), so that the air pressure in the vacuum chamber is constant (4.0×10 -1 Pa), adjust the sputtering power (200W), and then perform pre-sputtering cleaning (10 minutes) on the W target, then turn the substrate platform to the top of the target, adjust the sputtering time (18 minutes), and place on the glass substrate WO 3 film;

[0043] 2) Prepare the Ag conductive layer: adjust the argon flow rate (60sccm) to fix the air pressure in the vacuum chamber (3.4×10 -1 Pa), and then turn on the DC power switch. After the target glows, adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com