Bridge expansion joint fast reparation material

A technology for repairing materials and expansion joints, which is applied in the field of rapid repair materials for bridge expansion joints. It can solve the problems of long maintenance period, poor bonding, and susceptibility to impact fracture, etc., and achieve good steric resistance effect and good construction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

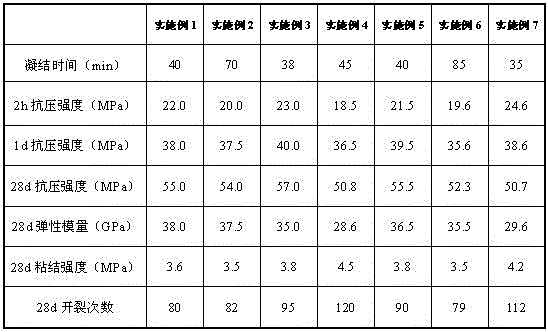

Examples

Embodiment 1

[0027] Embodiment 1 A kind of bridge expansion joint rapid repair material, it is made up of two kinds of components of A and B; Wherein

[0028] A consists of the following components in parts by weight: 25 parts of rapid hardening sulfoaluminate cement, 5 parts of ordinary portland cement, 3 parts of anhydrite, 3 parts of silica fume, 60 parts of quartz sand, 0.5 parts of water reducer, boric acid 0.5 parts, fiber 3 parts;

[0029] B consists of the following components in parts by weight: 35 parts of carboxylated styrene-butadiene latex, 0.5 parts of lithium salt, 0.5 part of lithium salt defoamer, and 65 parts of water.

[0030] Among them: the strength grade of rapid hardening sulfoaluminate cement is 42.5 or 52.5. The strength grade of ordinary Portland cement is 52.5. The specific surface area of silica fume is 20000m 2 / kg. The water reducer is a polycarboxylate high performance water reducer. The fiber refers to the mixture of polypropylene fibers with a diamet...

Embodiment 2

[0036] Embodiment 2 A kind of bridge expansion joint rapid repair material, it is made up of two kinds of components of A and B; Wherein

[0037] A is composed of the following components in parts by weight: 25 parts of rapid hardening sulfoaluminate cement, 5 parts of ordinary portland cement, 3 parts of anhydrite, 1.5 parts of silica fume, 60 parts of quartz sand, 0.5 parts of water reducer, boric acid 1 part, fiber 2 parts;

[0038] B consists of the following components in parts by weight: 45 parts of carboxylated styrene-butadiene latex, 0.5 parts of lithium salt, 0.5 part of lithium salt defoamer, and 59 parts of water.

[0039] Wherein: rapid-hardening sulfoaluminate cement, ordinary Portland cement, silica fume, water reducing agent, and fiber are the same as in Example 1.

[0040] The using method of this bridge expansion joint rapid repair material is the same as embodiment 1.

Embodiment 3

[0041] Embodiment 3 A kind of bridge expansion joint rapid repair material, it is made up of two kinds of components of A and B; Wherein

[0042] A consists of the following components in parts by weight: 28 parts of rapid hardening sulfoaluminate cement, 10 parts of ordinary portland cement, 1 part of anhydrite, 1 part of silica fume, 55 parts of quartz sand, 1 part of water reducer, boric acid 1 part, 3 parts fiber;

[0043] B consists of the following components in parts by weight: 40 parts of carboxylated styrene-butadiene latex, 0.75 parts of lithium salt, 0.75 parts of lithium salt defoamer, and 58.5 parts of water.

[0044] Wherein: rapid-hardening sulfoaluminate cement, ordinary Portland cement, silica fume, water reducing agent, and fiber are the same as in Example 1.

[0045] The using method of this bridge expansion joint rapid repair material is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com