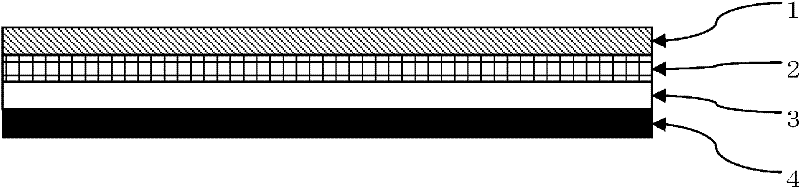

Patch material

A technology for pasting materials and adhesives, applied in viscous dressings, dressings, adhesives, etc., can solve problems such as low moisture permeability, weak bonding, and increased exfoliation of cutin, and achieve the effect of excellent adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

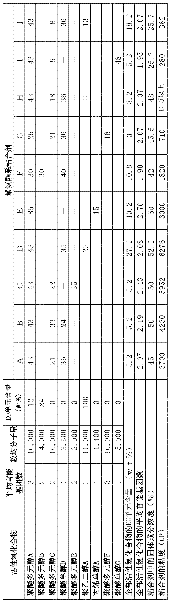

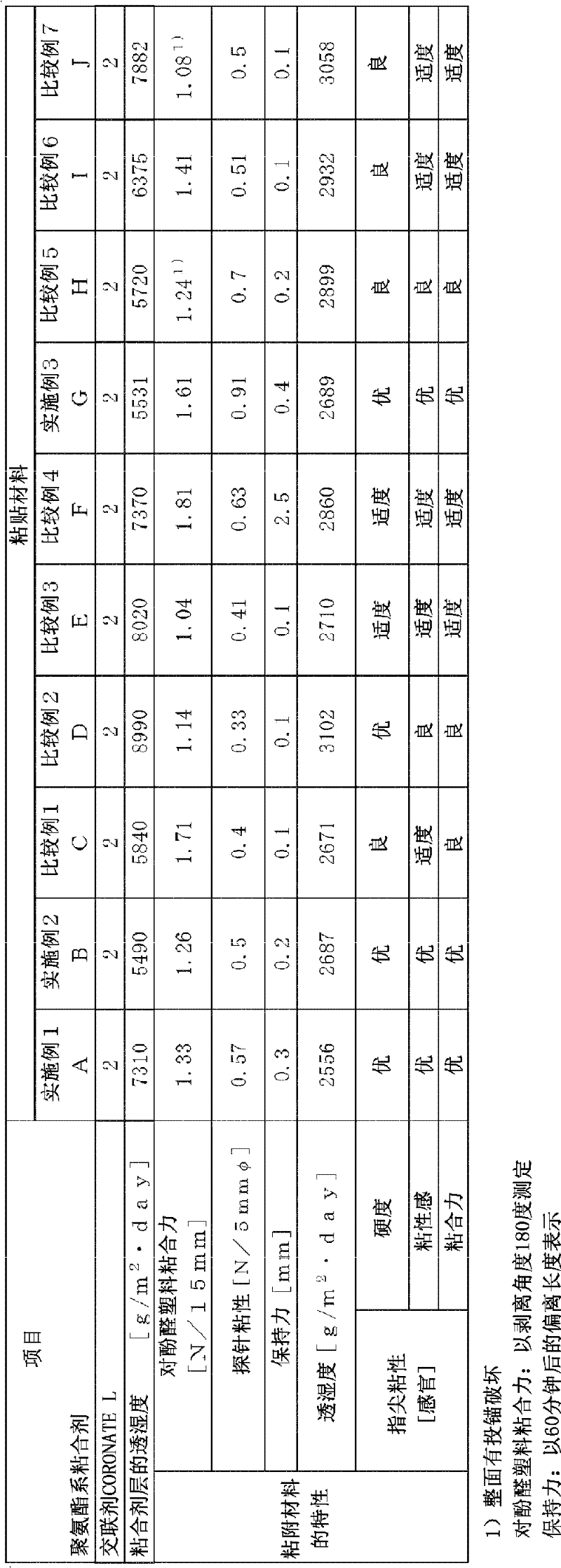

[0072] The present invention will be described in detail below using examples, but the present invention is not limited thereto. Parts and % in the following synthesis examples, examples, and comparative examples represent parts by mass and % by mass, respectively, in principle.

[0073] 1. Preparation of polyurethane adhesive

[0074] In the reaction vessel equipped with a thermometer, a stirrer and a cooling pipe, as shown in Table 1, add a specified amount of polyether polyol A [copolymer of EO units and propylene oxide (PO) units of glycerol as the initiator, number average Molecular weight 10,000, F=3, polyether polyol B (copolymer of EO units and PO units, number average molecular weight 4,000, F=2), polyether polyol C (polymer of PO units, number average molecular weight 10,000, F=2), polyether monool D (methanol is the polymer of the PO unit of initiator, number average molecular weight 3,500, F=1), polyether polyol E (the polymer of PO unit, number average molecular ...

Embodiment 1

[0080] 100 parts of the above-prepared polyurethane-based adhesive (A) and 2 parts of CORONATE L (manufactured by Nippon Polyurethane Industry Co., Ltd.) were uniformly mixed, defoamed, and released on a polyester film (peeled body, thickness 50 μm) Coating was performed with a knife coater so that the dry film thickness was 25 μm, and then cured and dried at 120° C. for 3 minutes. On the obtained adhesive layer, a film base material (support body, moisture permeability 3,300 g / m) of ether-based urethane resin with a thickness of 20 μm 2 ·day) and a laminated body of a polyester film (carrier) with a thickness of 40 μm facing the film substrate, and then stored in a hot air dryer at 50°C for 5 days to complete the cross-linking reaction of the adhesive layer. Paste material was made.

Embodiment 2

[0082] Except having used (B) prepared above instead of (A) as a polyurethane adhesive, it carried out similarly to Example 1, produced the adhesive material, and performed measurement and evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com