Mechanism sand dry-mixed mortar and preparation method thereof

A technology for dry-mixed mortar and machine-made sand, applied in the field of building materials, can solve the problems of unreasonable grading, large fineness modulus, poor construction, etc., and achieve the effect of improving product quality, moderate fineness and reasonable grading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

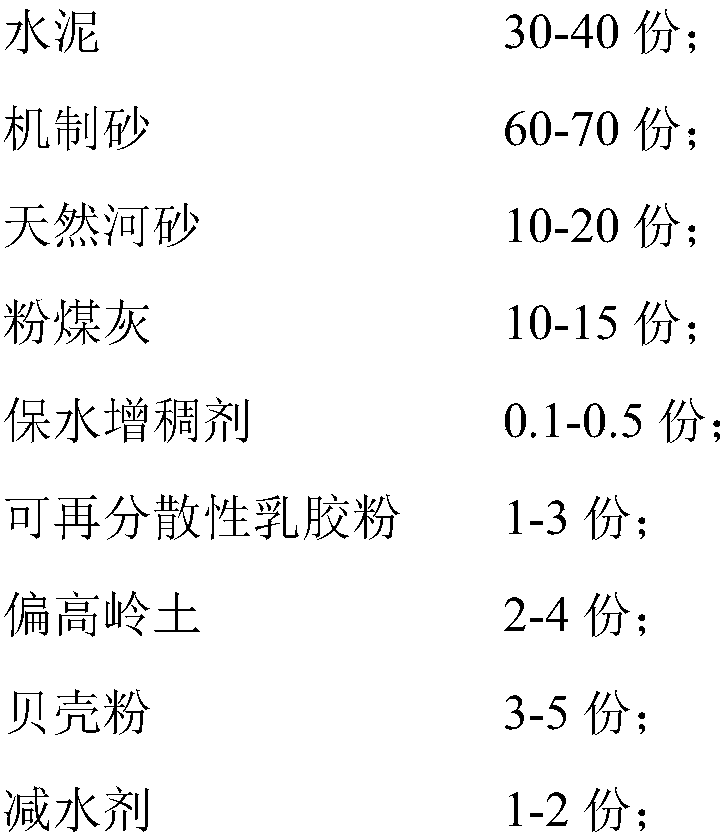

[0050] Example 1: A machine-made sand dry-mixed mortar is prepared by the following method:

[0051] S1: crush the tailings to obtain tailings sand with a particle size of 0.5-0.35mm;

[0052] S2: Partially screen out the stone powder with a particle size of less than 75 μm in the tailings sand, so that the stone powder content is 1%;

[0053] S3: Dry the machine-made sand, remove dust, control the water content of the machine-made sand to less than 0.4%, and the mud content to less than 1.0%;

[0054] S4: 30kg of cement, 60kg of machine-made sand, 10kg of natural river sand, 10kg of fly ash, 0.1kg of water-retaining thickener, 1kg of ethylene-vinyl acetate copolymer rubber powder, 2kg of metakaolin, 1kg of shell powder and 1kg of polycarboxylic acid The water reducer is dry-mixed and stirred, and the machine-made sand dry-mixed mortar is obtained by mixing evenly.

[0055] Among them, the tailings sand is medium sand in Zone II, with an average particle size of 0.5-0.35mm, ...

Embodiment 2

[0056] Example 2: A machine-made sand dry-mixed mortar is prepared by the following method:

[0057] S1: crush the tailings to obtain tailings sand with a particle size of 0.5-0.35mm;

[0058] S2: Partially screen out the stone powder with a particle size of less than 75 μm in the tailings sand, so that the stone powder content is 1%;

[0059] S3: Dry the machine-made sand, remove dust, control the water content of the machine-made sand to less than 0.4%, and the mud content to less than 1.0%;

[0060] S4: 35kg of cement, 65kg of machine-made sand, 15kg of natural river sand, 13kg of fly ash, 0.3kg of water-retaining thickener, 2kg of ethylene-vinyl acetate copolymer rubber powder, 3kg of metakaolin, 2kg of shell powder and 1.5kg of polycarboxylic acid It is a water reducing agent for dry mixing and stirring, and the machine-made sand dry-mixing mortar is obtained by mixing evenly.

[0061] Among them, the tailings sand is medium sand in Zone II, with an average particle siz...

Embodiment 3

[0062] Example 3: A machine-made sand dry-mixed mortar is prepared by the following method:

[0063] S1: crush the tailings to obtain tailings sand with a particle size of 0.5-0.35mm;

[0064] S2: Partially screen out the stone powder with a particle size of less than 75 μm in the tailings sand, so that the stone powder content is 1%;

[0065] S3: Dry the machine-made sand, remove dust, control the water content of the machine-made sand to less than 0.4%, and the mud content to less than 1.0%;

[0066] S4: 40kg of cement, 70kg of machine-made sand, 20kg of natural river sand, 15kg of fly ash, 0.5kg of water-retaining thickener, 3kg of ethylene-vinyl acetate copolymer rubber powder, 4kg of metakaolin, 3kg of shell powder and 2kg of polycarboxylic acid The water reducer is dry-mixed and stirred, and the machine-made sand dry-mixed mortar is obtained by mixing evenly.

[0067] Among them, the tailings sand is medium sand in Zone II, with an average particle size of 0.5-0.35mm, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com