Method for improving dry shrinkage resistance of cement stabilized macadam base material

A cement-stabilized gravel and base material technology, applied in the field of cement materials, can solve problems such as cracks, reducing the service life of pavement structures, and destroying the integrity and continuity of pavement structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

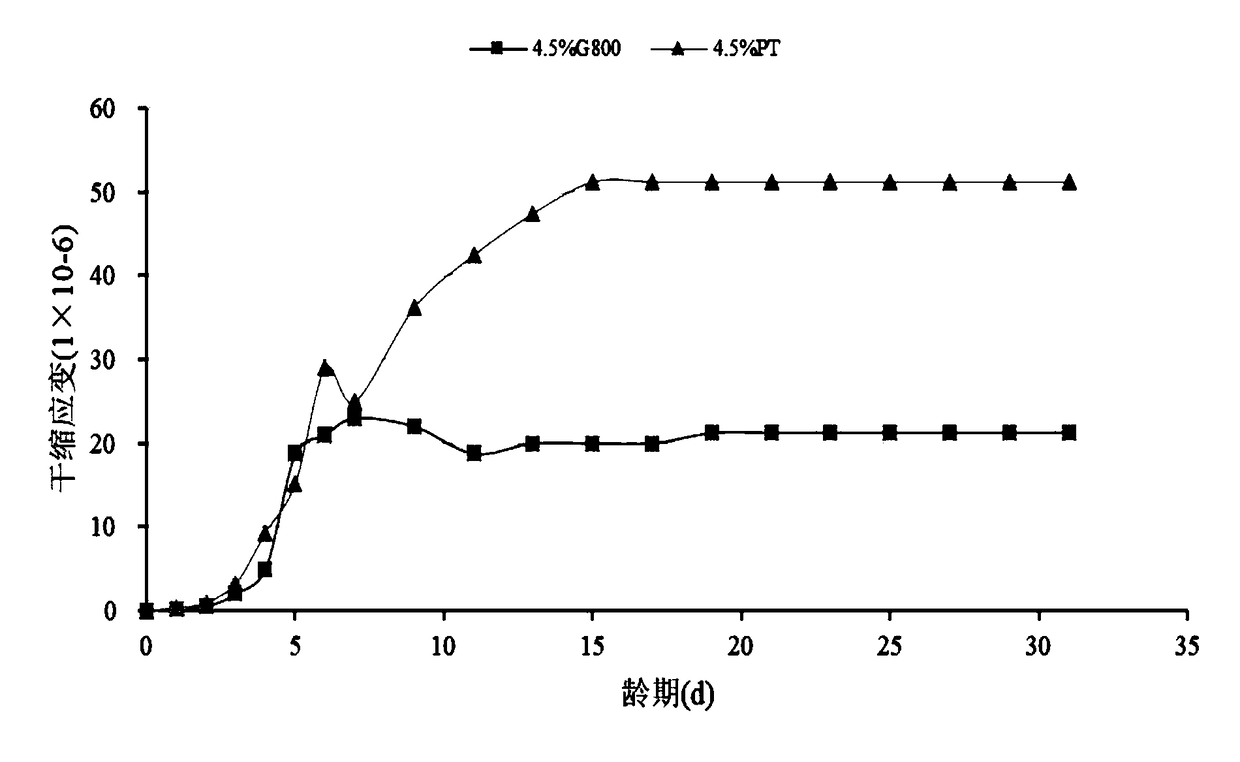

Embodiment 1

[0022] First, use three GMX800 magnetic water devices, and place them on the outer wall of a rubber tube with a diameter of 20mm in sequence according to the water flow direction marked by the magnetic water devices. device to produce magnetized water. Then according to the compaction test method (T0804-1994) of the inorganic binder stabilized material in the JTG E51-2009 "Highway Engineering Inorganic Binder Stable Material Test Regulations", carry out the cement stabilized crushed stone base material compaction test of 4.5% cement dosage, Determine optimum moisture content and maximum dry density. Then according to the determined optimal water content, ordinary water and magnetized water prepared under the above-mentioned magnetization conditions are respectively used to mix and produce cement stabilized crushed stone base material. With a compaction degree of 98%, according to JTG E51-2009 "Inorganic Binder Stable Material Test Regulations for Highway Engineering" Inorgani...

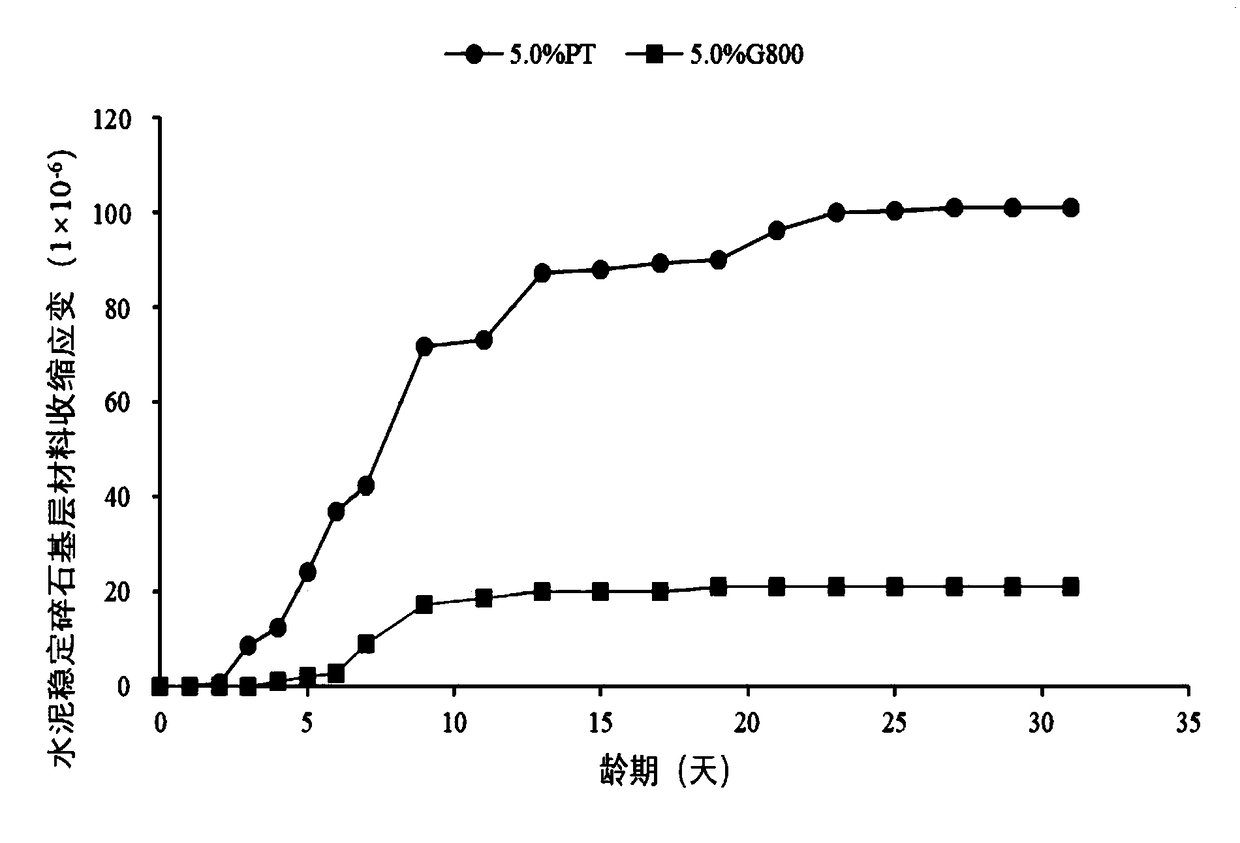

Embodiment 2

[0024] First, use three GMX800 magnetic water devices, and place them on the outer wall of a rubber tube with a diameter of 20mm in sequence according to the water flow direction marked by the magnetic water devices. device to produce magnetized water. Then according to the inorganic binder stable material compaction test method (T0804-1994) in JTG E51-2009 "Highway Engineering Inorganic Binder Stable Material Test Regulations", carry out the cement stabilized gravel base material compaction test of cement dosage 5.0%, Determine optimum moisture content and maximum dry density. Then according to the determined optimal water content, ordinary water and magnetized water prepared under the above-mentioned magnetization conditions are respectively used to mix and produce cement stabilized crushed stone base material. With a compaction degree of 98%, according to JTG E51-2009 "Inorganic Binder Stable Material Test Regulations for Highway Engineering" Inorganic Binder Stable Materi...

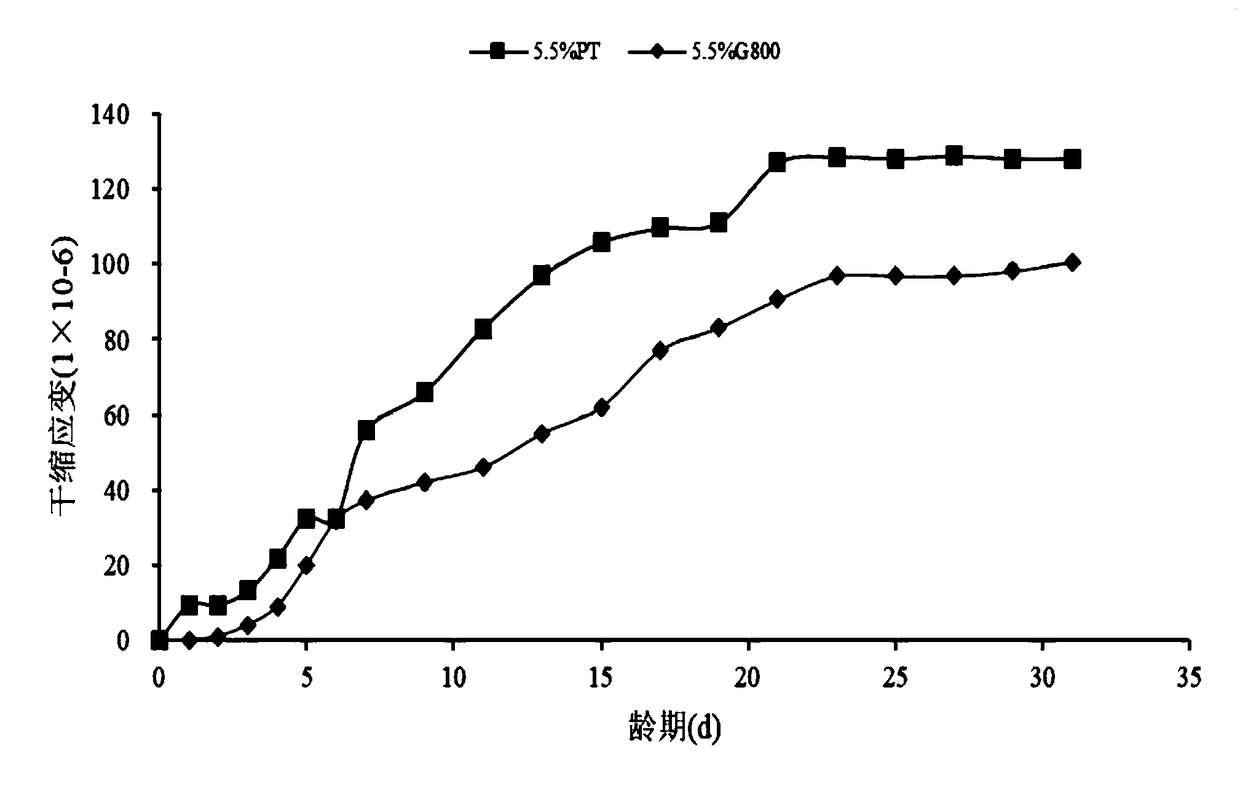

Embodiment 3

[0026] First, use three GMX800 magnetic water devices, and place them on the outer wall of a rubber tube with a diameter of 20mm in sequence according to the water flow direction marked by the magnetic water devices. device to produce magnetized water. Then according to the compaction test method (T0804-1994) of the inorganic binder stabilized material in JTG E51-2009 "Highway Engineering Inorganic Binder Stabilized Material Test Regulations", carry out the cement stabilized gravel base material compaction test of cement dosage 5.5%, Determine optimum moisture content and maximum dry density. Then according to the determined optimal water content, ordinary water and magnetized water prepared under the above-mentioned magnetization conditions are respectively used to mix and produce cement stabilized crushed stone base material. With a compaction degree of 98%, according to JTG E51-2009 "Inorganic Binder Stable Material Test Regulations for Highway Engineering" Inorganic Binde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com