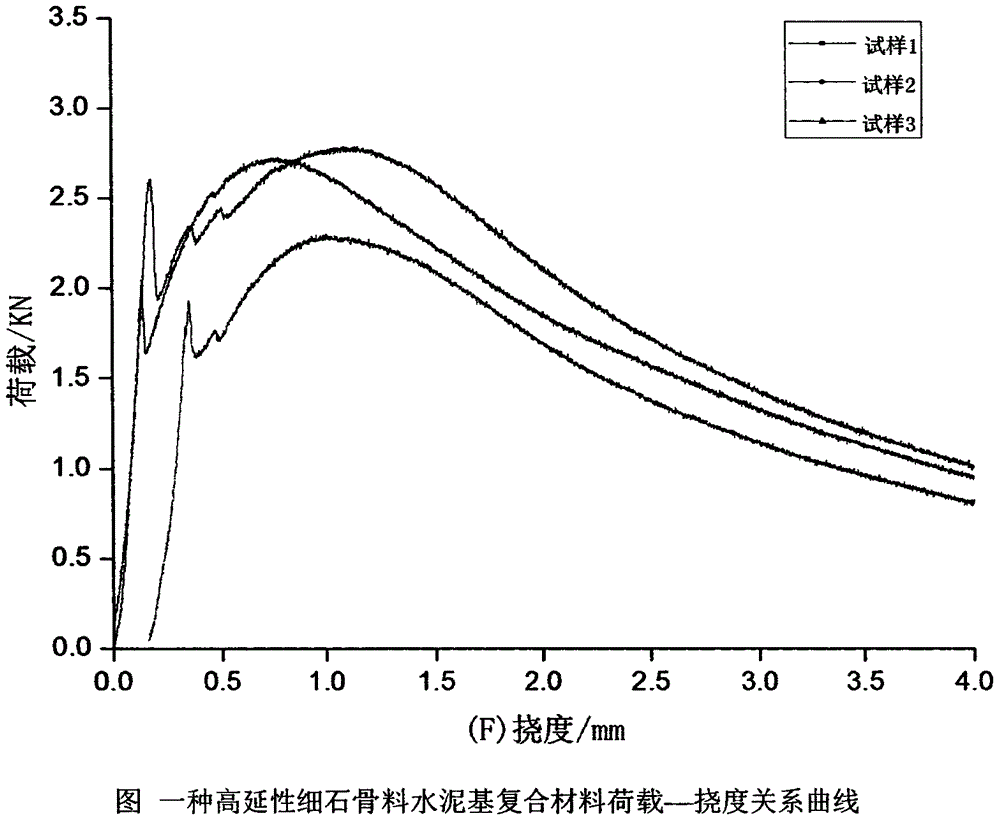

High-ductility cement-based composite material with fine stone aggregate

A composite material and high ductility technology, applied in the direction of climate change adaptation, etc., can solve the problems of poor synergistic stress, limited strength improvement, high production cost, etc., and achieve the effects of increased strength, improved work performance, and high load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A high-ductility fine stone aggregate cement-based composite material is made of raw materials with the following weight ratios: 35 parts of water, 33 parts of cement, 40 parts of composite mineral admixtures, and 10.3 parts of composite admixtures (wherein 10 parts of shrinkage reducing agent, 0.3 parts of water reducing agent), 45 parts of fine stone aggregate, and the volume ratio of polypropylene fiber is 1.5%.

Embodiment 2

[0027] A high-ductility fine stone aggregate cement-based composite material is made of raw materials with the following weight ratios: 33 parts of water, 35 parts of cement, 43 parts of composite mineral admixtures, and 9.8 parts of composite admixtures (wherein 8.6 parts of shrinkage reducing agent, 0.8 part of antirust agent, 0.4 part of water reducing agent), 45 parts of fine stone aggregate, and the volume ratio of steel fiber is 2.4%.

Embodiment 3

[0029] A high-ductility fine stone aggregate cement-based composite material is made of raw materials with the following weight ratios: 38 parts of water, 37 parts of cement, 58 parts of composite mineral admixtures, and 8.4 parts of composite admixtures (wherein 8 parts of shrinkage reducing agent, 0.4 part of antirust agent and water reducing agent), 45 parts of fine stone aggregate, and the volume ratio of basalt fiber is 1.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com