Anti-crack type rubber powder cement stabilized macadam mixture and preparation method thereof

A cement-stabilized gravel and mixture technology, which is applied in the field of pavement materials, can solve the problems of traffic load sensitivity, cracking, low stiffness and tensile strength, etc., and achieve the effects of reducing damage, improving crack resistance, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

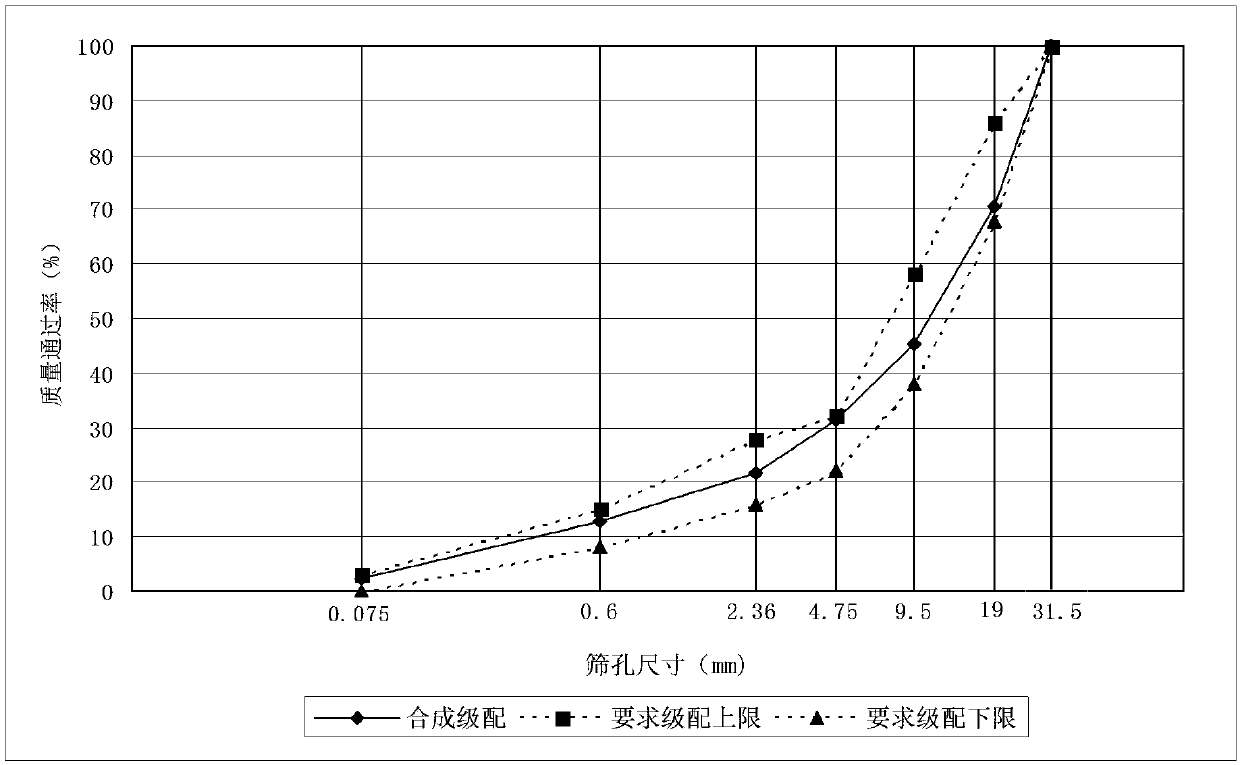

Image

Examples

Embodiment 1

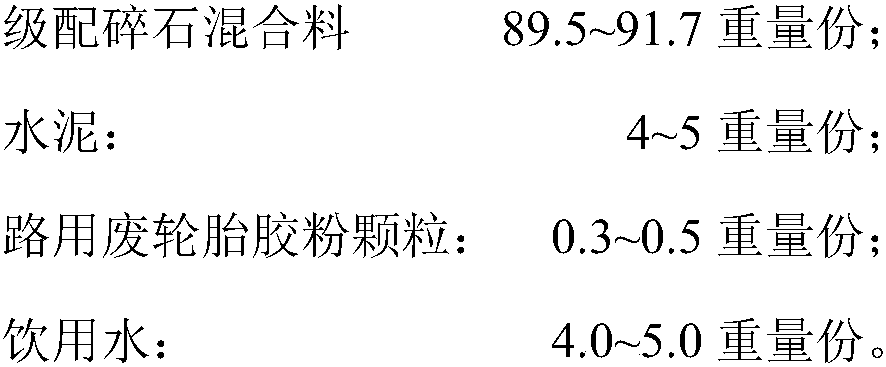

[0034] An anti-cracking rubber powder cement stabilized crushed stone mixture, characterized in that it comprises the following components by weight and number:

[0035]

[0036] The particle size of waste tire rubber powder for road use is 425 μm, that is, 40 mesh. The road-use waste tire rubber powder particles are modified rubber powder after microwave treatment of waste tire rubber powder and modification additives. Microwave radiation, extraction, and styrene soaking were used to modify the fine rubber powder of waste tires, and the modified rubber powder was measured for swelling degree, and analyzed by energy spectrum, infrared, and electron microscopy. Through modification, the styrene swelling degree of rubber powder is enhanced, the content of inorganic matter is reduced, the surface structure becomes loose, the surface area increases, and the surface active structure increases. Road waste tire rubber powder particles meet: heating loss ≤ 1.0%; ash content ≤ 15%;...

Embodiment 2

[0071] An anti-cracking rubber powder cement stabilized crushed stone mixture, characterized in that it comprises the following components by weight and number:

[0072]

[0073] The particle size of waste tire rubber powder for road use is 250 μm, that is, 60 mesh. The road-use waste tire rubber powder particles are modified rubber powder after microwave treatment of waste tire rubber powder and modification additives. Microwave radiation, extraction, and styrene soaking were used to modify the fine rubber powder of waste tires, and the modified rubber powder was measured for swelling degree, and analyzed by energy spectrum, infrared, and electron microscopy. Through modification, the styrene swelling degree of rubber powder is enhanced, the content of inorganic matter is reduced, the surface structure becomes loose, the surface area increases, and the surface active structure increases. Road waste tire rubber powder particles meet: heating loss ≤ 1.0%; ash content ≤ 15%;...

Embodiment 3

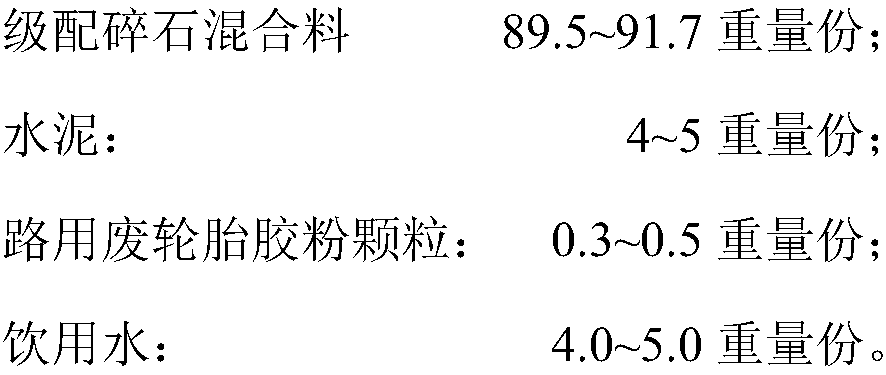

[0106] An anti-cracking rubber powder cement stabilized crushed stone mixture, characterized in that it comprises the following components by weight and number:

[0107]

[0108] The particle size of waste tire rubber powder for road use is 425 μm, that is, 40 mesh. The road-use waste tire rubber powder particles are modified rubber powder after microwave treatment of waste tire rubber powder and modification additives. Microwave radiation, extraction, and styrene immersion were used to modify the fine rubber powder of waste tires, and the modified rubber powder was measured for swelling degree, and analyzed by energy spectrum, infrared, and electron microscopy. Through modification, the styrene swelling degree of the rubber powder is enhanced, the content of inorganic substances is reduced, the surface structure becomes loose, the surface area increases, and the surface active structure increases. Road waste tire rubber powder particles meet: heating loss ≤ 1.0%; ash cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com