High-performance cement with high-content yellow phosphorus slag and production process of high-performance cement

A yellow phosphorus slag and high-performance technology is applied in the field of high-performance cement and its production process with a large amount of yellow phosphorus slag, achieving the effects of good market prospects, simple production process, and strong reaction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

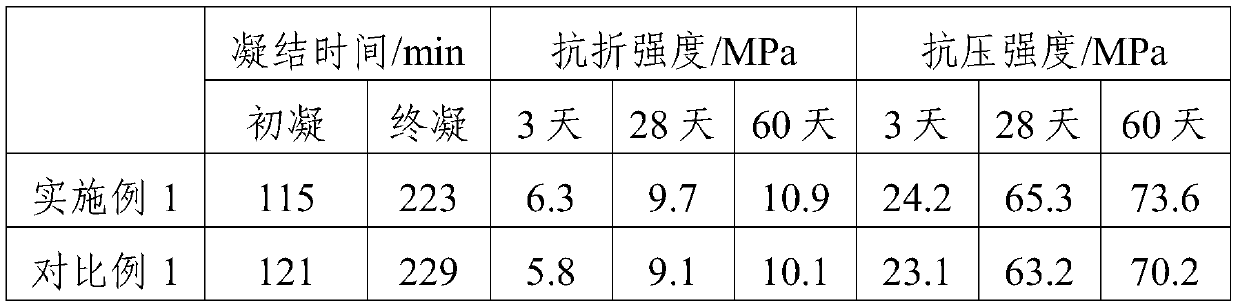

Embodiment 1

[0028] Cement raw materials:

[0029] 100 parts of Portland cement clinker, 11 parts of dihydrate gypsum, 80 parts of yellow phosphorus slag powder, 20 parts of nickel slag powder, 15 parts of zeolite powder, 5 parts of rectorite powder, 8 parts of hydrotalcite powder, 1 part of sucrose, hydrogen Magnesium oxide 1 part.

[0030] Portland cement clinker has a specific surface area of 390m 2 / kg; the chemical composition and mass percentage of Portland cement clinker are: calcium oxide 65%, silicon oxide 23%, aluminum oxide 4%, iron oxide 5%, and other components 3%.

[0031] The specific surface area of yellow phosphorus slag powder is 540m 2 / kg; the chemical composition and mass percentage of yellow phosphorus slag are: calcium oxide 45%, silicon dioxide 40%, aluminum oxide 5%, magnesium oxide 1%, and other components 9%.

[0032] The specific surface area of nickel slag powder is 550m 2 / kg; the chemical composition and mass percentage of nickel slag are: calcium o...

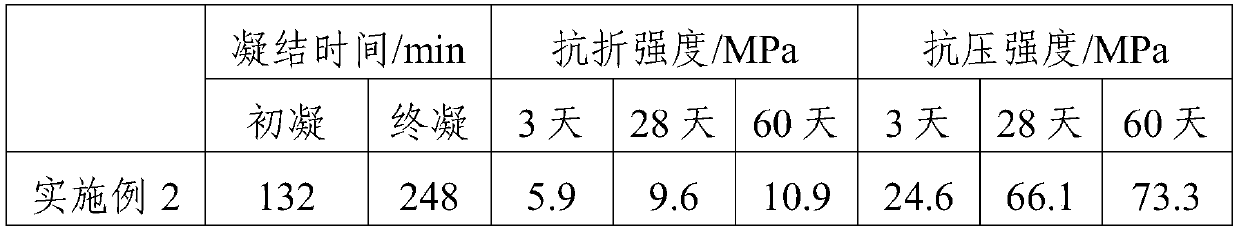

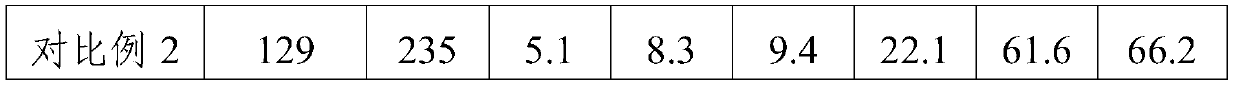

Embodiment 2

[0046] Cement raw materials:

[0047] 100 parts of Portland cement clinker, 9 parts of anhydrite, 100 parts of yellow phosphorus slag powder, 25 parts of nickel slag powder, 13 parts of zeolite powder, 5 parts of rectorite powder, 9 parts of hydrotalcite powder, 0.6 part of sucrose, hydroxide Sodium 0.8 parts.

[0048] Portland cement clinker has a specific surface area of 400m 2 / kg; the chemical composition and mass percentage of Portland cement clinker are: calcium oxide 67%, silicon oxide 21%, aluminum oxide 5%, iron oxide 5%, and other components 2%.

[0049] The specific surface area of yellow phosphorus slag powder is 530m 2 / kg; the chemical composition and mass percentage of yellow phosphorus slag are: calcium oxide 46%, silicon dioxide 42%, aluminum oxide 4%, magnesium oxide 2%, and other components 6%.

[0050] The specific surface area of nickel slag powder is 560m 2 / kg; the chemical composition and mass percentage of nickel slag are: calcium oxide 15%, ...

Embodiment 3

[0065] Cement raw materials:

[0066] 100 parts of Portland cement clinker, 15 parts of dihydrate gypsum, 110 parts of yellow phosphorus slag powder, 10 parts of nickel slag powder, 15 parts of zeolite powder, 4 parts of rectorite powder, 10 parts of hydrotalcite powder, 0.8 parts of sucrose, hydrogen 0.8 parts of magnesium oxide.

[0067] Portland cement clinker has a specific surface area of 420m 2 / kg; the chemical composition and mass percentage of Portland cement clinker are: calcium oxide 67%, silicon oxide 22%, aluminum oxide 4%, iron oxide 6%, and other components 1%.

[0068] The specific surface area of yellow phosphorus slag powder is 510m 2 / kg; the chemical composition and mass percentage of yellow phosphorus slag are: calcium oxide 47%, silicon dioxide 41%, aluminum oxide 5%, magnesium oxide 1%, and other components 6%.

[0069] The specific surface area of nickel slag powder is 500m 2 / kg; the chemical composition and mass percentage of nickel slag are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com