Modified planted forest timber and preparation method thereof

A wood modification technology, applied in the direction of humidity control wood, wood processing equipment, manufacturing tools, etc., can solve the problems of difficult to guarantee product quality stability, decline in wood physical and mechanical properties, limit the application range of carbonized wood, etc., and achieve dimensional stability High performance, high mechanical properties, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Preparation of impregnation solution stock solution

[0054] 1) Prepare the main agent of impregnating liquid

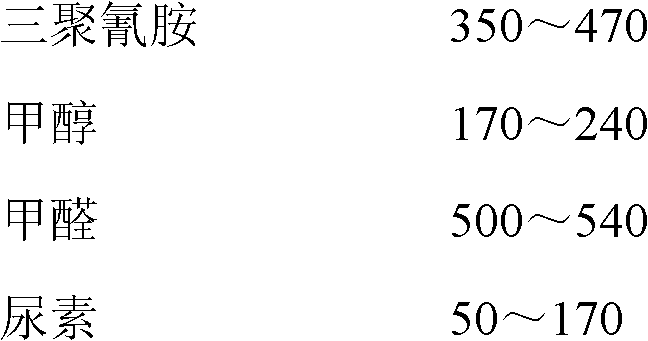

[0055] A) Prepare the raw materials according to the following proportions by weight

[0056] Melamine 350g

[0057] Methanol 220g

[0058] Formaldehyde 520g

[0059] Urea 170g

[0060] Wherein: the mass percentage concentration of formaldehyde is 37%~40%; The mass percentage concentration of methanol is 99.5%;

[0061] B) adding melamine and formaldehyde into the reactor, stirring evenly, adding a sodium hydroxide solution with a concentration of 20% by mass, and adjusting the pH value of the mixed solution of melamine and formaldehyde to 9.2;

[0062] C) heating, raising the temperature of the reactor and keeping it at 80°C, and reacting at this temperature for 40 minutes to obtain a reaction solution;

[0063] D) reduce the temperature of the reaction solution in the reactor and keep it at 70° C., then add a sodium hydroxide solution with a mass pe...

Embodiment 2

[0085] 1. Preparation of impregnation solution stock solution

[0086] 1) Prepare the main agent of impregnating liquid

[0087] A) Prepare the raw materials according to the following proportions by weight

[0088] Melamine 470g

[0089] Methanol 170g

[0090] Formaldehyde 540g

[0091] Urea 50g

[0092] Wherein: the mass percentage concentration of formaldehyde is 37%~40%; The mass percentage concentration of methanol is 99.5%;

[0093] B) Adding melamine and formaldehyde into the reaction kettle, stirring evenly, adding a sodium hydroxide solution with a mass percent concentration of 20%, adjusting the pH value of the mixed solution of melamine and formaldehyde to 9.0;

[0094] C) heating, raising the temperature of the reactor and keeping it at 75°C, and reacting at this temperature for 50 minutes to obtain a reaction solution;

[0095] D) reduce the temperature of the reaction solution in the reactor and keep it at 65°C, then add a sodium hydroxide solution with a c...

Embodiment 3

[0117] 1. Preparation of impregnation solution stock solution

[0118] 1) Prepare the main agent of impregnating liquid

[0119] A) Prepare the raw materials according to the following proportions by weight

[0120] Melamine 400g

[0121] Methanol 240g

[0122] Formaldehyde 500g

[0123] Urea 120g

[0124] Wherein: the mass percentage concentration of formaldehyde is 37%~40%; The mass percentage concentration of methanol is 99.5%;

[0125] B) adding melamine and formaldehyde into the reaction kettle, stirring evenly, adding a sodium hydroxide solution with a mass percentage concentration of 20%, and adjusting the pH value of the mixed solution of melamine and formaldehyde to 9.5;

[0126] C) heating, raising the temperature of the reactor and keeping it at 82° C., reacting at this temperature for 30 minutes to obtain a reaction solution;

[0127] D) After reducing the temperature of the reaction solution in the reactor and keeping it at 75° C., adding a sodium hydroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com