Geopolymer-like cement and preparation method thereof

A geopolymer and cement technology, which is applied to the field of geopolymer-like cement and its preparation, can solve the problems of difficulty in the promotion and application of geopolymers in a large area, no uniform standard for addition amount, and complicated process, so as to widen the source of raw materials and the reaction The effect of strong resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

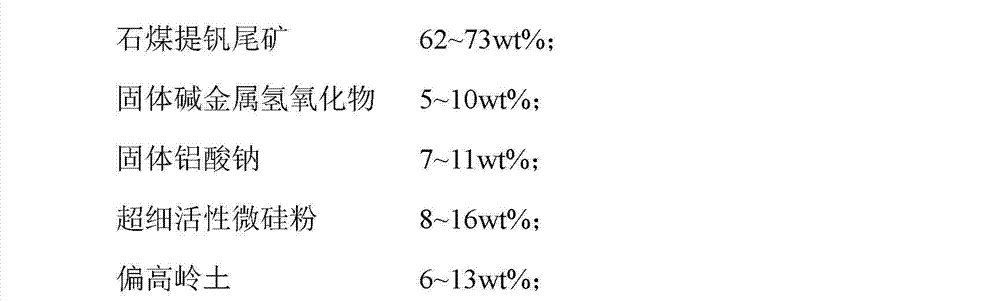

[0024] A type of geopolymer cement and a preparation method thereof. The components and content of geopolymer cement are:

[0025] Vanadium extraction tailings from stone coal 62-68wt%;

[0026] Solid sodium hydroxide 5-7wt%;

[0027] Solid sodium aluminate 9~11wt%;

[0028] 8-12wt% ultrafine active silica fume;

[0029] Metakaolin 6-9wt%;

[0030] According to the above-mentioned components and their contents, the preparation steps of this type of geopolymer cement are:

[0031] In the first step, solid sodium hydroxide is added to the tailings of vanadium extraction from stone coal, mechanically stirred for 5 to 10 minutes, and then placed in a ball mill for dry ball milling for 10 to 15 minutes to obtain a ball mill;

[0032] The second step is to put the ball abrasive into the muffle furnace for calcination at a temperature of 300-400°C; keep the temperature for 3-4 hours to obtain the calcined material;

[0033] The third step is to cool the calcined material at roo...

Embodiment 2

[0038] A type of geopolymer cement and a preparation method thereof. The components and content of geopolymer cement are:

[0039] Vanadium extraction tailings from stone coal 68~73wt%;

[0040] Solid potassium hydroxide 5-7wt%;

[0041] Solid sodium aluminate 7-9wt%;

[0042] 8-12wt% ultrafine active silica fume;

[0043] Metakaolin 6-9wt%;

[0044] According to the above-mentioned components and their contents, the preparation steps of this type of geopolymer cement are:

[0045] In the first step, solid potassium hydroxide is added to the tailings of vanadium extraction from stone coal, mechanically stirred for 5-10 minutes, and then placed in a ball mill for dry ball milling for 10-15 minutes to obtain a ball mill;

[0046] The second step is to put the ball abrasive into the muffle furnace for calcination at a temperature of 400-500°C; keep the temperature for 3-4 hours to obtain the calcined material;

[0047]The third step is to cool the calcined material at room ...

Embodiment 3

[0052] A type of geopolymer cement and a preparation method thereof. The components and content of geopolymer cement are:

[0053] Vanadium extraction tailings from stone coal 62-68wt%;

[0054] The mixture of solid sodium hydroxide and solid potassium hydroxide 5-7wt%;

[0055] Solid sodium aluminate 7-9wt%;

[0056] Ultrafine active micro-silica powder 12-16wt%;

[0057] Metakaolin 6-9wt%;

[0058] According to the above-mentioned components and their contents, the preparation steps of this type of geopolymer cement are:

[0059] The first step, adding a mixture of solid sodium hydroxide and solid potassium hydroxide to the tailings of vanadium extraction from stone coal, mechanically stirring for 5 to 10 minutes, and then placing it in a ball mill for dry ball milling for 10 to 15 minutes to obtain a ball mill;

[0060] The second step is to put the ball abrasive into the muffle furnace for calcination at a temperature of 500-600°C; keep the temperature for 2-3 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com