Sulfur fixation ash-fly ash compounded environment-friendly void grouting material as well as preparation method and application thereof

A technology of sulfur-fixing ash and grouting material, which is used in bridge reinforcement, erection/assembly of bridges, bridges, etc., to achieve the effects of excellent shrinkage resistance, improved cost performance and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In yet another specific embodiment of the present invention, a method for preparing an environment-friendly hollow grouting material compounded with sulfur-fixed ash-fly ash is provided, and the steps are as follows:

[0046] (1) Take the sulfur-fixing ash and fly ash according to the amount, wherein the sulfur-fixing ash and fly ash are sieved; the sulfur-fixing slag is crushed, ground, and sieved; Coal ash and crushed sulfur-fixing slag are heated for anaerobic high-temperature activation; then cooled to room temperature and mixed evenly to obtain component A.

[0047] (2) Weigh the early strength agent, water reducer, defoamer, expansion agent and water according to the amount, and stir them evenly to prepare component B of the auxiliary agent.

[0048] (3) Weigh water glass, slaked lime, caustic soda, ordinary Portland cement and plaster of paris, and mechanically stir them evenly to prepare component C of the curing agent.

[0049] (4) During construction, after m...

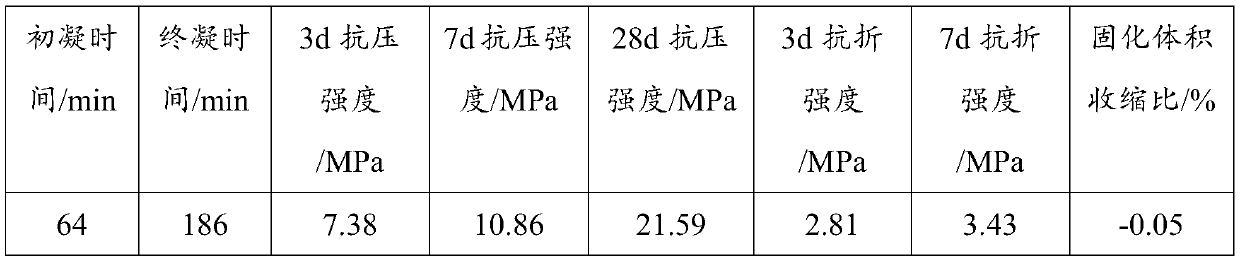

Embodiment 1

[0058] A preparation method of a sulfur-fixed ash-fly ash composite environment-friendly hollow-out grouting material is as follows:

[0059] (1) Weigh 30g of sulfur-fixed ash and 40g of fly ash, and sieve them through 1mm respectively, and keep the sieved samples. Weigh 40g of sulfur-fixing slag, preliminarily crush the sulfur-fixing slag, and then use a ball mill to grind for 40 minutes, use a 2mm sieve to sieve, and take a specific surface area of 260-480m 2 / kg of sulfur-fixing slag powder.

[0060] (2) The above samples were heated in an oxygen-free high-temperature furnace at 500° C. for 3 hours to perform high-temperature activation. Then cool to room temperature, stir and mix evenly to obtain component A.

[0061] (3) Weigh 1g of early strength agent calcium chloride, 2.5g of polycyclic aromatic salt of water reducer, 1.0g of defoamer polyether, 0.02g of expansion agent, aluminum powder and 25g of water, mechanically stir evenly, and prepare Auxiliary component B ...

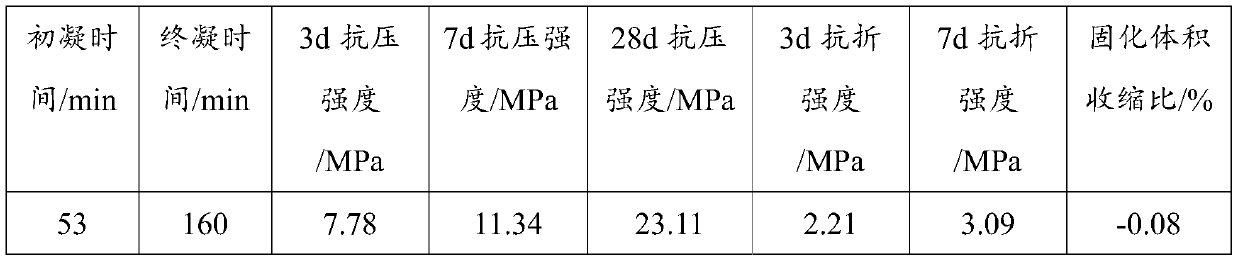

Embodiment 2

[0067] A preparation method of a sulfur-fixed ash-fly ash composite environment-friendly hollow-out grouting material is as follows:

[0068] (1) Weigh 60g of sulfur-fixed ash and 30g of fly ash, sieve them through 1mm respectively, and keep the sieved samples. Weigh 60g of the sulfur-fixing slag, preliminarily crush the sulfur-fixing slag, and then use a ball mill to grind it for 40 minutes, and use a 2mm sieve to sieve it to obtain a specific surface area of 260-480m 2 / kg of sulfur-fixing slag powder.

[0069] (2) The above samples were heated in an oxygen-free high-temperature furnace at 500° C. for 3 hours to perform high-temperature activation. Then cool to room temperature, stir and mix evenly to obtain component A.

[0070] (3) Weigh 2g of early strength agent sodium chloride, 2g of water reducing agent polycarboxylic acid, 3.0g of defoaming agent organosilicon, 0.01g of expansion agent calcium sulfoaluminate and 40g of water, stir mechanically to obtain Auxiliary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com