Preparation method of microporous PMI (polymethacrylimide) foam and PMI foam prepared by method

A microporous and foam technology, which is applied in the field of preparation of high-performance polymethacrylimide microporous materials, can solve the problems of reducing material strength, foam performance degradation, easy settlement, etc., and achieves good heat resistance and foaming High efficiency and narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

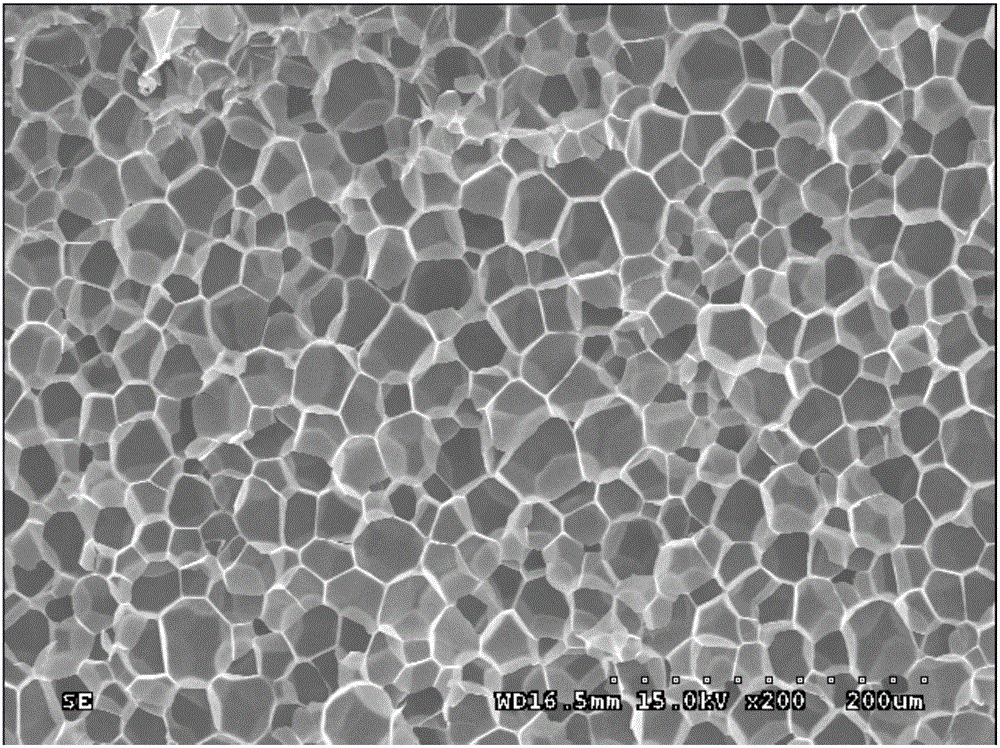

[0040] 44 parts by weight of methacrylic acid, 43 parts by weight of methacrylonitrile, 5 parts by weight of the third monomer (acrylamide), 0.5 parts by weight of initiator (dibenzoyl peroxide), blowing agent (C 1 ~C 7Fatty alcohol) 7 parts by weight, cross-linking agent (magnesium methacrylate) 0.1 parts by weight, as raw materials and mixed and stirred to obtain a uniform mixed liquid, and then pre-polymerized at 42 ° C for 55 hours in a closed mold to obtain a transparent pre-polymerized block , and then post-polymerize at 80°C for 70h; then place the pre-polymerized block in an oven with panels that can emit ultrasonic waves up and down, turn on the ultrasonic wave at 140°C (ultrasonic power is 90%), and the ultrasonic wave promotes nucleation for 1h; then Raise the temperature to 218°C, stop the ultrasound, and continue foaming for 2 hours to obtain a foam with excellent performance and uniform pore size distribution (such as figure 1 shown). Foam pore size is 20μm, de...

Embodiment 2

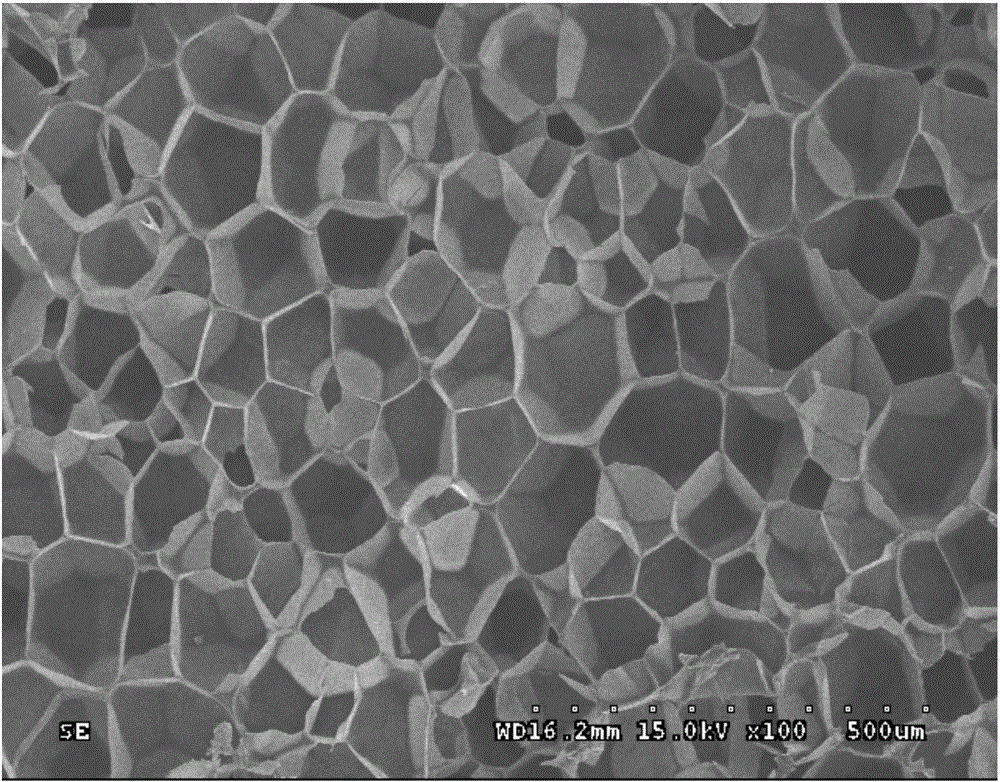

[0042] 48.3 parts by weight of methacrylic acid, 40 parts by weight of methacrylonitrile, 4 parts by weight of the third monomer (acrylamide), 0.6 parts by weight of initiator (lauroyl peroxide), foaming agent (formamide page: 5) 7 parts by weight, 0.1 parts by weight of crosslinking agent (magnesium methacrylate), as raw materials and mixed and stirred to obtain a uniform mixed liquid, then pre-polymerized at 40°C for 50h in a closed mold to obtain a transparent pre-polymerized plate body, and then in 90 After polymerization at ℃ for 70h; then place the pre-polymerized block in an oven with panels that can emit ultrasonic waves up and down, turn on the ultrasonic wave at 140°C (ultrasonic power is 50%), and the ultrasonic wave promotes nucleation for 2h; then raise the temperature At 218°C, stop the ultrasound, continue to foam for 2 hours, and obtain a foam with excellent performance and uniform pore size distribution (such as figure 2 shown). Foam pore size is 100μm, dens...

Embodiment 3

[0044] 52.3 parts by weight of methacrylic acid, 41 parts by weight of methacrylonitrile, 0 parts by weight of the third monomer (methacrylamide), 0.5 parts by weight of initiator (azobisisobutyronitrile), foaming agent (methylurea ) 6 parts by weight, crosslinking agent (magnesia) 0.2 parts by weight, as raw materials and mixed and stirred to obtain a uniform mixed liquid, and then pre-polymerized at 42°C for 55h in a closed mold to obtain a transparent pre-polymerized plate body, and then at 90°C Post-polymerization for 65 hours; then place the pre-polymerized plate body in an oven, with panels that can emit ultrasonic waves up and down, turn on the ultrasonic wave (ultrasonic power is 90%) at 150 ° C, and the ultrasonic wave promotes nucleation for 2 hours; then raise the temperature to At 210°C, stop ultrasonication and continue foaming for 2 hours to obtain a foam with excellent performance and uniform pore size distribution. Foam pore size is 10μm, density 75kg / m 3 , an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com