Method for controlling low-melting-point inclusion in high-strength low-alloy steel

A technology of high-strength low-alloy and low-alloy steel, which is applied in the field of steelmaking and refining, and can solve the problems of reduced HIC resistance, high strength and low performance, and affecting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

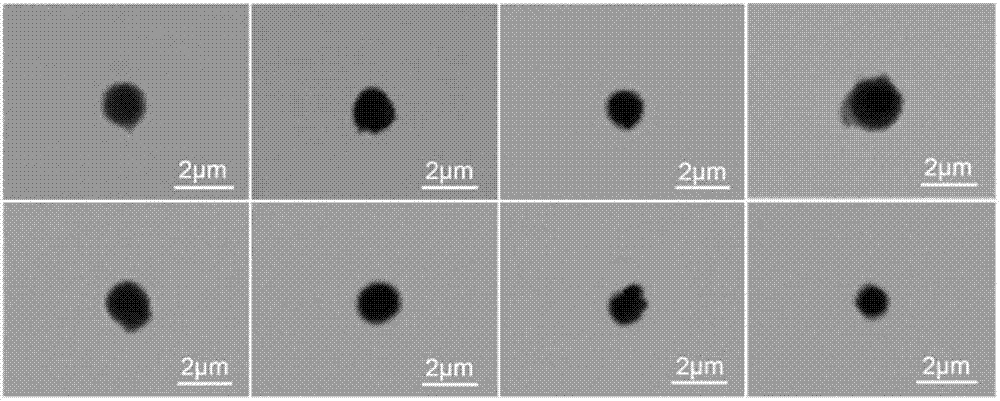

Image

Examples

specific Embodiment 1

[0033] Step 1: Tap steel from a 210-ton oxygen top-bottom combined blowing converter to the ladle. During the tapping process, add 1100kg of aluminum and iron, of which the aluminum content in the aluminum-iron alloy is 40wt%, 900kg of lime, and 240kg of fluorite. It is completed at 1 / 4; the aluminum content in the molten steel is 0.04wt% after tapping.

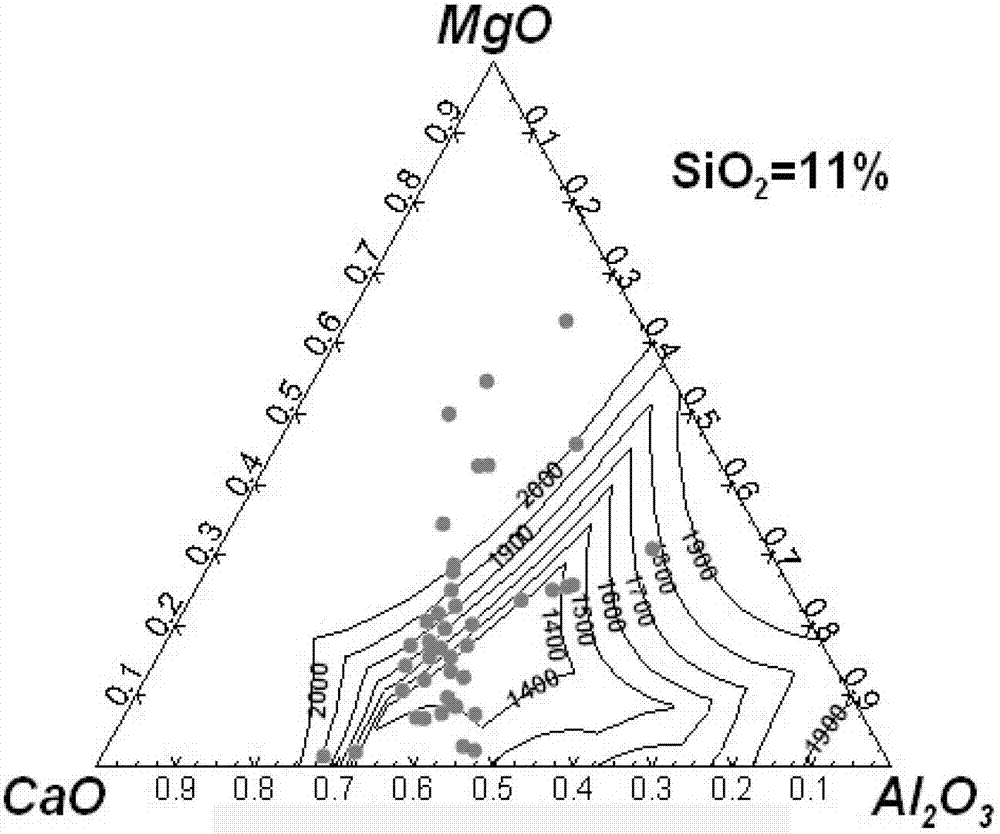

[0034] Step 2. The basicity of slag in the LF refining process (i.e. CaO / SiO 2 Ratio) is 3.5-5; the composition of slag at the end of slagging (taking the average value of eight heats in this embodiment) is: CaO: 54.79wt%; SiO 2 : 12.31wt%; Al 2 o 3 : 21.37wt%; MgO: 7.82wt%; T.Fe+MnO: 0.52wt%.

[0035] Step 3: After the slagging is completed, carry out desulfurization by blowing Ar gas at the bottom of the ladle with strong agitation, the flow rate of Ar is 1200 Nl / min, and the time of bottom blowing is 15 minutes. At the end of LF refining, the sulfur content of molten steel in eight heats was between 0.0006% and 0.0018%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com