Method for preparing fuel from light bio-oil

A bio-oil, light-weight technology, applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of poor selectivity, dispersion of target products, low conversion rate of light bio-oil, etc., to reduce hydrogen consumption and simple operation , the effect of not easy to coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

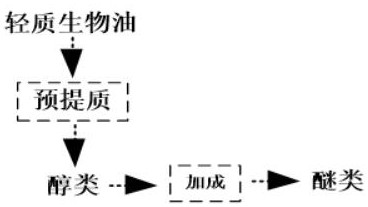

[0031] The method for preparing fuel from bio-oil of the present invention, such as figure 1 As shown, the specific steps are as follows:

[0032] Step 1: pre-upgrade the light bio-oil and turn it into alcohols. Specifically, the following operations can be used:

[0033] The light bio-oil was placed in a catalytic upgrading system for hydrocatalytic treatment. The reaction pressure was 6 MPa, the reaction temperature was 140 °C, the reaction time was 4 h, and the catalyst was Raney Ni. In this step, the mass ratio of light bio-oil to catalyst is 20:1.

[0034] After the reaction, the temperature of the system is lowered to normal temperature, and the reactants are taken out and filtered to obtain pre-upgraded bio-oil rich in alcohols.

[0035] Step 2: the alcohol substance that becomes becomes ether substance. Specifically, the following operations can be used:

[0036] Put the pre-upgraded oil in the catalytic upgrading system again, and add isobutene and catalyst Amber...

Embodiment 2

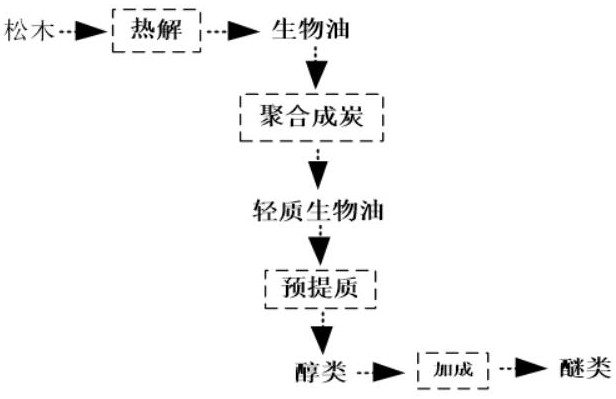

[0039] The method for preparing fuel from bio-oil of the present invention, see figure 2 As shown, the specific steps are as follows:

[0040] Step 1: Prepare light bio-oil by pyrolysis using pine wood raw material.

[0041] Step 2: Put the collected light bio-oil in the catalytic upgrading system for hydrocatalytic treatment, the reaction pressure is 7 MPa, the reaction temperature is 120 °C, the reaction time is 6 h, and the catalyst is Raney Ni. The mass ratio of light bio-oil to catalyst is 15:1. After the reaction, the temperature of the system is lowered to normal temperature, and the reactants are taken out and filtered to obtain pre-upgraded bio-oil rich in alcohols.

[0042] Step 3: Place the pre-upgraded oil in the catalytic upgrading system again, and add octene and catalyst Amberlyst-15 at the same time to carry out addition reaction. The reaction temperature is 80°C, the reaction time is 3 hours, and after the reaction of the pre-upgraded oil and octene at a m...

Embodiment 3

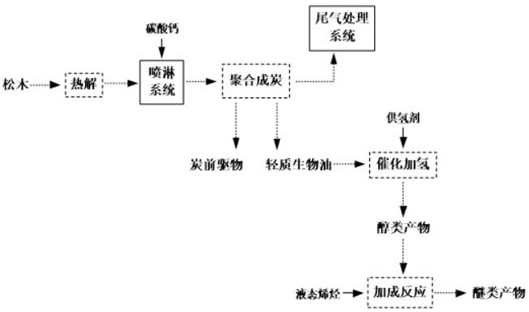

[0044] The method for preparing fuel from bio-oil of the present invention, see image 3 As shown, the specific steps are as follows:

[0045] Step 1: Prepare light bio-oil by using pine raw material, the steps are as follows:

[0046] The pine wood raw material was dried for 12 hours in a blast drying oven at a temperature of 105°C, and the dried pine wood was pyrolyzed in a vertical furnace at a temperature of 450-550°C. In this example, the pyrolysis temperature Using 500°C, N 2 The flow rate is 0.45L / min, and the holding time is 1.5 h. The bio-oil produced during the pyrolysis process is passed through the device first image 3 After the middle spray system removes the heavy components, the light bio-oil is collected through the condensation system, and after the collection is completed, it is purified through the tail gas treatment system.

[0047] Step 2: Put the collected light bio-oil in the catalytic upgrading system for hydrocatalytic treatment, the reaction pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com