Hydrogenation method of C9 < + > fraction for pyrolysis gasoline

A pyrolysis gasoline and distillate technology, which is applied in the field of hydrogenation of pyrolysis gasoline, can solve the problems of poor hydrogenation effect, achieve the effects of reducing energy consumption, reducing difficulty, and avoiding polymerization reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

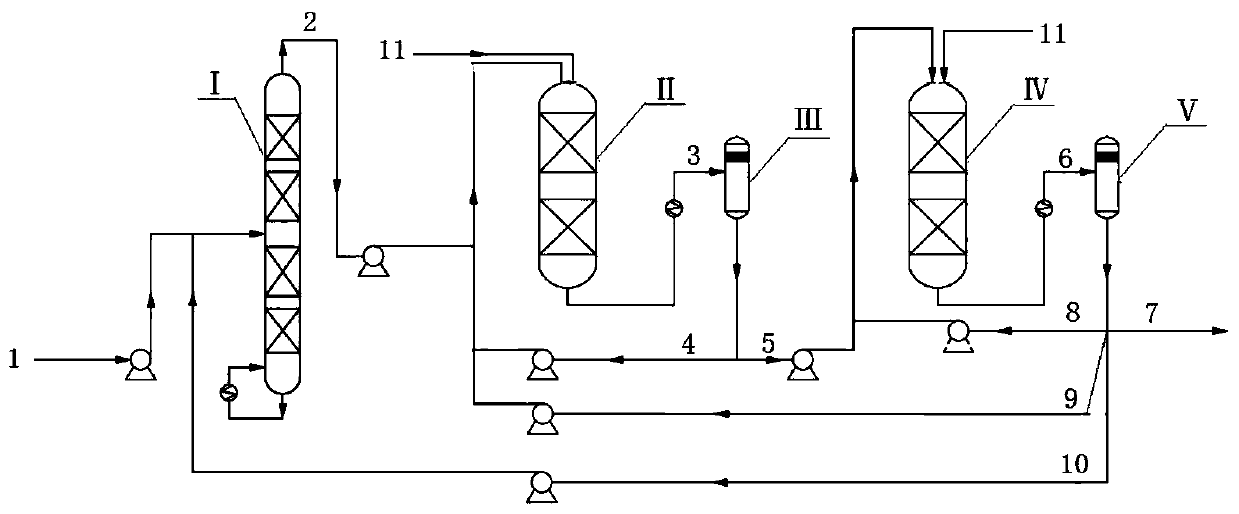

Method used

Image

Examples

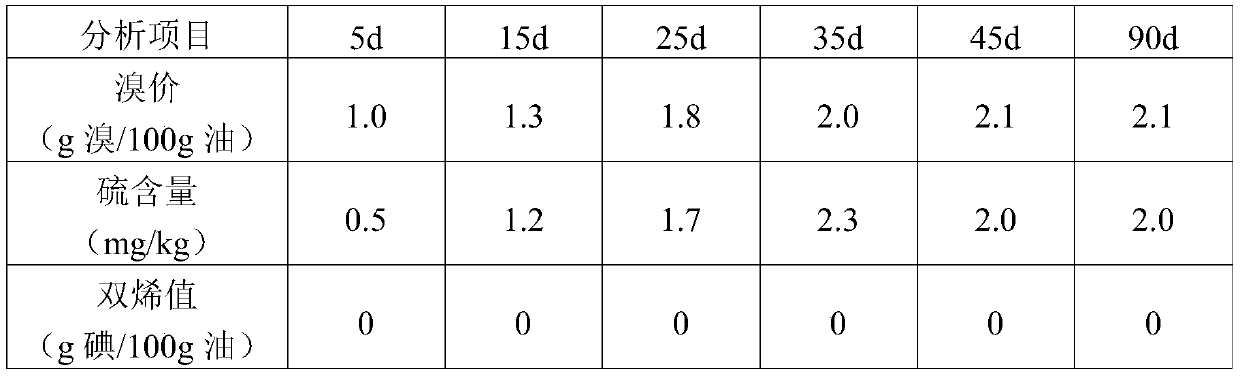

Embodiment 1

[0056] Step A. Preparation of the first catalyst

[0057] a) Al 2 O 3 / TiO 2 Preparation of composite oxide carrier

[0058] Take the specific surface area as 160m 2 / g, the pore volume is 0.58ml / g, the most probable pore size is 170g of clover alumina, placed in 106ml of tetraethyl titanate in cyclohexane (the mass concentration of tetraethyl titanate is 0.808ml / g), stirred for 15 minutes and dried at 120°C for 6 hours , Then calcined at 600°C for 4 hours to obtain Al 2 O 3 / TiO 2 Composite oxide support (named Z1). Among them, TiO 2 The content is 15.0%.

[0059] b) Load of active ingredients

[0060] Take 100g of the Z1 prepared in step a), and place it in 50ml of nickel nitrate aqueous solution (the mass concentration of nickel nitrate is 24g / 100ml in terms of nickel atoms) and immerse it for 2h. After dehydration treatment with compressed air for 20min, at 110 Drying at °C for 8 hours, and then calcining at 550 °C for 5 hours to prepare the first catalyst precursor (named NZ1)...

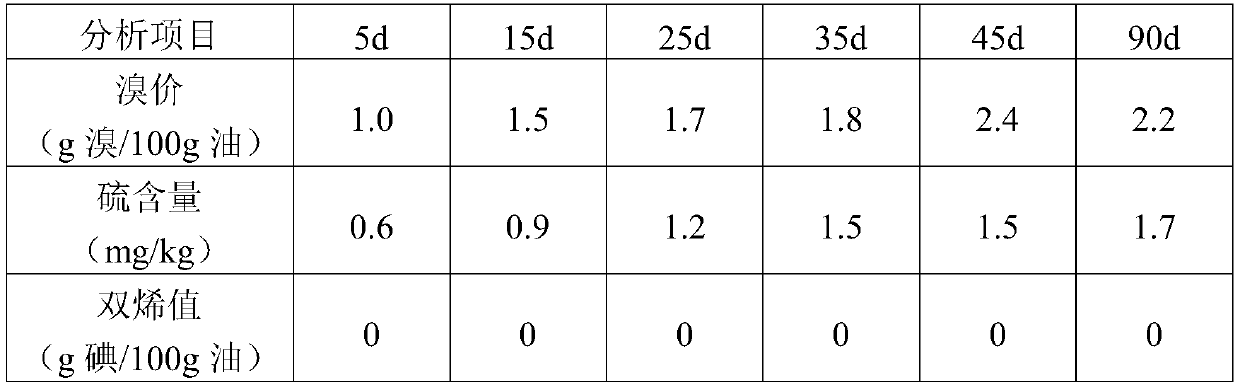

Embodiment 2

[0086] Step A. Preparation of the first catalyst

[0087] a) Al 2 O 3 / TiO 2 Preparation of composite oxide carrier

[0088] Take the specific surface area as 160m 2 / g, the pore volume is 0.58ml / g, the most probable pore size is 170g of clover alumina, placed in 100ml of tetraethyl titanate in cyclohexane (the mass concentration of tetraethyl titanate is 0.490ml / g), stirred for 15 minutes and dried at 120°C for 6 hours , Then calcined at 600°C for 4 hours to obtain Al 2 O 3 / TiO 2 Composite oxide support (named Z3). Among them, TiO 2 The content is 24.3%.

[0089] b) Load of active ingredients

[0090] Take 100g of the Z2 prepared in step a), and place it in 50ml of nickel nitrate aqueous solution (the mass concentration of nickel nitrate is 20g / 100ml in terms of nickel atoms) and soak for 2h. After dehydration treatment with compressed air for 20min, Drying at °C for 8 hours, and then calcining at 550 °C for 5 hours to prepare the first catalyst precursor (named NZ3).

[0091] Tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com