Preparation method of lipophilic hyperbranched molecule modified nanofluid

A nanofluid, lipophilic technology, applied in the field of heat transfer, can solve the problems of the influence of the heat transfer capacity of the nanofluid, the stability of the nanofluid is difficult to be guaranteed, etc., and achieve the effect of easy popularization and application, not easy to aggregate, and prolong life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the lipophilic hyperbranched molecular modified nanofluid of the present embodiment is as follows:

[0035] (1) Add 10 g of hexadecyl chloride to 40 mL of chloroform, under nitrogen protection, dissolve 2 g of PEI (number average molecular weight distribution 1000-36000) in chloroform and add to the above solution, then add 5 g of triethyl amine, the mixture was vigorously stirred at 0 °C for 3 h, then reacted at 25 °C for 24 h, and finally reacted at 70 °C for 2 h to obtain a crude product; then, the crude product was cooled to room temperature, filtered to remove waste residue, and stirred in 400 mL of acetone 1h, discard the upper layer of acetone, repeat washing twice, 35 ℃ rotary evaporation and vacuum drying to obtain HPEI-C16;

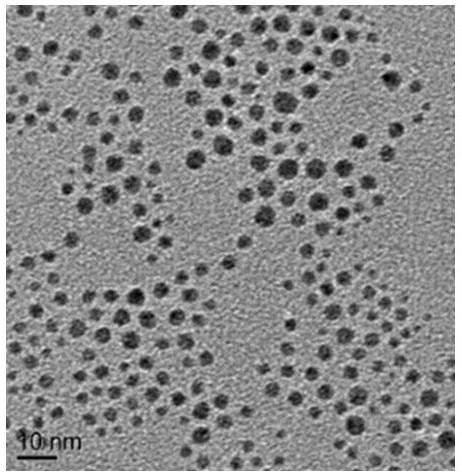

[0036] (2) Add 0.4 g tetra-n-octylammonium bromide and 0.2 g potassium chloropalladate to 120 mL toluene, and react for 1 h. Take the organic phase, add 0.2 g HPEI-C16, add 20 mL NaBH dropwise 4 Aqueous solutio...

Embodiment 2

[0040] The preparation method of the lipophilic hyperbranched molecular modified nanofluid of the present embodiment is as follows:

[0041] (1) Add 0.3 g tetra-n-octylammonium bromide and 0.1 g potassium chloropalladate to 120 mL toluene, and react for 1 h. Take the organic phase, add 0.2 g of HPEI-C16 obtained in Example 1, add 20 mL of NaBH dropwise 4 Aqueous solution (0.1 g / 10 mL water), stirring vigorously for 12 h, standing still to take the organic layer; rotary evaporation at 45 ℃ to get the crude product, washing with absolute ethanol 3 times, drying in vacuum overnight at 25 ℃ to obtain lipophilic hyperbranched molecular modification nanoparticles;

[0042] (2) The nanoparticles obtained in step (1) were weighed, added to decahydronaphthalene for ultrasonic dispersion for 1 h, and a lipophilic hyperbranched molecule-modified nanofluid with a nanoparticle content of 0.01% to 0.5% was obtained.

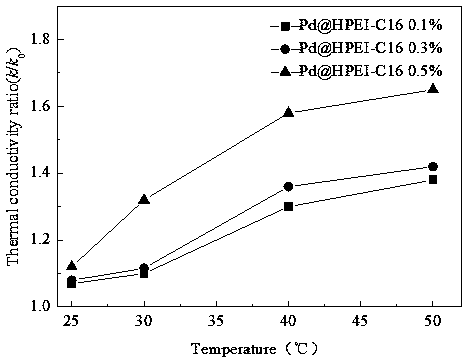

[0043] The palladium nanofluid can exist stably for more than one month...

Embodiment 3

[0045] The preparation method of the lipophilic hyperbranched molecular modified nanofluid of the present embodiment is as follows:

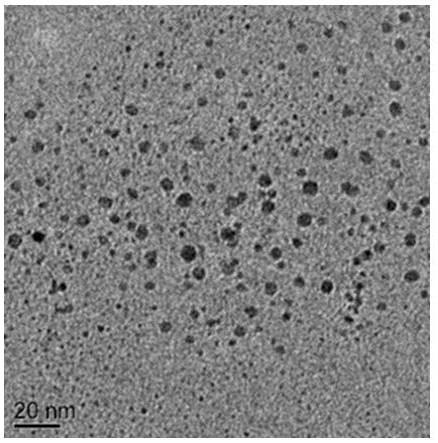

[0046] (1) Add 0.3 g tetra-n-octylammonium bromide and 0.4 g potassium chloropalladate to 120 mL toluene, and react for 1 h. Take the organic phase, add 0.2 g of HPEI-C16 obtained in Example 1, add 20 mL of NaBH dropwise 4 Aqueous solution (0.1 g / 10 mL water), stirring vigorously for 12 h, standing still to take the organic layer; rotary evaporation at 45 ℃ to get the crude product, washing with absolute ethanol 3 times, drying in vacuum overnight at 25 ℃ to obtain lipophilic hyperbranched molecular modification nanoparticles.

[0047] (2) The nanoparticles obtained in step (1) were weighed, added to decahydronaphthalene for ultrasonic dispersion for 1 h, and a lipophilic hyperbranched molecule-modified nanofluid with a nanoparticle content of 0.01% to 0.3% was obtained.

[0048] The palladium nanofluid can exist stably for more than 15 days, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com