Polycarboxylic acid polymer, preparation method and application thereof

A polymer and polycarboxylic acid technology, applied in the field of building materials preparation, can solve the problems of reduced grinding aid performance, low conversion rate, high viscosity of the system, etc., and achieve the effects of reducing surface energy, increasing content, and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

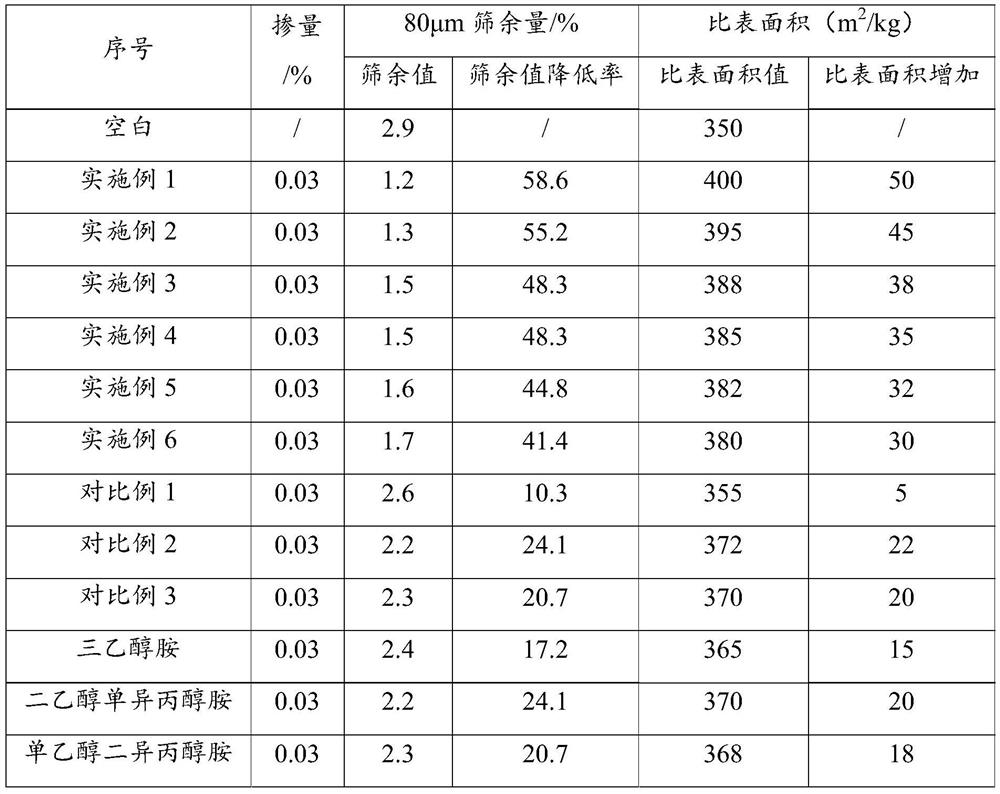

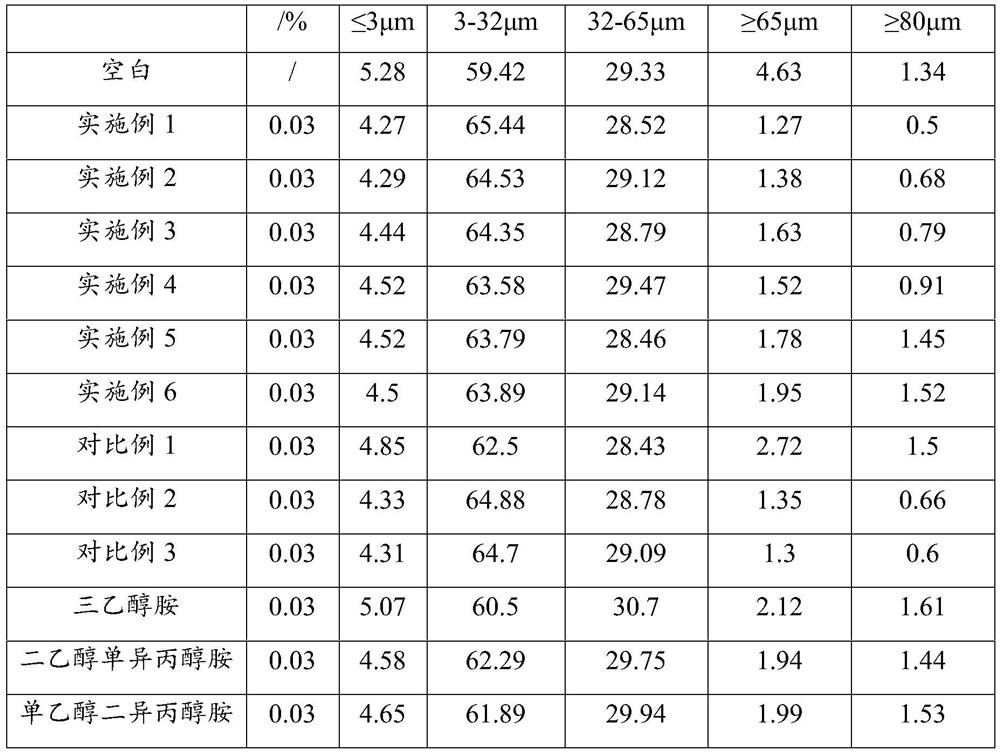

Examples

Embodiment 1

[0056] The present embodiment provides a kind of preparation method of polycarboxylic acid polymer, comprises the following steps,

[0057] (1) The preparation method of esterification monomer comprises the steps:

[0058] Add 18kg of acrylic acid and 17.7kg of monoethanol diisopropanolamine into the reactor, fill it with nitrogen while stirring, raise the temperature to 80°C, add 0.2kg of hydroquinone, stir for 20min, then add 0.15kg of concentrated sulfuric acid, and react at constant temperature 4h, after stopping the reaction, the unreacted acrylic acid was distilled off under reduced pressure to obtain the esterified monomer.

[0059] (2) Get above-mentioned 100g esterification monomer, 2.36kg acrylic acid and 174g mercaptopropionic acid (chain transfer agent), be mixed with mixed solution B;

[0060] Get 171g ammonium persulfate and 400g water in addition and be mixed with the second initiator solution C;

[0061] 52g L-ascorbic acid as the second reducing agent D.

...

Embodiment 2

[0065] The present embodiment provides a kind of preparation method of polycarboxylic acid polymer, comprises the following steps,

[0066] (1) The preparation method of esterification monomer comprises the steps:

[0067] Add 18kg of acrylic acid and 16.3kg of diethanol monoisopropanolamine into the reaction kettle, fill it with nitrogen while stirring, raise the temperature to 80°C, add 0.2kg of hydroquinone, stir for 20min, then add 0.15kg of concentrated sulfuric acid, and react at constant temperature 4h, after stopping the reaction, the unreacted acrylic acid was distilled off under reduced pressure to obtain the esterified monomer.

[0068] (2) Get above-mentioned 90g esterification monomer, 1.93kg acrylic acid and 174g mercaptopropionic acid (chain transfer agent), be mixed with mixed solution B;

[0069] Get 171g ammonium persulfate and 400g water in addition and be mixed with the second initiator solution C;

[0070] 52gL-ascorbic acid is the second reducing agent ...

Embodiment 3

[0074] The present embodiment provides a kind of preparation method of polycarboxylic acid polymer, comprises the following steps,

[0075] (1) The preparation method of esterification monomer comprises the steps:

[0076] Add 18kg of acrylic acid and 17.7kg of diethanol monoisopropanolamine into the reaction kettle, fill it with nitrogen while stirring, raise the temperature to 80°C, add 0.2kg of hydroquinone, stir for 20min, then add 0.15kg of concentrated sulfuric acid, and react at constant temperature 4h, after stopping the reaction, the unreacted acrylic acid was distilled off under reduced pressure to obtain the esterified monomer.

[0077] (2) Take the above-mentioned 150g esterified monomer, 2.9kg acrylic acid and 226g mercaptopropionic acid (chain transfer agent), and prepare mixed solution B.

[0078] Get 222g ammonium persulfate and 520g water in addition and be mixed with the first initiator solution C;

[0079] 59.8g of sodium bisulfite formaldehyde and 139g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com