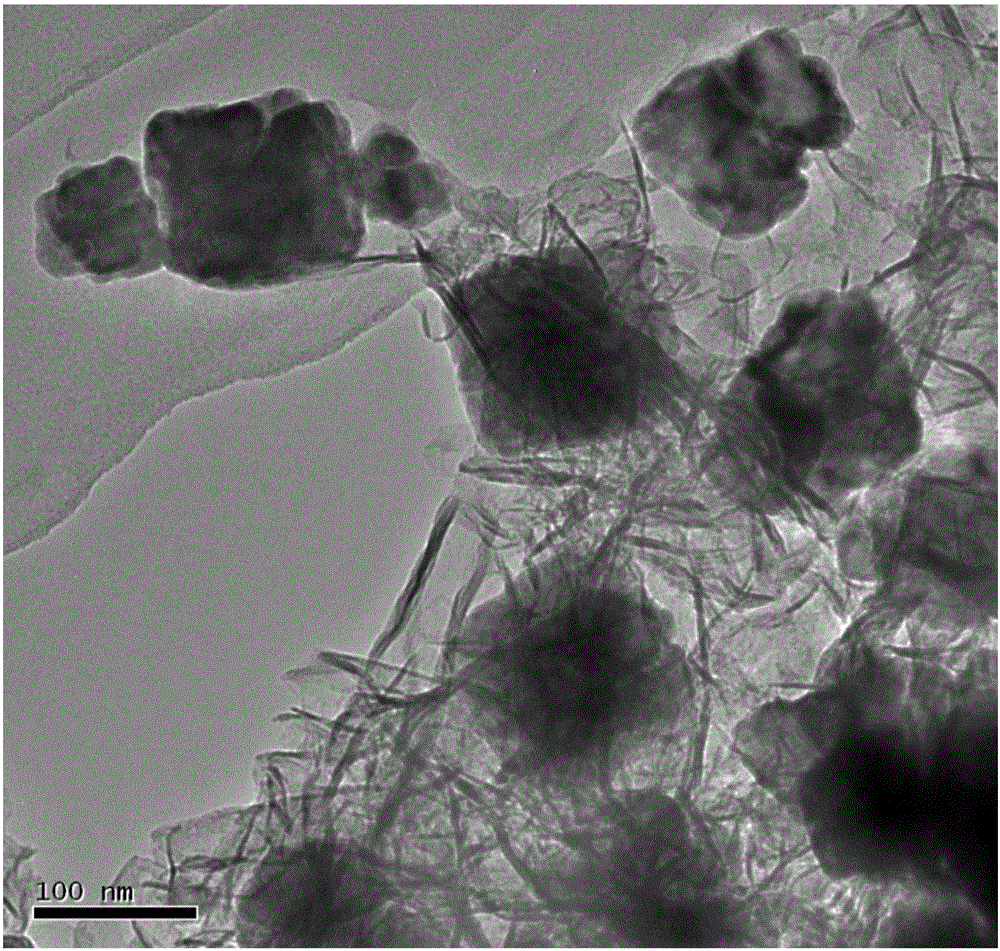

Method for preparing Ni/Fe bi-metal face-centered cubic crystal nano particles

A face-centered cubic and nano-particle technology, applied in the field of nano-materials, can solve problems such as pollution and difficult degradation, and achieve the effects of strong process controllability, difficult polymerization, and uniform dispersion polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

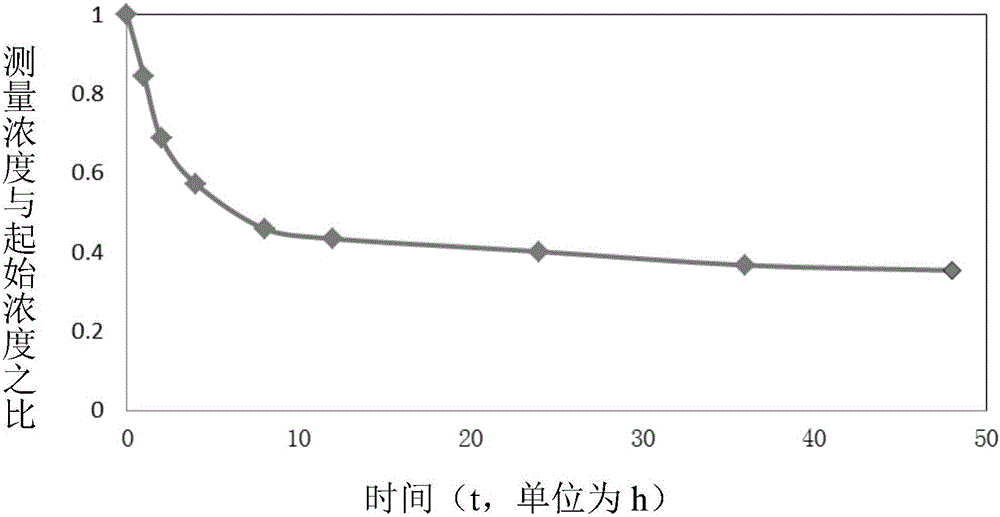

Image

Examples

Embodiment 1

[0025] (1) Dissolve 4g of PVP (K30) in deionized water, mix thoroughly by magnetic stirring, and set the volume to 50ml to obtain a PVP solution with a mass volume concentration of 8%.

[0026] (2) Take 7.5ml of the PVP solution as described in (1) and dissolve it in the mixed solution of deionized water and absolute ethanol, transfer it into a three-necked bottle, and pass nitrogen to remove oxygen for 30 minutes. The total volume of the solution is 50ml, PVP solution is 7.5ml, deionized water is 22.5ml, ethanol is 20ml, and the volume ratio is 3:9:8.

[0027] (3) Weigh 0.417g FeSO 4 ·7H 2 O powder was added to the above solution, and mixed for 20 minutes under the condition of mechanical stirring at a speed of 2000r / min, so that FeSO 4 ·7H 2 O powder is fully dissolved, at this time FeSO 4 ·7H 2 The molar concentration of O is 0.03 mol / L.

[0028] (4) Slowly add NaBH dropwise to the three-necked bottle 4 solution, according to n(Fe 2+ ) and n(BH 4 — ) ratio 1:2, Na...

Embodiment 2

[0033] (1) Dissolve 5g of PVP (K30) in deionized water, mix thoroughly by magnetic stirring, and set the volume to 50ml to obtain a PVP solution with a mass volume concentration of 10%.

[0034] (2) Take 7.5ml of the PVP solution as described in (1) and dissolve it in the mixed solution of deionized water and absolute ethanol, transfer it into a three-necked bottle, and pass nitrogen to remove oxygen for 30 minutes. The total volume of the solution is 50ml, PVP solution is 7.5ml, deionized water is 22.5ml, ethanol is 20ml, and the volume ratio is 3:10:10.

[0035] (3) Weigh 0.417g FeSO 4 ·7H 2 O powder was added to the above solution, and mixed for 15 minutes under the condition of mechanical stirring at a speed of 2000r / min, so that FeSO 4 ·7H 2 O powder is fully dissolved, at this time FeSO 4 ·7H 2 The molar concentration of O is 0.03 mol / L.

[0036] (4) Slowly add NaBH dropwise to the three-necked bottle 4 solution, according to n(Fe 2+ ) and n(BH 4 — ) ratio 1:2,...

Embodiment 3

[0041] (1) Dissolve 5g of PVP (K30) in deionized water, mix thoroughly by magnetic stirring, and set the volume to 50ml to obtain a PVP solution with a mass volume concentration of 10%.

[0042] (2) Take 7.5ml of the PVP solution as described in (1) and dissolve it in the mixed solution of deionized water and absolute ethanol, transfer it into a three-necked bottle, and pass nitrogen to remove oxygen for 30 minutes. The total volume of the solution is 50ml, PVP solution is 7.5ml, deionized water is 22.5ml, ethanol is 20ml, and the volume ratio is 3:9:9.

[0043] (3) Weigh 0.417g FeSO 4 ·7H 2 O powder was added to the above solution, and mixed for 20 minutes under the condition of mechanical stirring at a speed of 2000r / min, so that FeSO 4 ·7H 2 O powder is fully dissolved, at this time FeSO 4 ·7H 2 The molar concentration of O is 0.03 mol / L.

[0044] (4) Slowly add NaBH dropwise to the three-necked bottle 4 solution, according to n(Fe 2+ ) and n(BH 4 — ) ratio 1:2, N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com