N-acrylyl amino acid polymerizable emulsifier and preparation method thereof

A technology of acryloyl amino acid and polymeric emulsifier, which is applied in the preparation of carboxylic acid amide, chemical instruments and methods, and the preparation of organic compounds, etc. It can solve the problems of high raw material prices, high product prices, poor emulsification and dispersion performance, etc., and achieve The effect of high-efficiency polymerization performance, excellent emulsification performance, and excellent polymerization stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

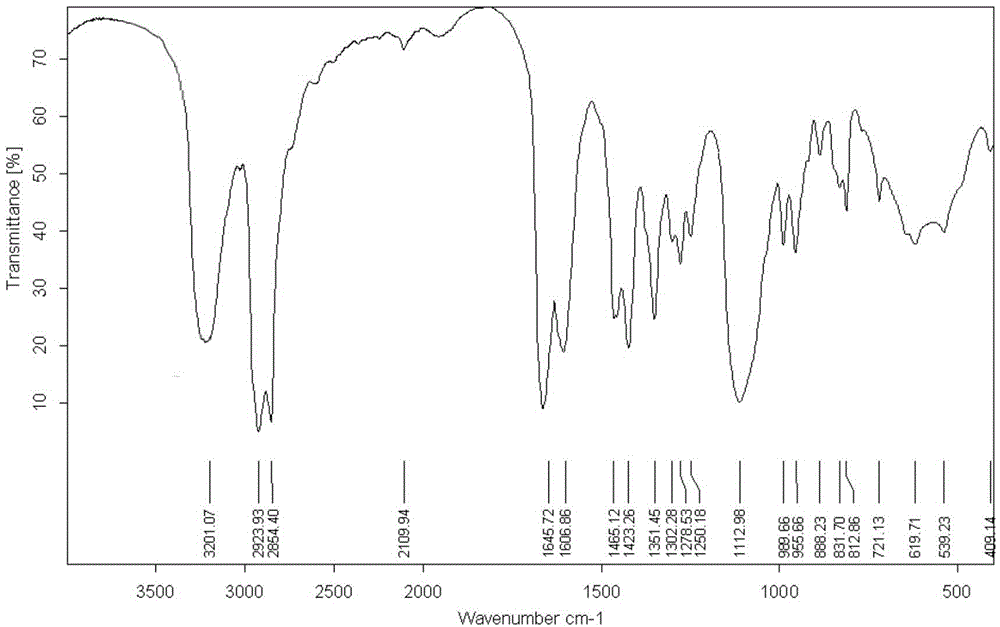

Image

Examples

Embodiment 1

[0027] A includes the following steps:

[0028] 1) Synthesis of Acryloyl Chloride

[0029] Add 72g (1.0mol) of acrylic acid into a three-necked flask equipped with a spherical reflux condenser, a thermometer, and a stirrer, add an appropriate amount of hydroquinone as a polymerization inhibitor, heat to 45°C, and pour into the reaction via a constant pressure dropping funnel. Slowly add 176.4 g (about 1.5 mol) of thionyl chloride dropwise into the system, and use sodium hydroxide solution to absorb the HCl and SO released during the reaction. 2 Gas, after the dropwise addition, continue to react for 0.5-1h, collect the fraction at 80°C-110°C under a vacuum of 0.099Mpa, the transparent liquid is the product, put it in a brown reagent bottle and store it in a low-temperature sealed refrigerator.

[0030] 2) Synthesis of N-acryloyl amino acid: 2-acrylamidopropionic acid

[0031] Stir and dissolve 8.91g (0.1mol) of alanine and 0.1mol of sodium hydroxide in 50% (v / v) of 100ml of ...

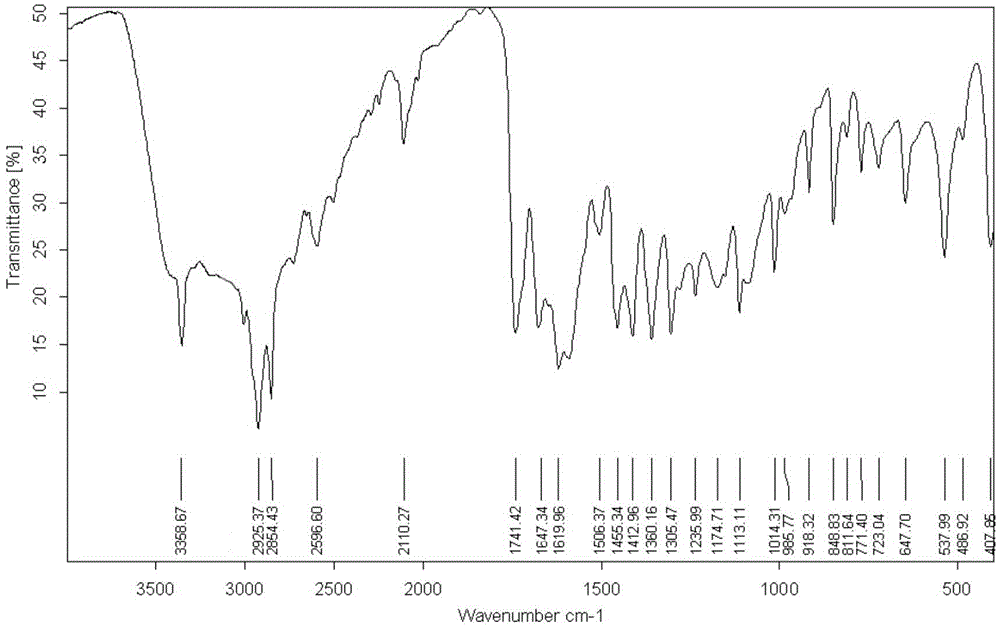

Embodiment 2

[0036] Include the following steps:

[0037] 1) Synthesis of Acryloyl Chloride

[0038] Add 72g (1.0mol) of acrylic acid into a three-necked flask equipped with a spherical reflux condenser, a thermometer, and a stirrer, add an appropriate amount of hydroquinone as a polymerization inhibitor, heat to 45°C, and pour into the reaction via a constant pressure dropping funnel. Slowly add 200 g (about 1.7 mol) of thionyl chloride dropwise into the system, and use sodium hydroxide solution to absorb the HCl and SO released during the reaction. 2 Gas, after the dropwise addition, continue to react for 0.5-1h, collect the fraction at 80°C-110°C under a vacuum of 0.099Mpa, the transparent liquid is the product, put it in a brown reagent bottle and store it in a low-temperature sealed refrigerator.

[0039] 2) Synthesis of N-acryloyl amino acid: 2-acrylamido-3-phenylpropionic acid

[0040] Stir and dissolve 16.52g (0.1mol) of phenylalanine and 0.1mol of sodium hydroxide in 50% (v / v) 1...

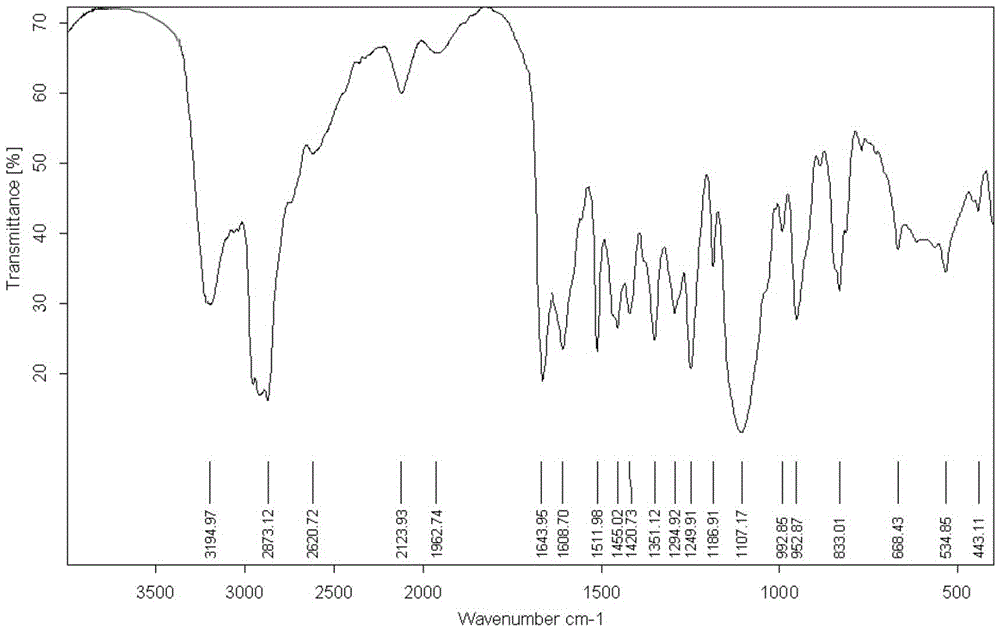

Embodiment 3

[0045] Include the following steps:

[0046] 1) Synthesis of Acryloyl Chloride

[0047] Add 72g (1.0mol) of acrylic acid into a three-necked flask equipped with a spherical reflux condenser, a thermometer, and a stirrer, add an appropriate amount of hydroquinone as a polymerization inhibitor, heat to 45°C, and pour into the reaction via a constant pressure dropping funnel. Slowly add 236 g (about 2.0 mol) of thionyl chloride dropwise into the system, and use sodium hydroxide solution to absorb the HCl and SO released during the reaction. 2 Gas, after the dropwise addition, continue to react for 0.5-1h, collect the fraction at 80°C-110°C under a vacuum of 0.099Mpa, the transparent liquid is the product, put it in a brown reagent bottle and store it in a low-temperature sealed refrigerator.

[0048] 2) Synthesis of N-acryloyl amino acid: 2-acrylamido-3-methylpentanoic acid

[0049] Stir and dissolve 13.12g (0.1mol) of leucine and 0.1mol of sodium hydroxide in 50% (v / v) 100ml o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com