Preparation method of high temperature resistant film-forming styrene-acrylic emulsion for paper product printing

A styrene-acrylic emulsion, high-temperature-resistant technology, applied in applications, household utensils, inks, etc., can solve problems such as high glass transition temperature, achieve low film-forming temperature, improve polymerization stability and temperature resistance, and reduce VOCs emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

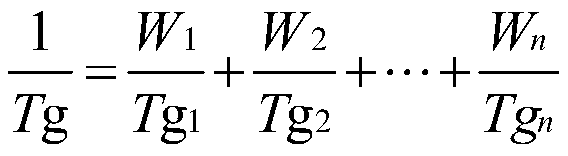

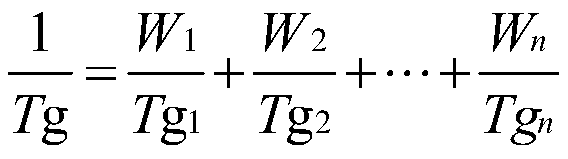

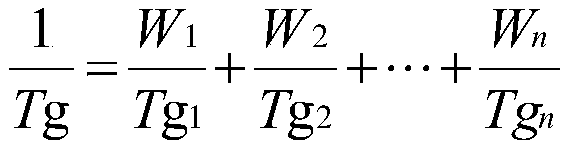

[0033] A preparation method for high temperature resistant film-forming styrene-acrylic emulsion for paper product printing, comprising the following steps:

[0034] S1. Add 5-40 parts by mass of alkali-soluble resin with an acid value of 150-500, 5-15 parts by mass of ammonia water and 45-85 parts by mass of deionized water into the reaction kettle, stir and heat up to 70-85°C, and wait for alkali After the soluble resin is completely dissolved, it is lowered to room temperature, and the pH value is adjusted to 8.0-9.0 with ammonia water, and the resin liquid is prepared for use;

[0035] The alkali-soluble resin is styrene-maleic anhydride resin or styrene-acrylic resin. Such as SMASZ40005 solid resin from POLYSCOPE in the Netherlands, Tianlong TL-669 solid resin, BASF J-678 solid resin, Hanwha S-120 solid resin, SMA SZ25010 solid resin from POLYSCOPE, etc.

[0036] The acid value of the alkali-soluble resin is 200-500, the softening point is 150-300°C, and the dissolution ...

Embodiment 1

[0056] A kind of preparation method of high temperature resistant film-forming styrene-acrylic emulsion for paper product printing:

[0057]S1. Add 320g of POLYSCOPE SMA SZ40005 solid resin with an acid value of 465 and a Tg of 175°C, 120g of ammonia water and 680g of deionized water into the reaction kettle, stir and heat up to 80°C, and cool down to room temperature after the alkali-soluble resin is completely dissolved , adjust the pH value to 8.0-9.0 with ammonia water, and prepare the resin liquid for subsequent use;

[0058] S2. Add 24g Dowfax 2A1 and 16g OP-10 into 80g water and stir to form emulsifier aqueous solution;

[0059] S3. Mix 208g styrene, 272g methyl methacrylate, 40g diacetone acrylamide and 8g dodecyl mercaptan evenly, then add to the emulsifier aqueous solution and stir to emulsify into a pre-emulsion;

[0060] S4. Take 480g of resin liquid and 10% of the pre-emulsion solution into the reaction kettle, stir and heat up to 80°C, then add 8g of ammonium pe...

Embodiment 2

[0065] A kind of preparation method of high temperature resistant film-forming styrene-acrylic emulsion for paper product printing:

[0066] S1. Add 200g of Tianlong TL-669 solid resin with an acid value of 270 (mgKOH / g) and a softening point of 179°C, 80g of ammonia water and 576g of deionized water into the reaction kettle, stir and heat up to 80°C, and wait for the alkali-soluble resin to Cool down to room temperature after complete dissolution, adjust the pH value to 8.0-9.0 with ammonia water, and prepare the resin solution for later use;

[0067] S2. Add 16g of Dowfax 2A1 and 12g of OP-10 into 40g of water and stir to form emulsifier aqueous solution;

[0068] S3. Mix 104g styrene, 136g methyl methacrylate, 24g N-methylolacrylamide and 4.8g dodecyl mercaptan evenly, then add to the emulsifier aqueous solution and stir to emulsify into a pre-emulsion;

[0069] S4. Take 400g of resin liquid and 10% of pre-emulsion solution into the reaction kettle, stir and heat up to 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com