Carboxylic butadiene-styrene latex and preparation technology thereof

A carboxylated styrene-butadiene latex and a preparation process technology, applied in the field of carboxylated styrene-butadiene latex synthesis, can solve the problems of carboxylated styrene-butadiene latex polymerization stability, poor mechanical stability and chemical stability, insufficient polymerization of butadiene and styrene, and reduction of carboxyl groups Problems such as the conversion rate of styrene-butadiene latex, to achieve the effects of not being easy to form agglomerates, short reaction time, and preventing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Embodiment 1: A kind of carboxylated styrene-butadiene latex, wherein the components included are as shown in Table 1, and are prepared through the following steps:

[0089] S1, under vacuum conditions, uniformly mix the first solvent, sodium stearate, acrylic acid, N-methylol acrylamide, acrylamide, and pH regulator in the corresponding weight fraction of the water phase material to form the water phase material;

[0090] S2, under vacuum conditions, the corresponding weight fractions of styrene, butadiene, and ethyl 3-mercaptobutyrate in the oil phase material are mixed uniformly to form the oil phase material;

[0091] S3, mixing the mbs seed latex, sodium dodecylbenzene sulfonate, and liquid caustic soda mixture of the corresponding weight fraction in the primer to form a primer;

[0092] S4, under vacuum conditions, take the fourth solvent in other materials, 260 parts of the water phase material obtained in the step S1, 555 parts of the oil phase material obtained...

Embodiment 2-5

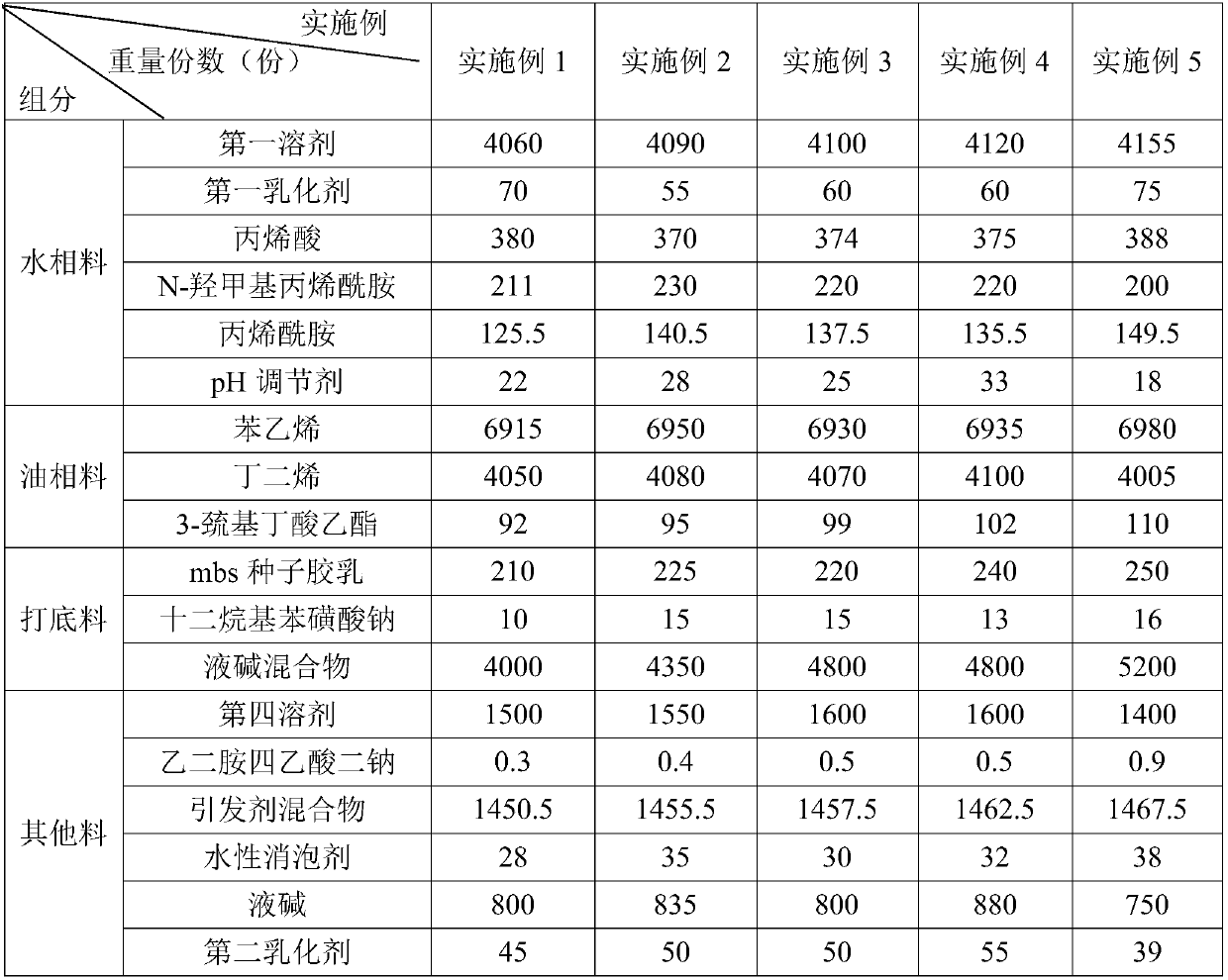

[0097] Example 2-5: A carboxylated styrene-butadiene latex, the difference from Example 1 is that the components included in it are shown in Table 1.

[0098] Components and their corresponding parts by weight in Table 1 Embodiment 1-5

[0099]

Embodiment 6

[0100] Embodiment 6: a kind of carboxylated styrene-butadiene latex, the difference with embodiment 1 is, among other materials, the initiator mixture comprises the initiator and soft water that the ratio of parts by weight is 0.08:1, and the initiator is ammonium persulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com