Dispersion stabilizer for suspension polymerization and method for producing vinyl polymer using same

A technology of dispersion stabilizer and vinyl compound, which is applied in the field of manufacture of dispersion stabilizer for suspension polymerization and vinyl-based polymers using the same, can solve the problems of insufficient demand, many insoluble components in aqueous solution, and many fish eyes, etc. , to achieve the effect of coarse-grained inhibition, fish-eye reduction, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0098] Hereinafter, the present invention will be explained in further detail through examples. In the following examples and comparative examples, unless otherwise specified, "parts" and "%" respectively represent parts by mass and% by mass, and ppm represents ppm by mass.

[0099] [Viscosity average degree of polymerization of PVA(A)]

[0100] The viscosity average degree of polymerization of PVA (A) is measured in accordance with JIS K 6726:1994. Specifically, when the degree of saponification of PVA (A) is less than 99.5 mol%, for PVA saponified until the degree of saponification reaches 99.5 mol% or more, the intrinsic viscosity measured in water at 30°C [η](L / g) The viscosity average degree of polymerization (P) is obtained by the following formula.

[0101] P=([η]×10 4 / 8.29) (1 / 0.62)

[0102] [Saponification degree of PVA(A)]

[0103] The saponification degree of PVA(A) is measured in accordance with JIS K 6726:1994.

[0104] [The content of the terminal propyl group of PVA(A...

manufacture example 1-1

[0115] [Production Example 1-1 Production of PVA (A1-1)]

[0116] After charging 1500 parts of vinyl acetate (hereinafter sometimes referred to as "VAc"), 30 parts of methanol, and 6.7 parts of trimethylolpropane diallyl ether into the polymerization tank, 25.5 parts of acetaldehyde was additionally charged after nitrogen replacement, The temperature was raised to 60°C by heating, and polymerization was performed in the presence of 2,2'-azobis(isobutyronitrile) as an initiator until the polymerization rate reached 50%. While adding methanol, an operation of discharging the remaining VAc and methanol to the outside of the system under reduced pressure was performed to obtain a methanol solution (concentration 50% by mass) of a vinyl ester copolymer (hereinafter sometimes referred to as “PVAc”). Next, in a mixed solvent of methanol and methyl acetate (the concentration of methyl acetate is 10% by mass relative to the total saponification system), the concentration of the vinyl este...

manufacture example 1-2~1-16

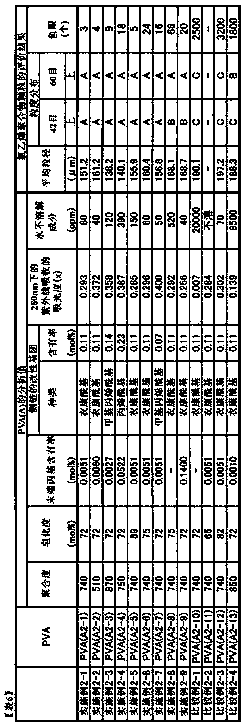

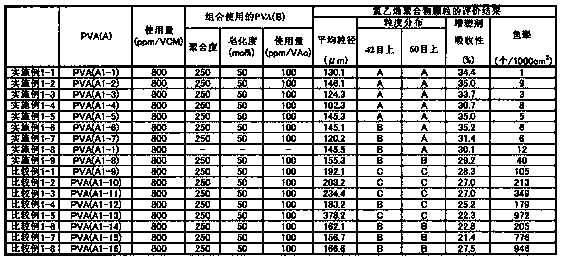

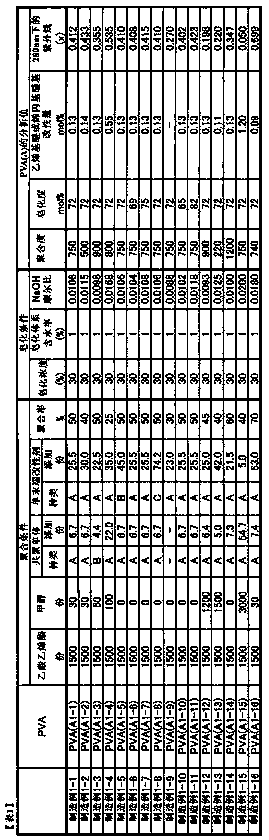

[0117] [Manufacturing example 1-2~1-16 PVA (A1-2)~(A1-16) manufacturing]

[0118] Change the usage amount of vinyl acetate and methanol, the type and usage amount of monomers with two or more olefinic double bonds, the type and usage amount of single-terminal modifier, and the polymerization rate as described in Tables 1 to 3, Except for the saponification conditions, PVA (A1-2) to PVA (A1-16) were produced in the same manner as in Production Example 1. The production conditions and production results are shown in Table 1, the types of monomers used are shown in Table 2, and the types of single-end modifiers used are shown in Table 3.

[0119]

[0120] 【Table 2】

[0121] species Comonomer A Trimethylolpropane diallyl ether B 1,4-butanediol divinyl ether

[0122] 【table 3】

[0123] species Single terminal modifier A Acetaldehyde B Butyraldehyde C Octanal

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com