Dispersion stabilizer for suspension polymerization, and manufacturing method for vinyl resin

A technology of dispersion stabilizer and suspension polymerization, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problems of unsatisfactory performance and unsatisfactory performance, and achieve high polymerization stability, less formation, and excellent operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

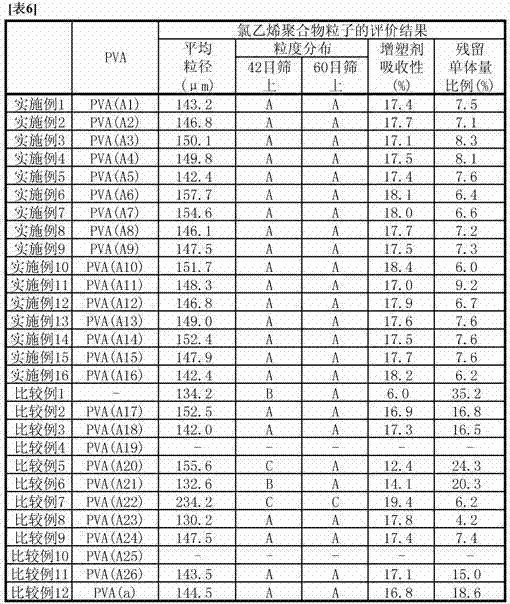

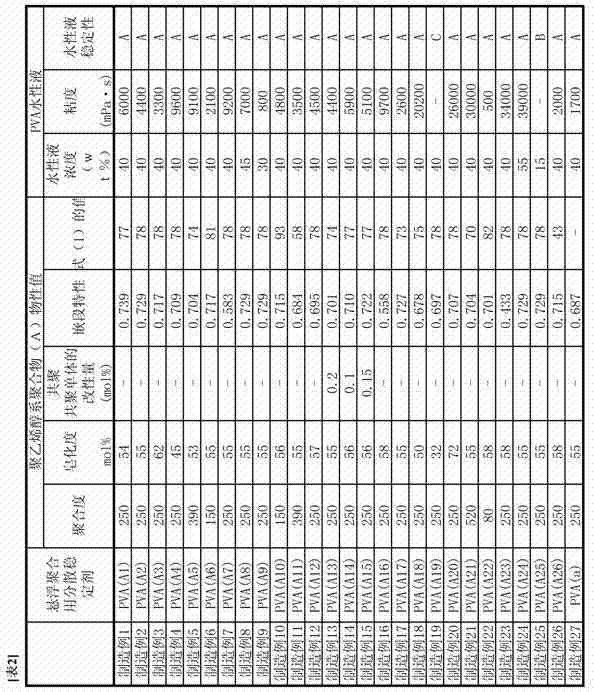

[0090] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited to these examples. In the following examples and comparative examples, unless otherwise specified, "parts" and "%" represent "parts by mass" and "% by mass", respectively.

[0091] About the PVA obtained by the following manufacture example, it evaluated by the following method.

[0092] [Viscosity average degree of polymerization of PVA]

[0093] The viscosity-average degree of polymerization of PVA can be calculated as follows: After substantially completely saponifying PVA, it is acetylated to produce a vinyl ester polymer, and is measured based on the intrinsic viscosity of the acetone solution of the vinyl ester polymer, using Nakajima Calculation formula (Akio Nakajima: Polymer Chemistry 6 (1949)) to calculate.

[0094] [Saponification degree of PVA]

[0095] The degree of saponification of PVA was determined by the method described i...

manufacture example 2~12、17~26

[0112] Production examples 2-12, 17-26 (manufacture of PVA (A2-A12, A17-A26))

[0113] The amount of vinyl acetate and methanol added, the type and amount of chain transfer agent having an aliphatic hydrocarbon group used during polymerization, the concentration of addition, the amount of initiator used, the target polymerization rate, and other polymerization conditions, saponification conditions, and aqueous solution concentration The dispersion stabilizer for suspension polymerization shown in Table 2: PVA (A2-A12, A17-A26) was manufactured similarly to the manufacture example 1 except having changed. The production conditions are shown in Table 1, and the types of chain transfer agents used and saponification conditions are shown in Tables 3 and 5, respectively.

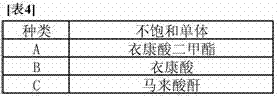

manufacture example 13~15

[0114] Manufacturing Examples 13-15 (Manufacturing of PVA (A13-A15))

[0115] In addition to changing the polymerization conditions such as the type of chain transfer agent having an aliphatic hydrocarbon group used during polymerization, its usage amount, addition concentration, and initiator usage amount, the unsaturated monomer for copolymerization is added in advance, and after the start of polymerization The dispersion stabilizer for suspension polymerization shown in Table 2: PVA was produced in the same manner as in Production Example 1, except that the concentration of the unsaturated monomer to be copolymerized was always constant with respect to VAc, and the methanol solution of the unsaturated monomer was continuously added to carry out polymerization. (A13~A15). The production conditions are shown in Table 1, and the types of chain transfer agents used and unsaturated monomers used are shown in Tables 3 and 4, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com