Automotive wear-resistant plant fiber reinforced polypropylene micro-foaming material and preparation method thereof

A plant fiber and polypropylene technology, applied in the field of materials, can solve the problems of being unable to be directly used in auto parts, poor surface wear resistance of micro-foaming products, and unable to meet the requirements of use, and meet the requirements of non-toxic and harmless substances, The effect of improving wrapping ability and improving interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

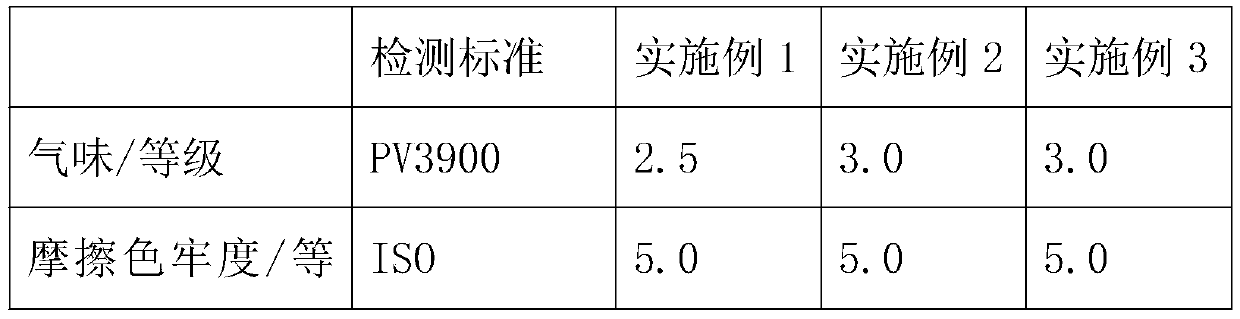

Embodiment 1

[0031] Example 1

[0032] (1) 40 parts of copolymerized polypropylene with a melt index of 25g / 10min, 8 parts of maleic anhydride grafted polypropylene with 0.2% monomer residual content, 10 parts of quartz sand, 3 parts of synthetic polyethylene wax, dehydroabietic acid 0.5 parts of potassium, 10 parts of POE, 2 parts of allicin, 3 parts of camphor powder, 4.5 parts of porous aluminum silicate, 0.2 parts of Cytec 3808, and 168 0.3 parts of antioxidant are added to the mixer in parts by weight and mixed for 1 min, Then add the mixture to the twin-screw extruder to obtain material A; meanwhile, 25 parts of bamboo fiber (0.5% moisture content) is fed into the extruder in parts by weight through the side feeding port, and undergoes plasticization, shearing and dispersion, Extrusion, drawing, air drying, and granulation to obtain material B. Among them, the temperature of the extruder is set at 180-270°C, and the screw speed is 800r / min.

[0033] (2) Put 106.5 parts of the polypropyle...

Embodiment 2

[0035] (1) 60 parts of homopolymerized polypropylene with a melt index of 20g / 10min, 20 parts of copolymerized polypropylene with a melt index of 30g / 10min, 1 part of maleic anhydride with 0.5% residual monomer content, and glass beads 1 part, 0.5 parts of silicone wax, 5 parts of sodium meta-benzoate, 1 part of EPDM, 1 part of camphor powder, 1.5 parts of porous calcium silicate, 0.3 parts of Cytec 3808, 0.2 parts of antioxidant 1010, and 0.2 parts by weight. Mix in the machine for 4 minutes, and then add the mixture to the twin-screw extruder to obtain material A; at the same time, 10 parts of wood flour (water content 1%) is fed into the extruder in parts by weight through the side feeding port, and is plasticized , Shearing and dispersing, extruding, stretching, air drying, and granulating to obtain material B, wherein the temperature of the extruder is set at 180-270℃, and the screw speed is 400r / min.

[0036] (2) Put 101.5 parts of polypropylene composite material particles...

Embodiment 3

[0038] (1) 60 parts of copolymerized polypropylene with a melt index of 30g / 10min, 5 parts of maleic anhydride grafted polyethylene with a monomer residual content of 0.2%, 7 parts of alumina ceramsite, 2 parts of silicone powder, dehydrogenated fir Add 1 part of sodium sulfate, 5 parts of polyethylene, 4 parts of zinc oxide, 3 parts of activated carbon, 0.3 parts of Cytec 3808, 0.5 parts of antioxidant 1010, and add them to the mixer for 3 minutes by weight, and then add the mixture to the double Material A is obtained from the screw extruder; at the same time, 20 parts of hemp fiber (water content 0.3%) is fed into the extruder in parts by weight through the side feeding port, and undergoes plasticization, shearing and dispersion, extrusion, drawing, and air drying. , Pelletizing to obtain material B, wherein the temperature of the extruder is set at 180-270℃, and the screw speed is 600r / min.

[0039] (2) Put 107.8 parts of polypropylene composite material particles obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com