Sealing system for refrigeration cassette

a refrigeration cassette and sealing system technology, applied in the field of refrigeration merchandisers, can solve the problems of increasing the workload of the evaporator, reducing the efficiency of the refrigeration operation, etc., and achieve the effect of facilitating the removal of the refrigeration unit cass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

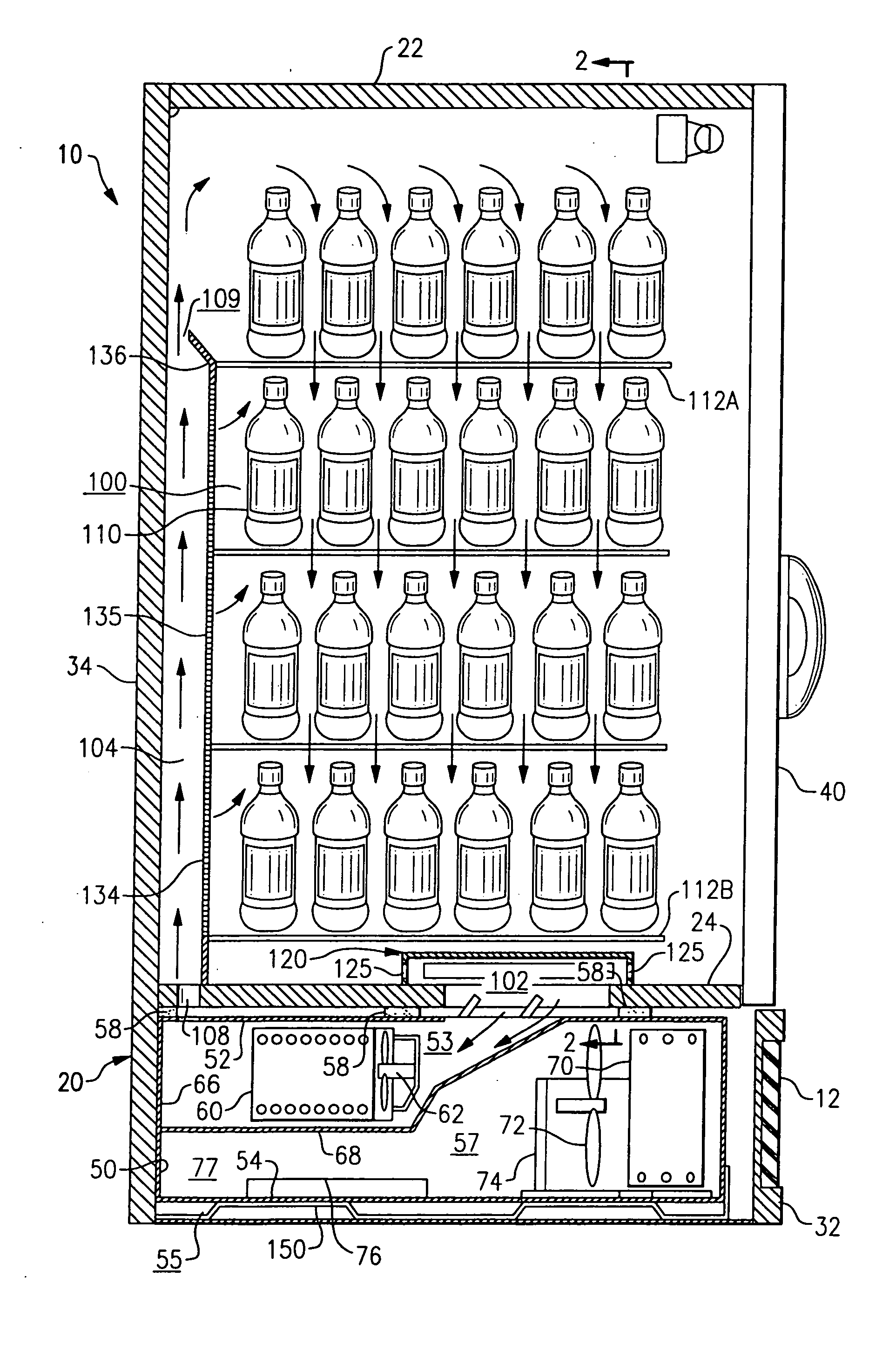

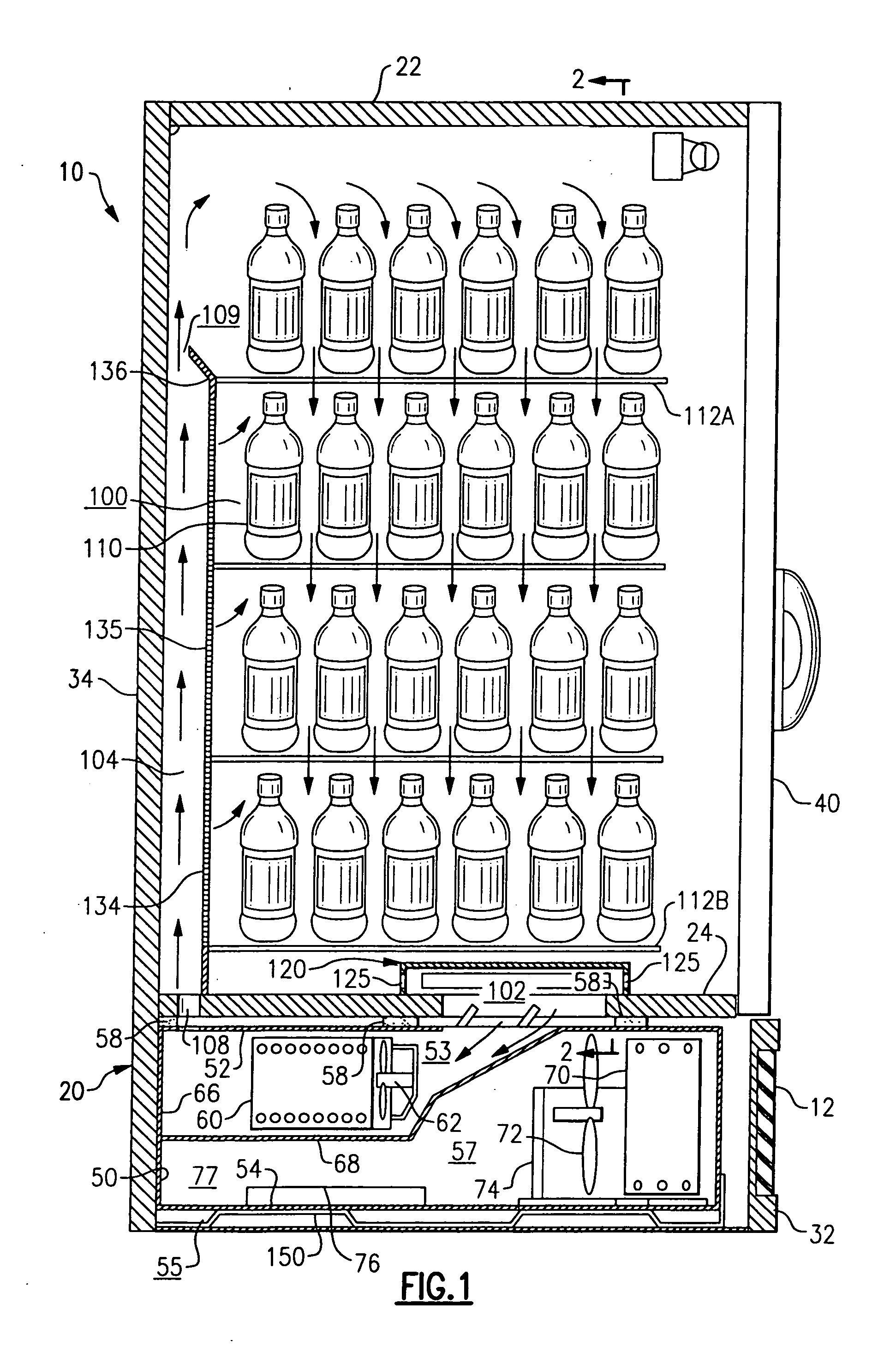

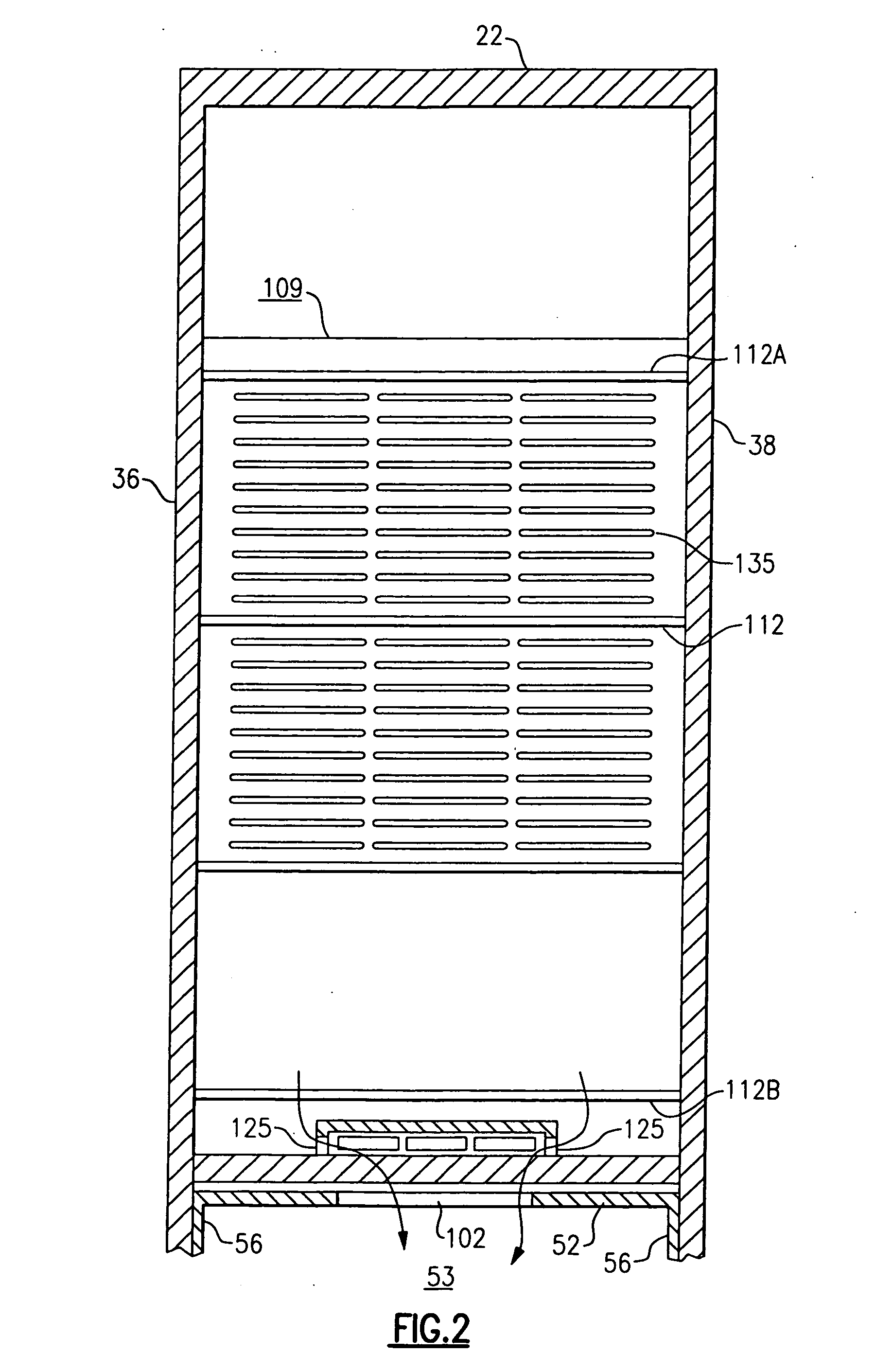

[0032] Referring now to FIGS. 1 and 2 in particular, there is depicted a refrigerated cold beverage merchandiser, designated generally by the reference numeral 10, including an interior product display space 100 for holding product 110 to be purchased, such as for example bottled or canned soda, milk, water, juices, fruit drinks, beer and other beverages. Although the invention will be described herein with reference to the depicted embodiment of a refrigerated cold beverage merchandiser, it is to be understood that that invention may be applied to other refrigerated display merchandisers for displaying perishable and frozen comestibles and beverages, including for example meats, poultry, fish, diary products, prepackaged frozen foods, and other products that need to be maintained in a controlled environment.

[0033] The beverage merchandiser 10 includes a cabinet 20 housing a refrigerated interior product display space 100 and a separate equipment compartment 55 disposed separate fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com