Environmentally friendly hot melt adhesive membrane for automotive interior products, preparation method and application

A technology for automotive interior parts and hot-melt adhesive films, which is used in adhesives, film/flake adhesives, adhesive additives, etc. The effect of good body strength and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

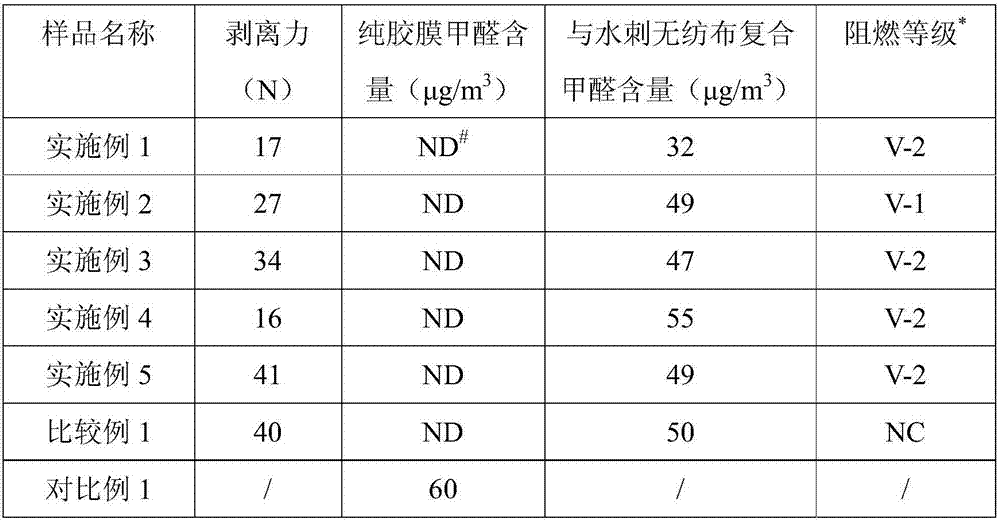

Examples

Embodiment 1

[0025] The environmental protection hot-melt adhesive film of present embodiment is composed as follows:

[0026] Elastomer component (ethylene-octene copolymer, melt index: 15g / 10min, 190°C, 2.16kg): 100 parts by mass

[0027] Non-elastic component (high-density polyethylene, melt index: 0.9g / 10min, 190°C, 2.16kg): 30 parts by mass

[0028] Composite filler: 12 parts by mass

[0029] Wherein the composite filler consists of:

[0030] Bamboo charcoal fiber: 30%

[0031] Fiberglass: 10%

[0032] Odor adsorbent (activated carbon): 35%

[0033] Nano Filler (Nano Silica): 5%

[0034] Flame retardant filler: 20%

[0035] The preparation method is as follows: add the above raw materials into a twin-screw extruder, melt and blend the polymers, and then extrude into a film to obtain a grammage of 20g / m 2 product. Carry out the test of bonding strength, VOC, antibacterial property, flame retardancy, after the test method is attached to the embodiment, the test results are shown...

Embodiment 2

[0037] The environmental protection hot-melt adhesive film of present embodiment is composed as follows:

[0038] Elastomer component (ethylene-vinyl acetate copolymer 50%, melt index: 9g / 10min, 190°C, 2.16kg, styrene-isoprene-styrene block copolymer 50%, melt index: 1g / 10min 10min, 190°C, 2.16kg): 100 parts by mass

[0039] Non-elastic components (isotactic copolymerized polypropylene 70%, melt index: 0.3g / 10min, 190°C, 2.16kg, low-density polyethylene 30%, melt index: 1g / 10min, 190°C, 2.16kg): 2 mass share

[0040] Composite filler: 20 parts by mass

[0041] Wherein the composite filler consists of:

[0042] Bamboo charcoal fiber: 30%

[0043] Fiberglass: 10%

[0044] Odor adsorbent (activated carbon 10%, porous silica 90%): 20%

[0045] Nano Filler (Nano Silica): 5%

[0046] Flame retardant filler: 35%

[0047] The preparation method is: add the above raw materials into a twin-screw extruder, melt and blend the polymers and extrude to form a film to obtain a grammage ...

Embodiment 3

[0049] The environmental protection hot-melt adhesive film of present embodiment is composed as follows:

[0050] Elastomer component (ethylene-octene copolymer, melt index: 5g / 10min, 190°C, 2.16kg): 100 parts by mass

[0051] Non-elastic component (high-density polyethylene, melt index: 0.9g / 10min, 190°C, 2.16kg): 50 parts by mass

[0052] Composite filler: 4 parts by mass

[0053] Wherein the composite filler consists of:

[0054] Bamboo charcoal fiber: 30%

[0055] Fiberglass: 10%

[0056] Odor adsorbent (activated carbon): 20%

[0057] Nano filler (nano silica 10%, bentonite 10%): 20%

[0058] Flame retardant filler: 20%

[0059] The preparation method is: add the above raw materials into a single-screw extruder, melt and blend the polymers and extrude them into films to obtain a grammage of 80g / m 2 product. Carry out the test of bonding strength, VOC, antibacterial property, flame retardancy, after the test method is attached to the embodiment, the test results ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com