Front-edge cutting device for automotive interior canopy

A technology for automotive interior parts and cutting devices, applied in metal processing and other directions, can solve the problems of long time and high cost of robotic water jet cutting, and achieve the effects of reducing production costs, simple structure, and power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

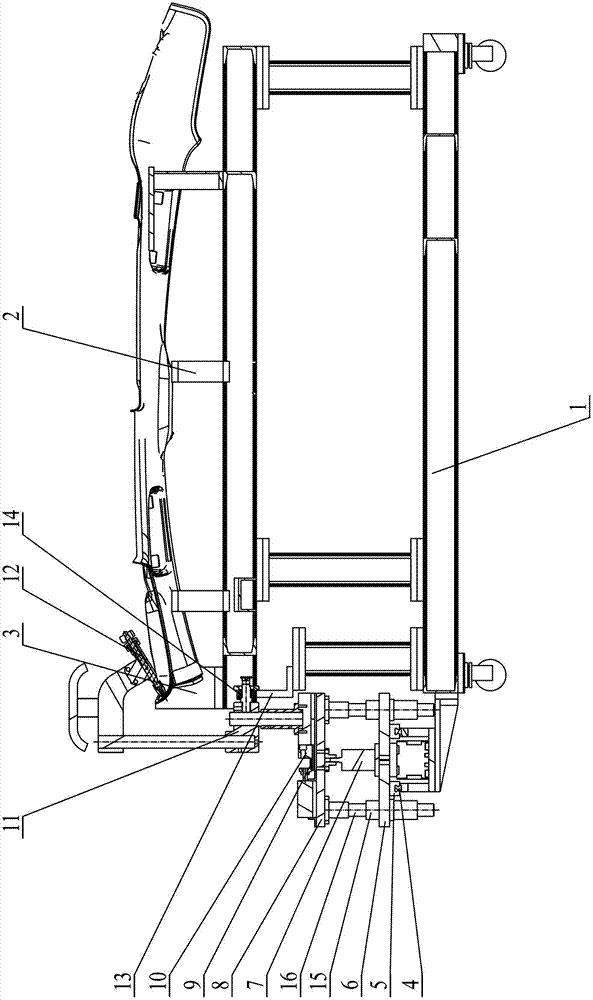

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0009] As shown in the figure: the cutting device for the front edge of the roof of the automotive interior parts is fixed with a roof positioning module 2 and a roof front positioning tire mold 3 at the top of the frame 1, and an inner and outer line rail 4 is fixed on the frame 1. On the inner and outer line rails 4, the inner and outer sliders 5 are slidably connected, and the movement of the inner and outer sliders 5 is promoted by a rodless cylinder. The lift cylinder 7 is fixed with a left and right base 8 at the end of the piston rod of the lift cylinder 7, and the lift of the left and right base 8 is promoted by the lift cylinder 7, and the left and right line rails 9 are fixed on the left and right base 8. Slider 10 is connected with left and right on line rail 9, and the movement of left and right to slide 10 is promoted by left and right air cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com