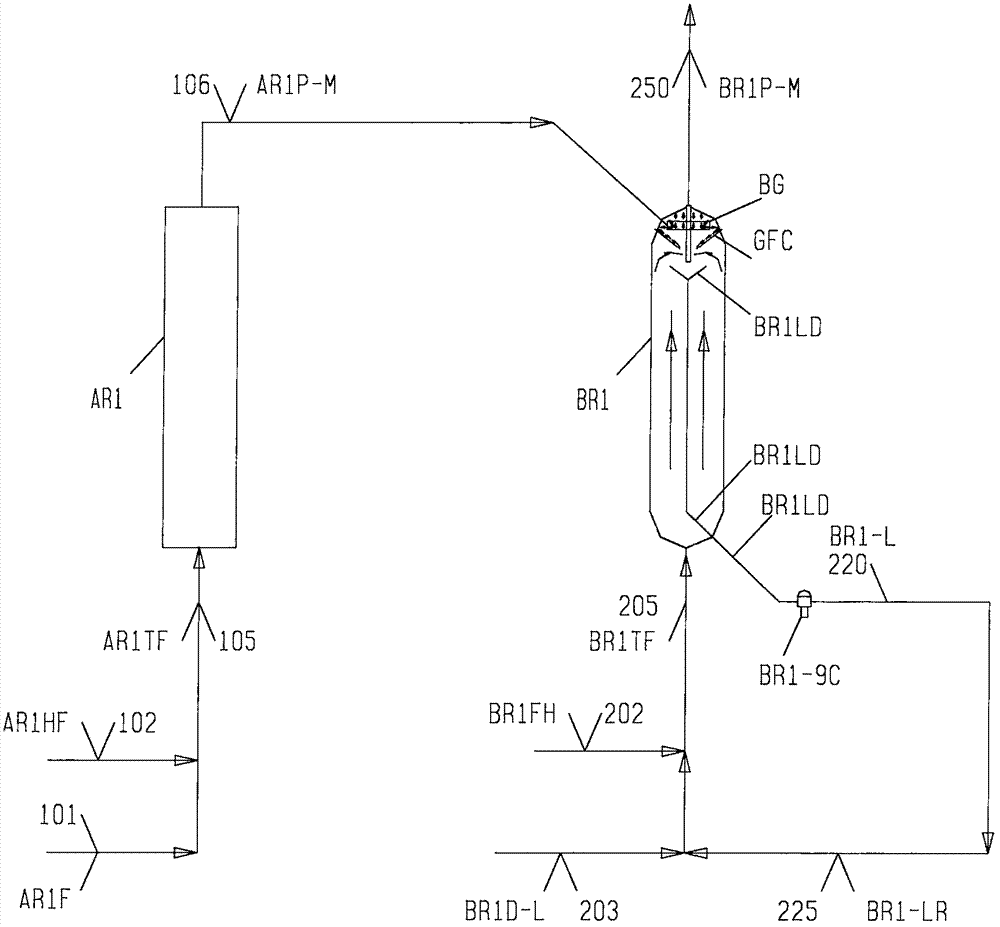

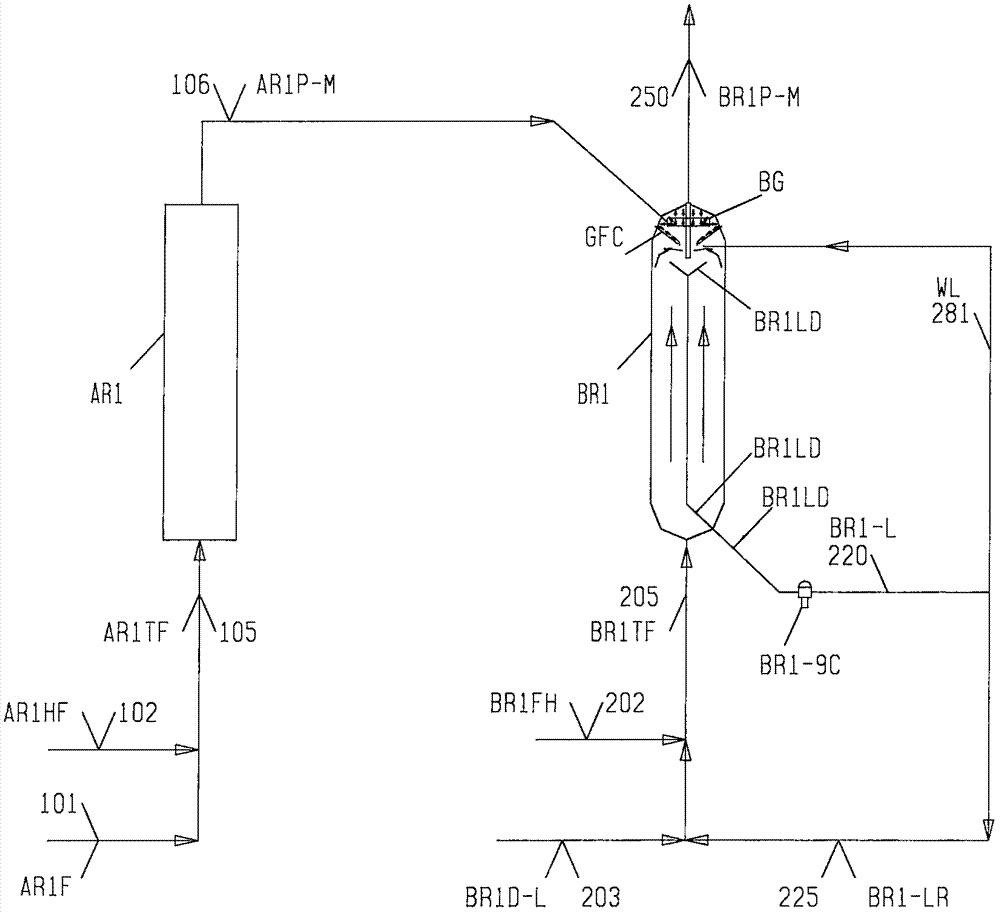

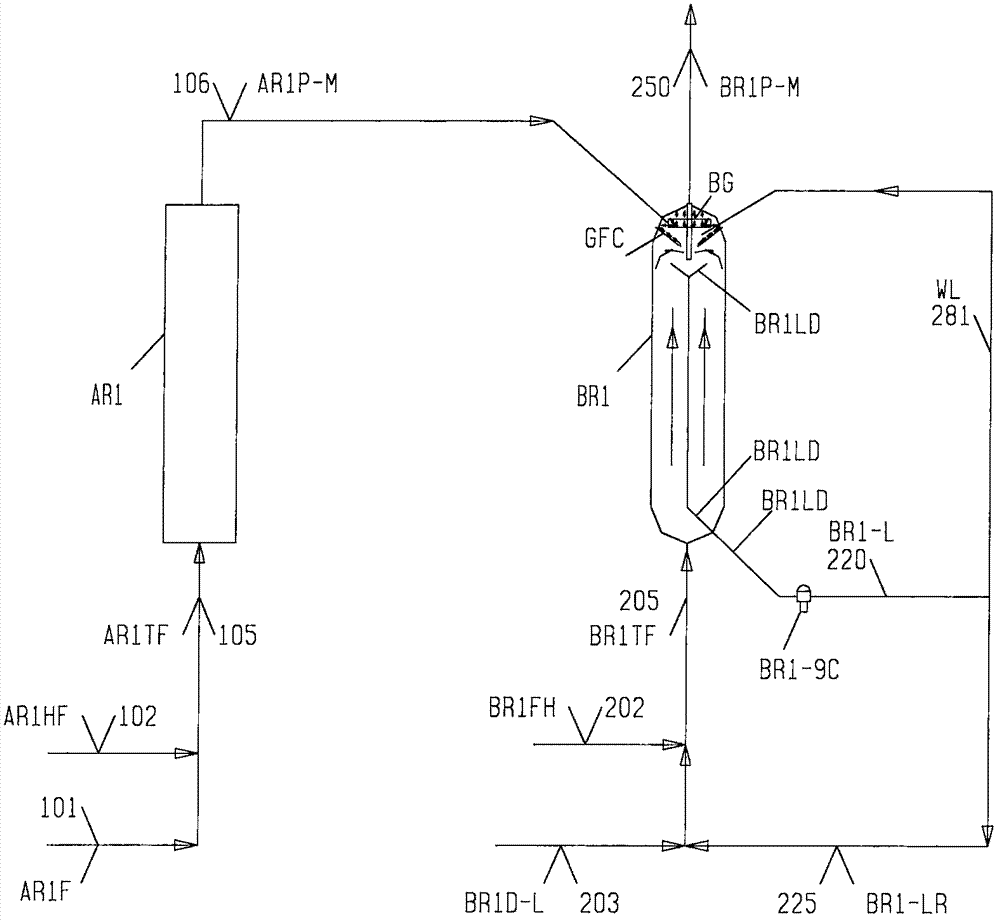

Backmixing-flow expanded-bed hydrogenation reactor system with distributor for hydrocarbon-containing gas-liquid upper feed

A hydrogenation reactor and hydrogenation reaction technology, which are applied in the directions of hydrotreating process, treatment of hydrocarbon oil, chemical instruments and methods, etc., can solve problems such as unreported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0150] The present invention uses the back-mixed flow expanded bed hydrogenation reactor system of hydrocarbon-containing gas-liquid upper feed distributor, and is characterized in that comprising the following steps:

[0151] (1) In the first hydrogenation reaction process AR, in the presence of hydrogen, liquid phase hydrocarbons and solid particles, the first raw material AR1F containing at least carbon and hydrogen elements enters the first hydrogenation reaction process AR for a first stage The hydrogenation reaction ARR obtains a hydrogenation reaction product BASE-ARP, discharges a hydrogenation reaction effluent ARP-X, and discharges a hydrogenation reaction process net product ARP;

[0152] The first raw material AR1F, including the liquid raw material AR1FL and the possible solid particle raw material AR1FS;

[0153] In the first stage of hydrogenation reaction process AR, hydrogen gas, liquid phase hydrocarbons and solid particles may exist at the same time;

[015...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com