Cold forming mold for automobile carpet

A car carpet, cold forming technology, applied in the direction of household appliances, other household appliances, household components, etc., can solve the problem of easy tearing or wrinkling of carpets, and achieve stable and reliable product quality, simple structure, avoid tearing or wrinkled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

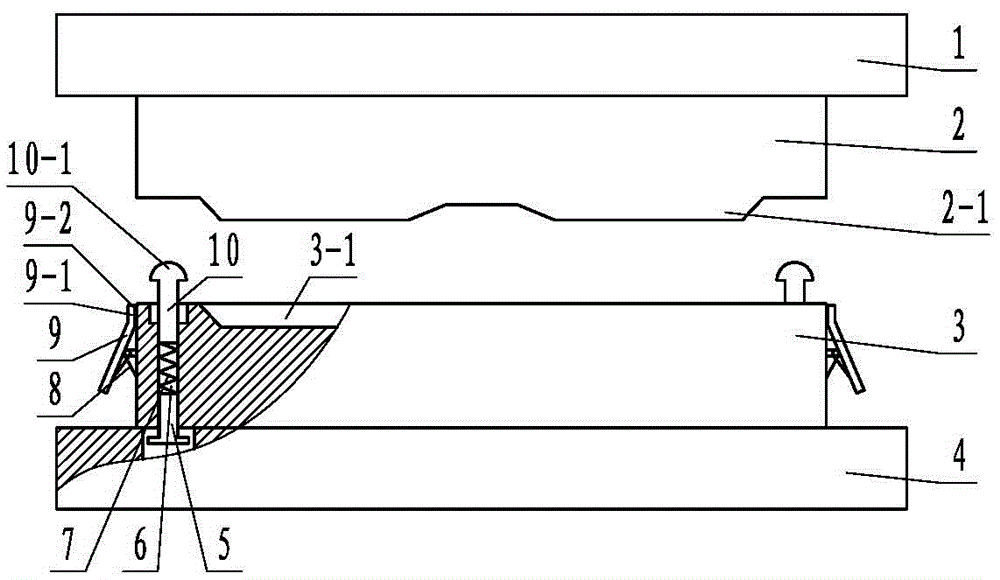

[0013] figure 1 The car carpet cold forming mold shown mainly comprises upper mold base 1, upper mold 2, lower mold 3, lower mold base 4 and pressing device, wherein upper mold 2 is provided with punch 2-1, and lower mold 3 is provided with The die cavity 3-1 that the punch 2-1 cooperates. The opposite sides of lower die 3 are all provided with pressing devices, and each side of lower die 3 is symmetrically provided with two pressing devices, and the pressing devices are pressing arms 9 hinged with lower die 3, and the hinge shafts of pressing arms 9 A torsion spring 8 is installed on the top, and the two torsion arms of the torsion spring 8 abut against the outer wall of the lower mold 3 and the pressing arm 9 respectively; The indenter 9-1, and the abutment surface of the indenter 9-1 is provided with anti-slip protrusions 9-2; on the lower mold 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com