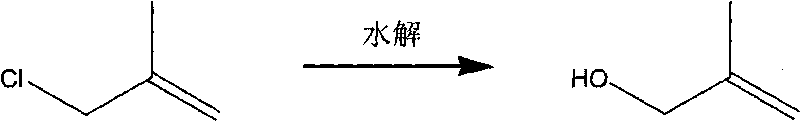

Synthesizing method of 2-methallyl alcohol

The technology of a kind of methallyl alcohol and synthetic method is applied in the synthetic field of 2-methallyl alcohol, can solve the problems such as raising production cost, high production cost, difficult DMF solvent, reaches the generation that avoids by-product ether, The effect of avoiding post-treatment process and improving reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The polyethylene glycol (PEG) used in the experiment of the embodiment adopts PEG-6000.

[0032] (1) Add 1000ml of water, 30g of sodium hydroxide (96% content), 240g of 2-methallyl chloride, and 0.5g of PEG-6000 to a 2L reaction flask in sequence; heat and reflux the reaction system obtained above, and prepare another 120g of sodium hydroxide dissolved in 200ml of aqueous hydroxide liquid solution in 200ml of water, within 5.5 hours, the above prepared sodium hydroxide aqueous solution was added dropwise to the reaction system heated to reflux; through GC detection, the 2-methylene in the reaction solution When the content of propyl chloride is less than 0.2%, the reaction is finished, the reaction time is 6.5h, and the volume of the reaction system is 1400ml;

[0033] (2) The reaction solution after the above-mentioned reaction is cooled, left to stand, layered, and the obtained organic layer is about 150g; the organic layer is dried and dehydrated with anhydrous sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com