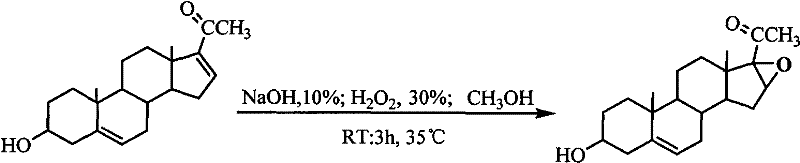

Method for synthesizing 3beta-hydroxy-16alpha,17alpha-epoxy-5-pregnene-20-ketone

A synthesis method and technology of pregnene, applied in the directions of steroids, organic chemistry, etc., can solve the problems of increased production cost, low melting point of products, and increased procedures, so as to reduce the influence of by-products, avoid post-processing procedures, and improve Effects of Purity and Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Take 3.0 kg of diene, add 270 L of methanol, heat to 40 ° C, stir to dissolve and cool down to 27 ° C, slowly add 18.6 L of 30% H 2 o 2 , 9.6 L10% NaOH, 6 L30% H 2 o 2 and 6 L10% NaOH, the temperature of the reaction system is controlled at 29°C, H 2 o 2 After adding the NaOH solution, the temperature of the reaction system was raised to 35° C., and the reaction was kept for 3 hours. Distilled under reduced pressure to obtain a white solid, which was filtered by suction, rinsed until neutral, and dried at 105°C to obtain 2.985kg of white oxygen bridge with a melting point of 189.6-191.1°C and a yield of 98.9%.

Embodiment 2

[0014] Take 4.0kg of diene, add 180L of methanol, heat to 40°C, stir to dissolve and cool down to 26°C, slowly add 25.2L of 30%H 2 o 2 , 12.4L10%NaOH, 8.4L30%H 2 o 2 and 4L10% NaOH, control the temperature of the reaction system at 30°C, H 2 o 2 After adding the NaOH solution, the temperature of the reaction system was raised to 34° C., and the reaction was kept for 3 hours. Distilled under reduced pressure to obtain a white solid, which was filtered with suction, rinsed until neutral, and dried at 105°C to obtain 3.984kg of white oxygen bridge with a melting point of 189.7-191.2°C and a yield of 99.0%.

Embodiment 3

[0016] Take 5.0kg of diene, add 225L of methanol, heat to 40°C, stir to cool the solution to 26°C, and slowly add 31.50L of 30%H 2 o 2 , 15.75L10%NaOH, 10.50L30%H 2 o 2 and 5.25L of 10% NaOH, the temperature of the reaction system is controlled at 31°C, H 2 o 2 After adding the NaOH solution, the temperature of the reaction system was raised to 34° C., and the reaction was kept for 3 hours. Distilled under reduced pressure to obtain a white solid, which was filtered with suction, rinsed until neutral, and dried at 105°C to obtain 4.985kg of white oxygen bridge with a melting point of 189.5-190.8°C and a yield of 99.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com