Phenol-resistant yellow masterbatch, preparation method thereof, use and phenol yellow nylon

A functional masterbatch and phenol-resistant technology, applied in the field of phenolic yellow nylon, its preparation, and phenolic yellow-resistant functional masterbatch, can solve the problems of complex post-processing process, affecting production efficiency, existence of effective substances, etc., to avoid post-processing The process and the effect are long-lasting, and the effect of improving the resistance to phenol yellow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a phenol yellow-resistant functional masterbatch, including the following components in parts by weight:

[0051] PA6 30 copies;

[0052] 15 parts of methyl-terminated polydimethylsiloxane;

[0053] 5 parts of acetic acid;

[0054] Among them, the number average molecular weight of the methyl-terminated polydimethylsiloxane is 200,000.

[0055] The preparation method of the above-mentioned phenol yellow resistant functional masterbatch is as follows:

[0056] Add the components of the formula amount into the high-speed mixer, stir and mix at a speed of 300r / min for 10min; then add the obtained mixture into the twin-screw extruder, set the screw speed to 1800r / min, and the speed of the feeding zone 720r / min, extruded at 245°C to obtain phenol yellow resistant functional masterbatch.

Embodiment 2

[0058] This embodiment provides a phenol yellow-resistant functional masterbatch, including the following components in parts by weight:

[0059] PA66 50 copies;

[0060] 8 parts of hydroxyl-terminated polydimethylsiloxane;

[0061] 12 parts of stearic acid;

[0062] Among them, the number average molecular weight of the hydroxyl-terminated polydimethylsiloxane is 250,000.

[0063] The preparation method of the above-mentioned phenol yellow resistant functional masterbatch is as follows:

[0064] Add the components of the formula amount into a high-speed mixer, and stir and mix for 5 minutes at a speed of 500r / min; then add the obtained mixture into a twin-screw extruder, set the screw speed to 900r / min, and the speed in the feeding zone Extrude at 480r / min at 300°C to obtain phenol yellow-resistant functional masterbatches.

Embodiment 3

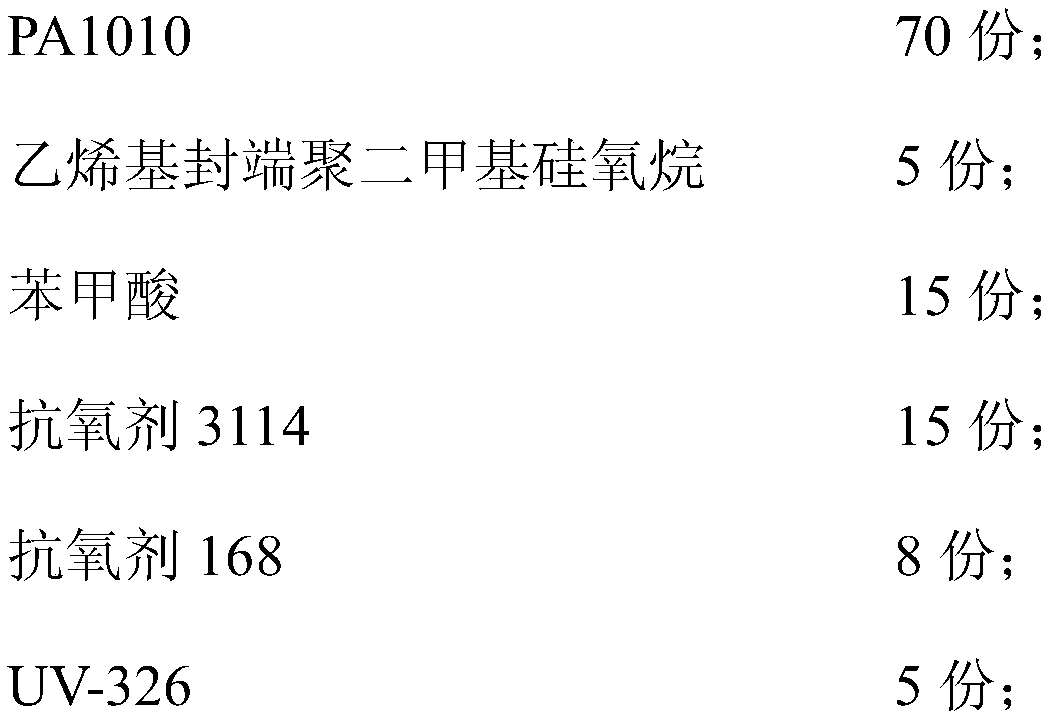

[0066] This embodiment provides a phenol yellow-resistant functional masterbatch, including the following components in parts by weight:

[0067]

[0068] Among them, the number average molecular weight of the vinyl-terminated polydimethylsiloxane is 150,000.

[0069] The preparation method of the above-mentioned phenol yellow resistant functional masterbatch is as follows:

[0070] Add the components of the formula amount into the high-speed mixer, stir and mix at a speed of 400r / min for 8min; then add the obtained mixture into the twin-screw extruder, set the screw speed to 1000r / min, and the speed of the feeding zone Extrude at 500r / min at 260°C to obtain functional masterbatches resistant to phenol yellow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com