Production process of copper-aluminum transition wiring terminal with limiting constraint conditions

A technology of terminals and constraints, applied in the field of production technology of copper-aluminum transition terminals, can solve the problems of high scrap rate and high production cost in the production process, and achieve the effects of high degree of automation, improved service life and reduced expenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

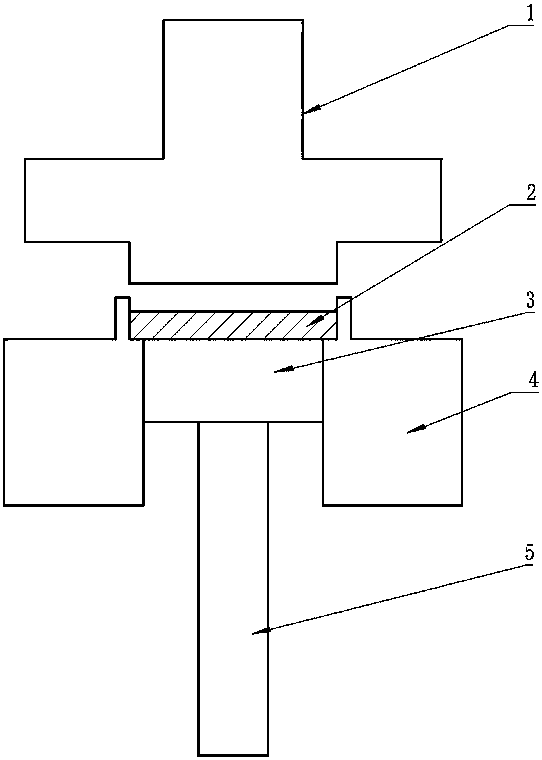

Image

Examples

Embodiment Construction

[0020] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: a production process of a copper-aluminum transition terminal with limit constraints, including the following steps:

[0021] Step 1: Roll the copper-aluminum composite billet into round bars of various specifications;

[0022] The second step: complete the bright annealing of the round bar by adding a protective gas of argon. The main advantage of using argon protection for annealing is that it not only meets the conditions of high temperature annealing and residual oil stains on the burning surface, but also protects the surface of the material. Prevent oxidation, save the acid-base washing procedure, realize green production, avoid environmental pollution, and also save the post-treatment procedure of acid-base waste liquid;

[0023] Step 3: Cut to length according to the cutting size, and remove the surface burrs;

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com