3D-printed gradient ceramic-metal material and production method

A ceramic metal, 3D printing technology, applied in the field of 3D printing, can solve the problems of different powder sintering temperature difference sintering shrinkage of different layers, less application of gradient ceramic materials, etc., to reduce residual stress and thermal stress, eliminate stress singularity, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

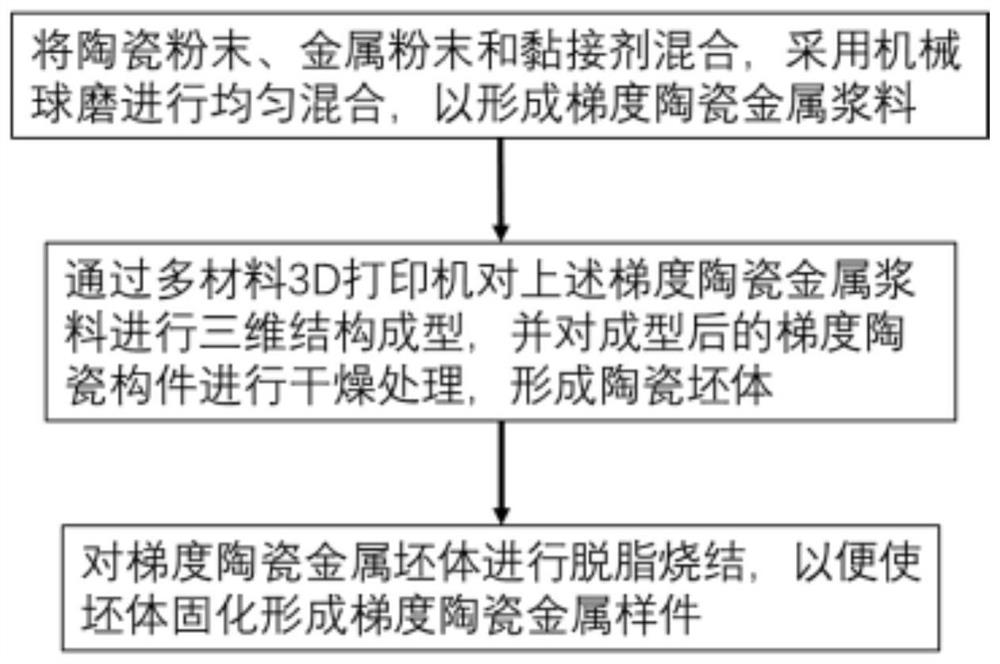

Method used

Image

Examples

Embodiment 1

[0046] 1. Preparation of ceramic slurry

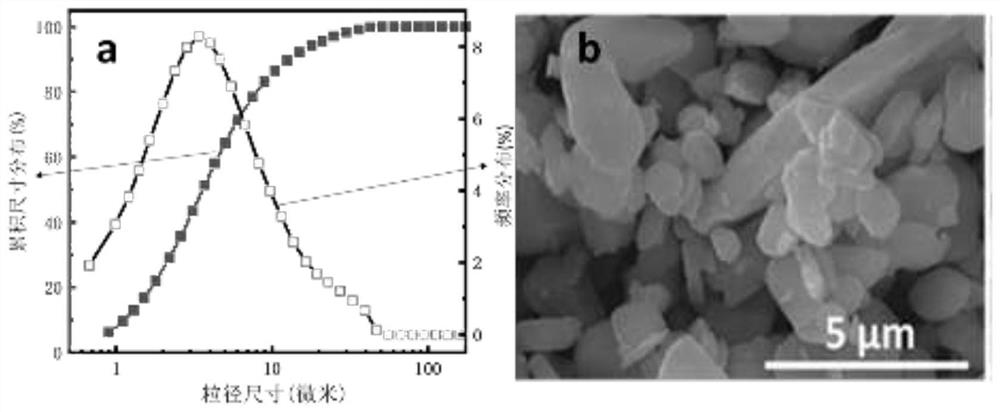

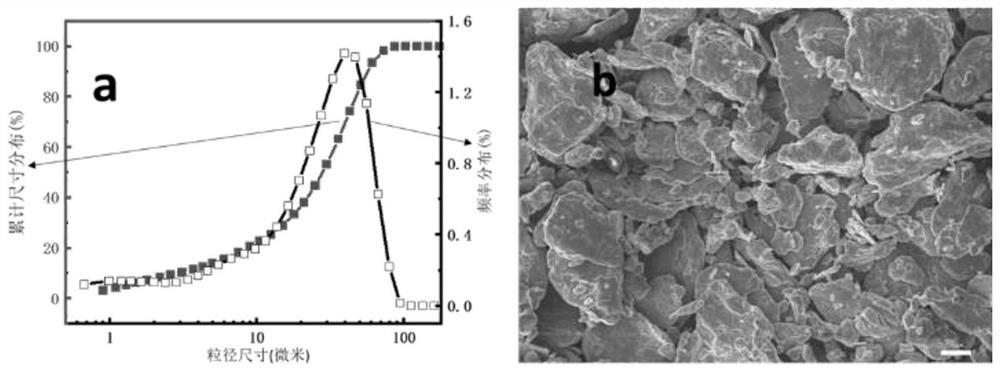

[0047] Ceramic powder: alumina (particle size and microscopic appearance such as figure 2 Shown in a and b), mass percent in the slurry system: 60, 65, 70, 75, 80, made into 5 parts of slurry with gradient concentration gradient;

[0048] Metal powder: metal chromium (particle size and microscopic appearance such as figure 2 Shown in a and b), the mass percentage in the slurry system: 40, 35, 30, 25, 20, made into 5 parts of slurry with gradient concentration gradient;

[0049] Dispersant: sodium hexametaphosphate, PEG 6000, the dosage is 2% of the ceramic metal powder in the system.

[0050] Binder: sodium alginate, PVP K30, the dosage is 3% of the ceramic metal powder in the system.

[0051] Solvent: deionized water, the dosage is 10% of the ceramic metal powder in the system.

[0052] After the above materials are mechanically pre-mixed and fully contacted, they are transferred to a ball mill for ball milling for 24 hours at a...

Embodiment 2

[0059] 1. Preparation of ceramic slurry

[0060] Ceramic powder: alumina, mass percentage in the slurry system: 60, 65, 70, 75, 80, 100 to make 6 parts of slurry with gradient concentration gradient;

[0061] Metal powder: metal nickel, the mass percentage in the slurry system: 100, 40, 35, 30, 25, 20, made into 6 parts of slurry with gradient concentration gradient;

[0062] Dispersant: oleic acid, sodium polymetaphosphate, the dosage is 2% of the ceramic metal powder in the system.

[0063] Adhesive: polydimethylsiloxanol, PVP K30, the dosage is 3% of the ceramic metal powder in the system.

[0064] Solvent: deionized water, the dosage is 10% of the ceramic metal powder in the system.

[0065] After the above materials are mechanically pre-mixed and fully contacted, they are transferred to a ball mill for ball milling for 24 hours at a speed of 330r / min, so that the components are evenly dispersed, so that the sum of the mass percentages is 100% gradient ceramic metal slur...

Embodiment 3

[0073] 1. Preparation of ceramic slurry

[0074] Ceramic powder: silicon carbide and alumina, the mass ratio of the two is 1:1, and the mass percentage in the slurry system: 60, 70, 80, made into 3 parts of slurry with gradient concentration gradient;

[0075] Metal powder: metal chromium and nickel, the mass ratio of the two is 1:1, the mass percentage in the slurry system: 40, 30, 20, made into 3 parts of slurry with gradient concentration gradient;

[0076] Dispersant: polyethyleneimine, the dosage is 2.5% of the ceramic metal powder in the system.

[0077] Adhesive: polyvinyl alcohol, the dosage is 4% of the ceramic metal powder in the system.

[0078] Solvent: absolute ethanol, the dosage is 12% of the ceramic metal powder in the system.

[0079] After the above materials are mechanically pre-mixed and fully contacted, they are transferred to a ball mill for ball milling for 24 hours at a speed of 330r / min, so that the components are evenly dispersed, so that the sum of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com