Vertical polarization wire grid production device

A polarized wire grid and production device technology, applied in the field of microwave radiometer and microwave remote sensing, can solve the problems of single control variable, long production cycle, expensive price, etc., and achieve the effects of simplifying the mechanical structure, improving production efficiency and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

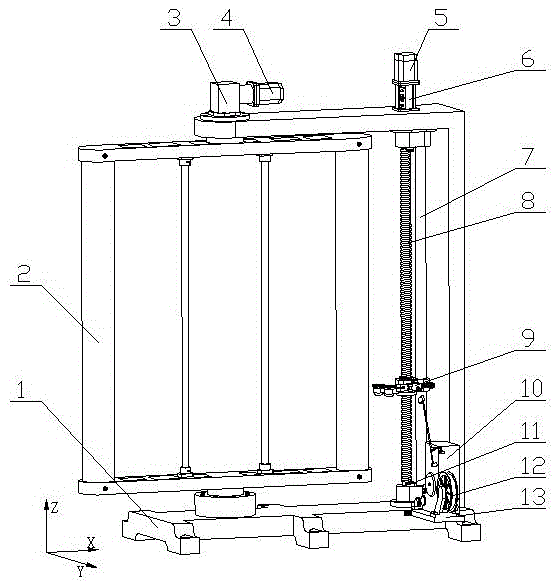

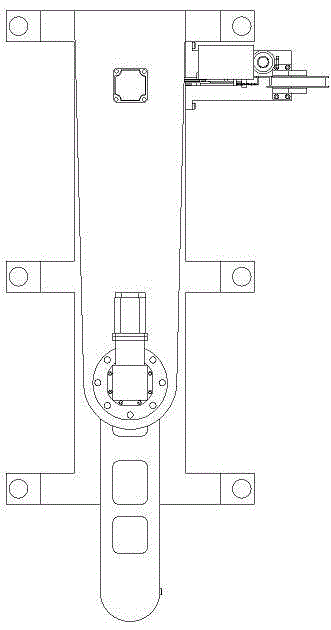

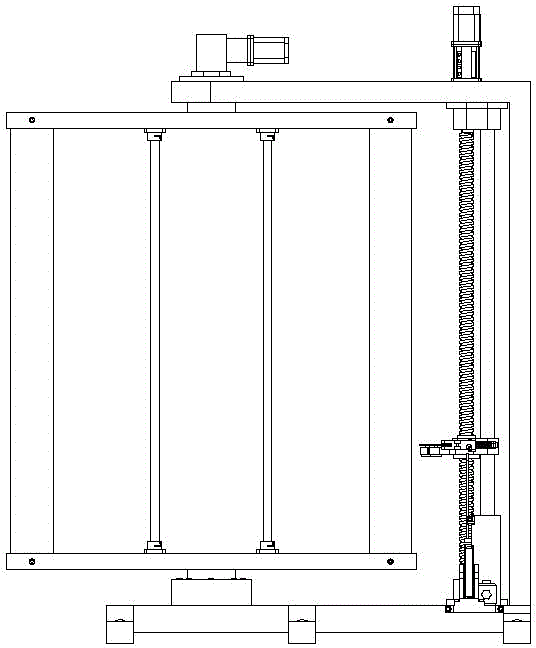

[0026] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0027] see Figure 1 to Figure 4 As shown, in the vertical polarized wire grid production device of the present invention, the polarized wire grid wire frame performs a rotary feed motion, and the wire release device, that is, the molybdenum wire guide and the tension buffer mechanism performs a linear feed motion. The structure includes a base, a rotary feed mechanism, a guide mechanism, a motor drive system, a limit protection mechanism, and a tension stabilization mechanism, wherein the base is composed of a base 1, a motor support 6, and a servo tensioner support 13. The base 1 is fixed on the plane by anchor bolts, and the motor support 6 and the servo tensioner support 13 are respectively fastened on the base 1 by screws;

[0028] The rotary feed mechanism is composed of a servo motor I4, a reducer 3, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com