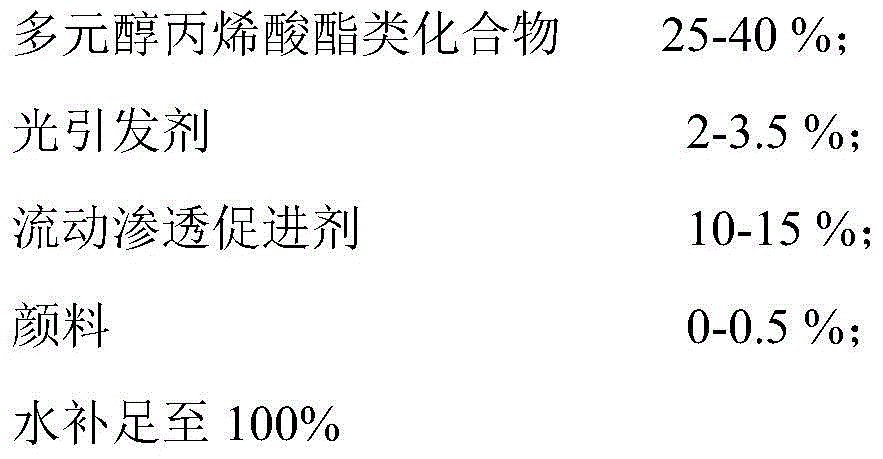

Polyol acrylate type photosensitive bonding agent for gypsous material 3D printing and preparation method thereof

A technology of alcohol acrylate and gypsum materials, which is applied in the field of 3D printing to achieve the effects of short setting time, reduced process complexity and high product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

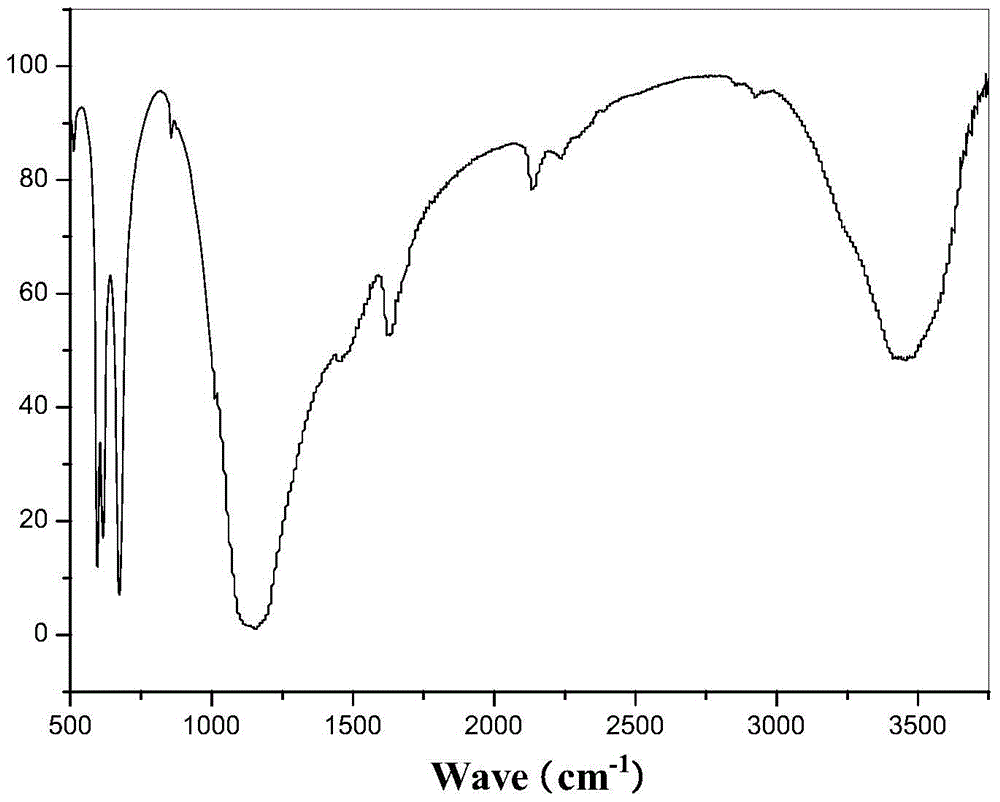

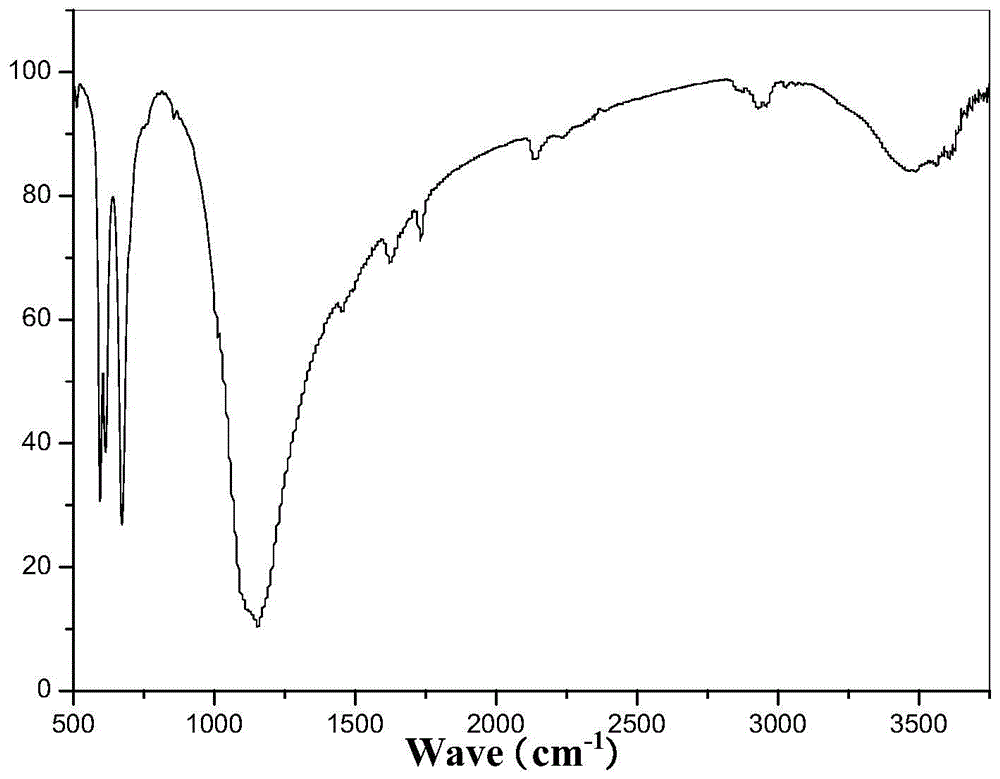

[0026] 30 g of polyethylene glycol dimethacrylate, 3 g of benzoin methyl ether, 12 g of isobutanol, 0.5 g of red pigment, and 54.5 g of deionized water. Before printing, mix the above raw materials evenly and place them in the printing nozzle, and print with 3dp technology. The curing light source is an ultraviolet light source. After printing, take out the product, put it in the above mixed solution for another 30 minutes, and then place it under the ultraviolet light source for irradiation. It can be cured for 8 hours. The formula has the advantages of fast binder penetration, short setting time, high product strength, environmental protection and no pollution. It is suitable for use as a binder for 3dp printing of plaster materials. figure 1 It is the infrared spectrogram of pure gypsum powder; figure 2 It is the infrared spectrogram of the binder solidified molded gypsum product obtained in Example 1. Compared figure 1 As can be seen, figure 2 Center at 2800cm -1 N...

Embodiment 2

[0028] 30 g of polyethylene glycol dimethacrylate, 3 g of benzoin methyl ether, 12 g of isobutanol, 0.5 g of red pigment, and 54.5 g of deionized water. Just mix the above raw materials evenly before printing. The printing method is the same as in embodiment 1.

Embodiment 3

[0030] Diethylene glycol diacrylate 25g, benzoin ethyl ether 3g, ethanol 10g, yellow pigment 0.5g, deionized water 61.5g. Just mix the above raw materials evenly before printing. The printing method is the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com