Preparation method of cellulose acetate nano filter-membrane

A cellulose acetate and nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of difficult to scrape the membrane, difficulty in stirring and dissolving evenly, high viscosity, etc. The effect of large amount and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a kind of preparation method of cellulose acetate nanofiltration membrane, carries out following steps successively:

[0026] 1), put 12g of cellulose acetate (CA) into 100ml of acetone (AC) and stir for 24 hours, then add 25ml of water (H 2 (2, for example, distilled water can be used) to stir for 2 hours, and finally leave it to stand for 72 hours to obtain the casting solution;

[0027] 2), at a temperature of 15°C and a relative humidity (air) of 60%, use a scraper to scrape the above-mentioned casting solution on a clean glass plate to form a wet film with a thickness of 250 μm; then make the wet film at the same temperature as above Under the condition of humidity and humidity, stand on the glass plate to volatilize the solvent, and the standing time is 1 minute;

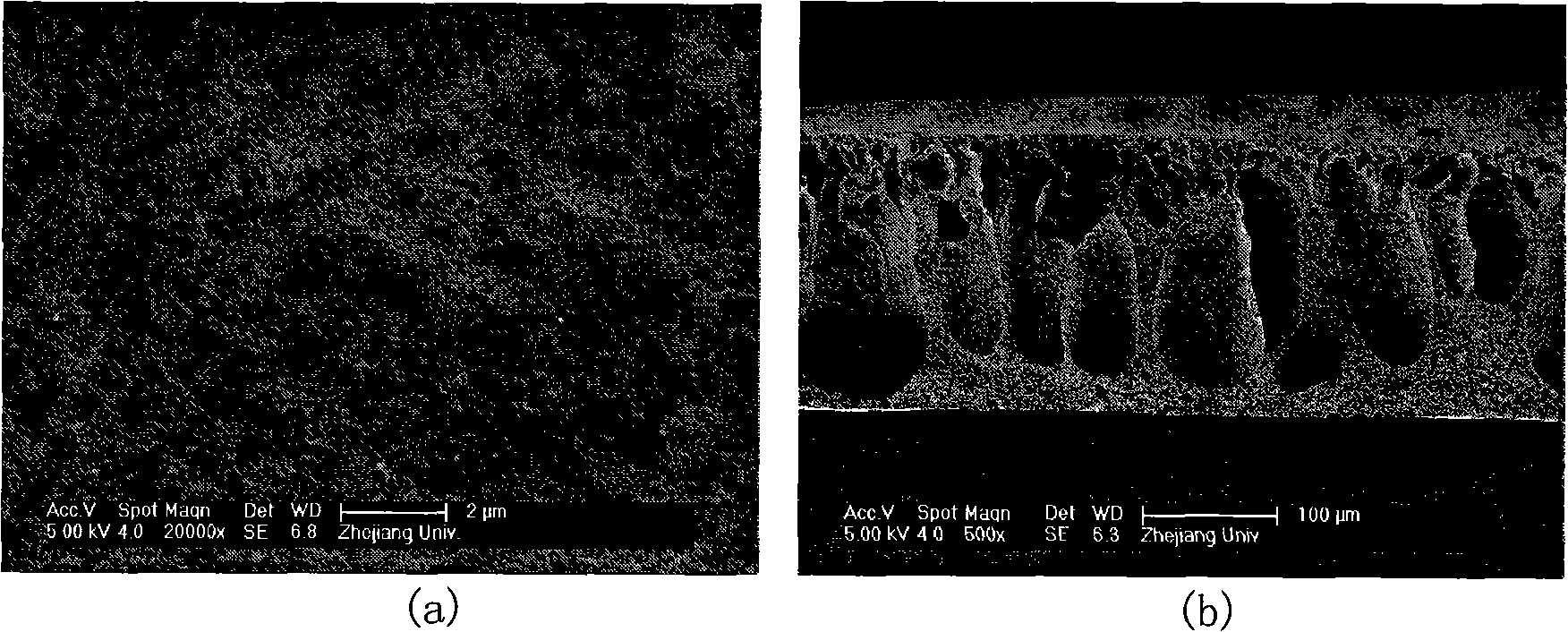

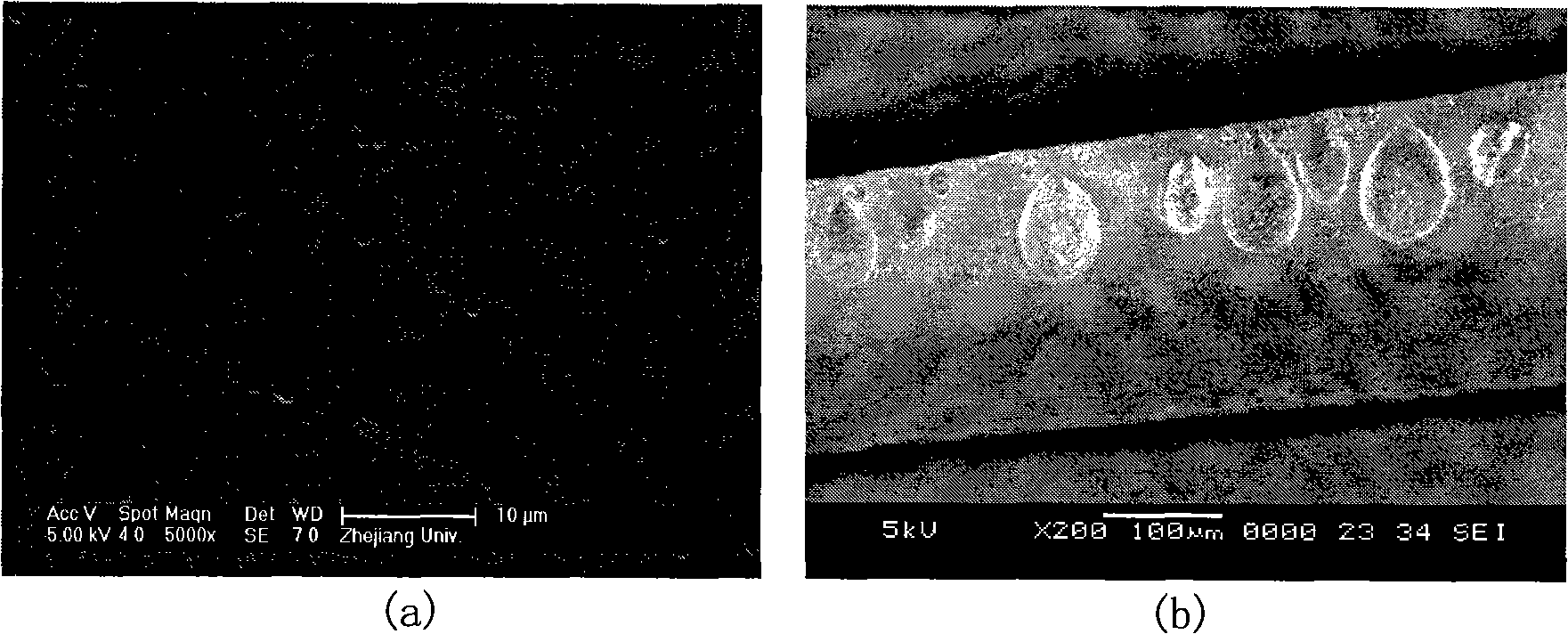

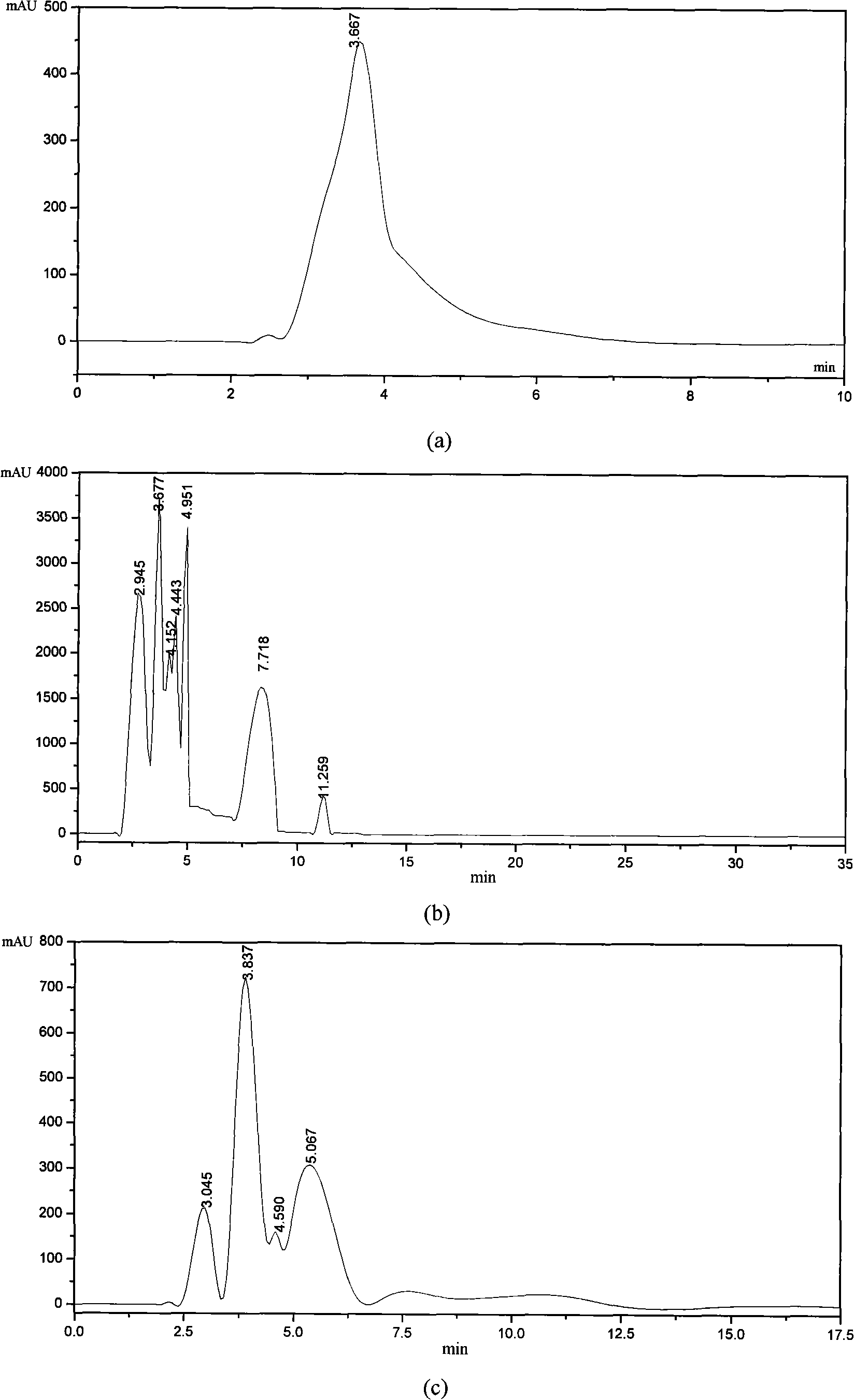

[0028] 3) The above volatilized wet film is immersed in 15°C distilled water for gel bath treatment until the wet film is fully gelled and solidified to form a film; an asymmetric film wi...

Embodiment 2

[0030] Embodiment 2, a kind of preparation method of cellulose acetate nanofiltration membrane, the temperature in step 2) is changed into 25 ℃, relative humidity is changed into 75%, and standing time is changed into 5 minutes; All the other are the same as embodiment 1 .

Embodiment 3

[0031] Embodiment 3, a kind of preparation method of cellulose acetate nanofiltration membrane, the consumption of the cellulose acetate in step 1) is changed into 15g; All the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com