Production method of preventing from coiling and pulling narrow of hot-rolled low carbon strip steels used for cold-rolled base plates

A low-carbon strip steel and manufacturing method technology, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problem of narrowing the width at the instant of coiling in hot continuous rolling, so as to reduce the amount of edge trimming and reduce the difficulty of control , The effect of improving production efficiency

Inactive Publication Date: 2010-12-15

NINGBO IRON & STEEL

View PDF6 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is to provide a manufacturing method for preventing the coiling and narrowing of hot-rolled low-carbon strip steel for cold-rolled substrates, so as to solve the problem of instantaneous width narrowing in hot continuous rolling coiling in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Login to View More

Abstract

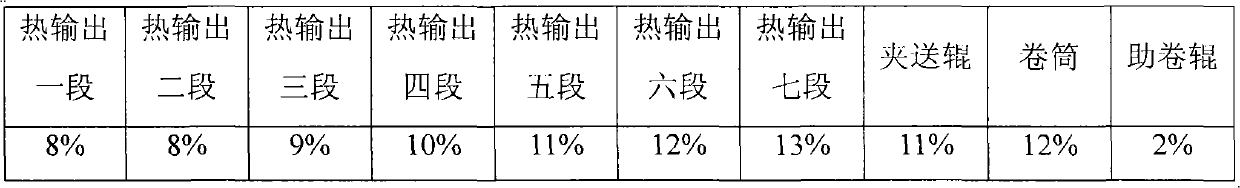

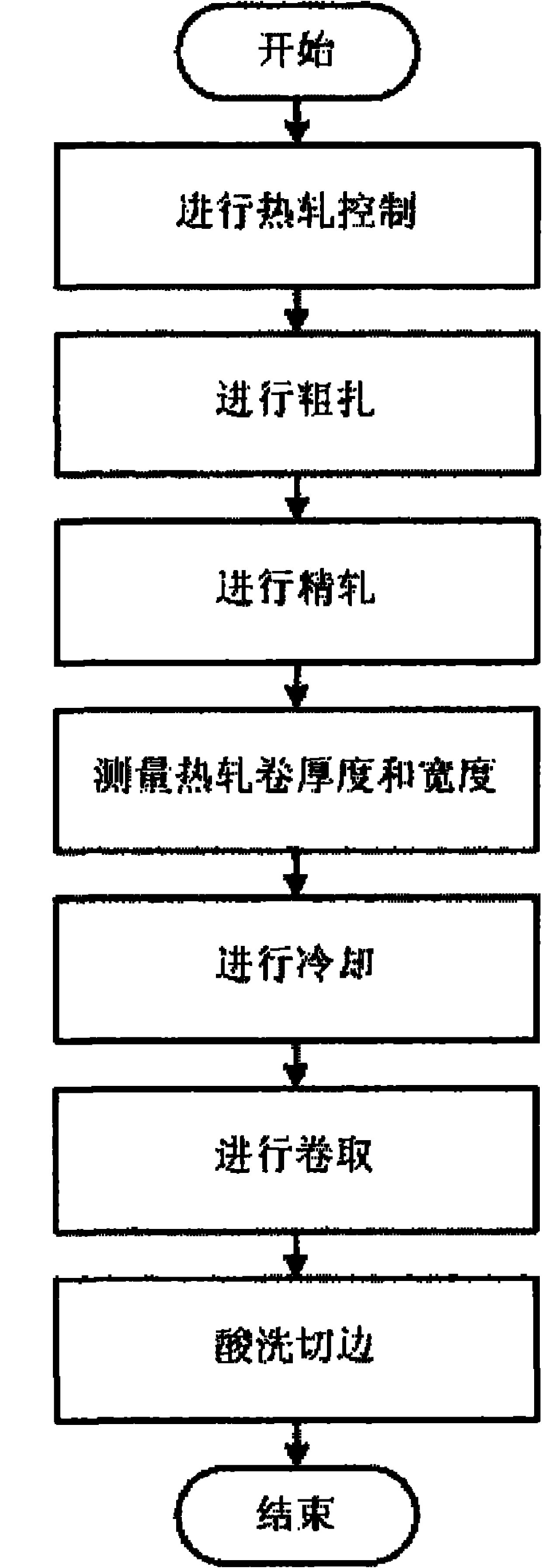

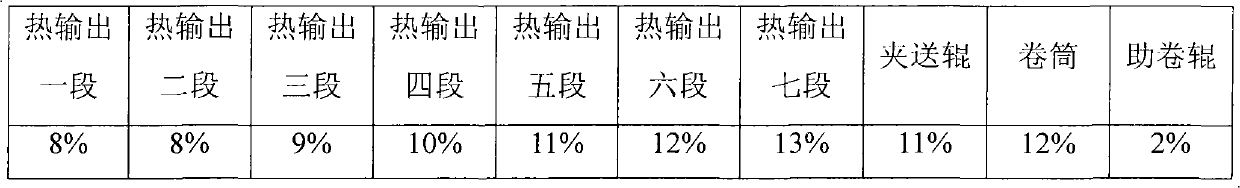

The invention discloses a production method of preventing from coiling and pulling narrow hot-rolled low carbon strip steels used for cold-rolled base plates, which comprises the following steps of: (1) controlling hot rolling, and heating plate blanks to 1190 to 1250 DEG C with temperature differences of the same plate equal or less than 40 DEG C; (2) carrying out rough rolling by adopting a 2-stage-3-point short stroke control with an outlet temperature of 1030 to 1080 DEG C; (3) carrying out finishing rolling at a temperature of 860 to 900 DEG C; (4) measuring thicknesses and widths of hot rolled steel coils; (5) carrying out laminar cooling; (6) setting each lead rate and coiling tension and coiling at a temperature of 560 to 670 DEG C; and (7) carrying out acid cleaning and cutting. The invention completely solves the problem of coiling and pulling narrow the hot-rolled low carbon strip steels used for the cold-rolled base plates by controlling hot rolling temperatures, short strokes of rough rolling, coiling lead rates, and coiling tensions.

Description

technical field The invention relates to the technical field of hot-rolled low-carbon steel strips for cold-rolled substrates, in particular to a manufacturing method for preventing coiling and narrowing of hot-rolled low-carbon steel strips for cold-rolled substrates. Background technique At present, the annual demand for low-carbon hot-rolled strip steel for cold-rolled base materials in China is very large, about 15 million tons, while the annual consumption in Jiangsu and Zhejiang regions alone reaches more than 3 million tons. During the production process of the hot tandem rolling unit, after the strip is finished rolling, it is cooled by laminar flow (hot output roller table), and after being pinched by the roller, it enters the coiler to be coiled into a steel coil, and then it is used for pickling in the cold rolling mill. Edge trimming and cold rolling production, hot rolling production specifications are generally between 1.8--4.5mm, and cold rolling specification...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21B1/22B21B37/74B21B37/16

Inventor 苗润涛张保忠吴伟娟

Owner NINGBO IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com