Novel 3D printed reinforced wall and construction method thereof

A 3D printing and wall technology, applied in the direction of walls, building types, building components, etc., can solve the problems of poor tensile performance, ductility and energy consumption performance, etc., to enhance the performance of bearing horizontal loads and enhance the overall Effects of performance, improved stability, and ability to withstand seismic horizontal action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

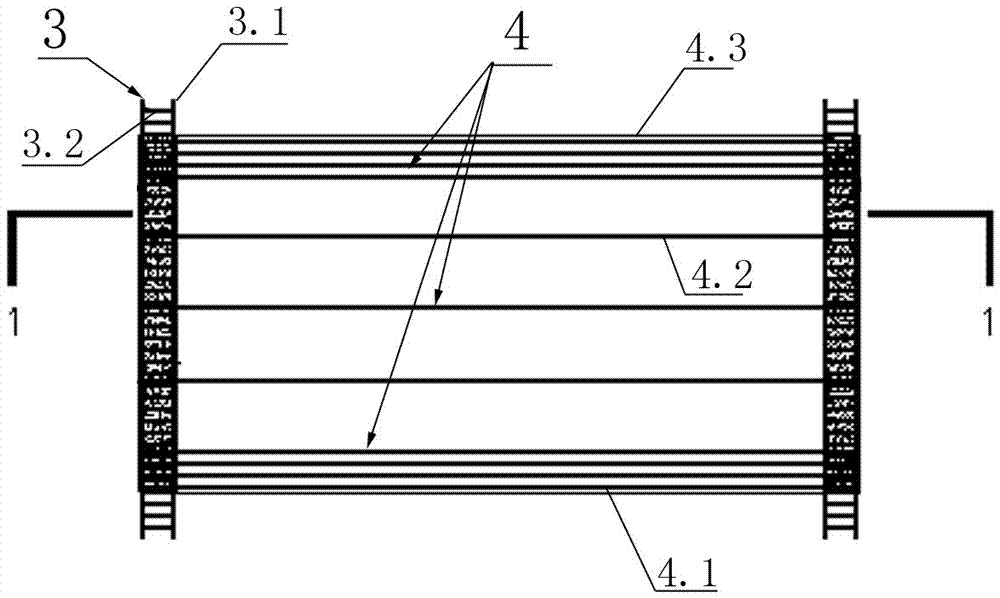

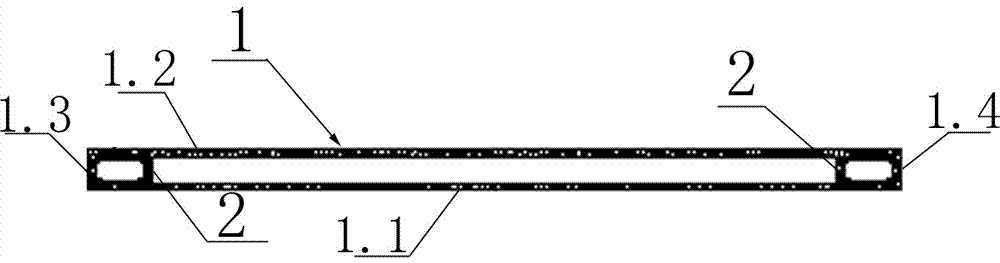

[0036] Such as figure 1 and figure 2 As shown, this new type of 3D printing reinforced wall includes a wall body that is integrally printed by a 3D printer; the wall body includes an external rectangular frame plate 1 and a partition frame plate along the width direction of the wall body 1, a vertical partition 2 forming a cavity; the frame panel 1 includes a front side panel 1.1, a rear side panel 1.2, a left side panel 1.3 and a right side panel 1.4; the vertical partition 2 has Two pieces, connected between the front side panel 1.1 and the rear side panel 1.2, close to the two ends of the frame panel 1, and the vertical partition panel 2 is connected to the front side panel 1.1, the rear side panel 1.2, the left side panel 1.3 or the right The side plate 1.4 encloses a rectangular cavity; the main body of the wall is provided with a structural column steel skeleton 3 and a transverse steel bar 4;

[0037] There are two structural column steel skeletons 3, which are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com