Expanding apparatus for heat exchange pipe

A heat exchanger, U-tube technology, applied in heat exchange equipment, tubular elements, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

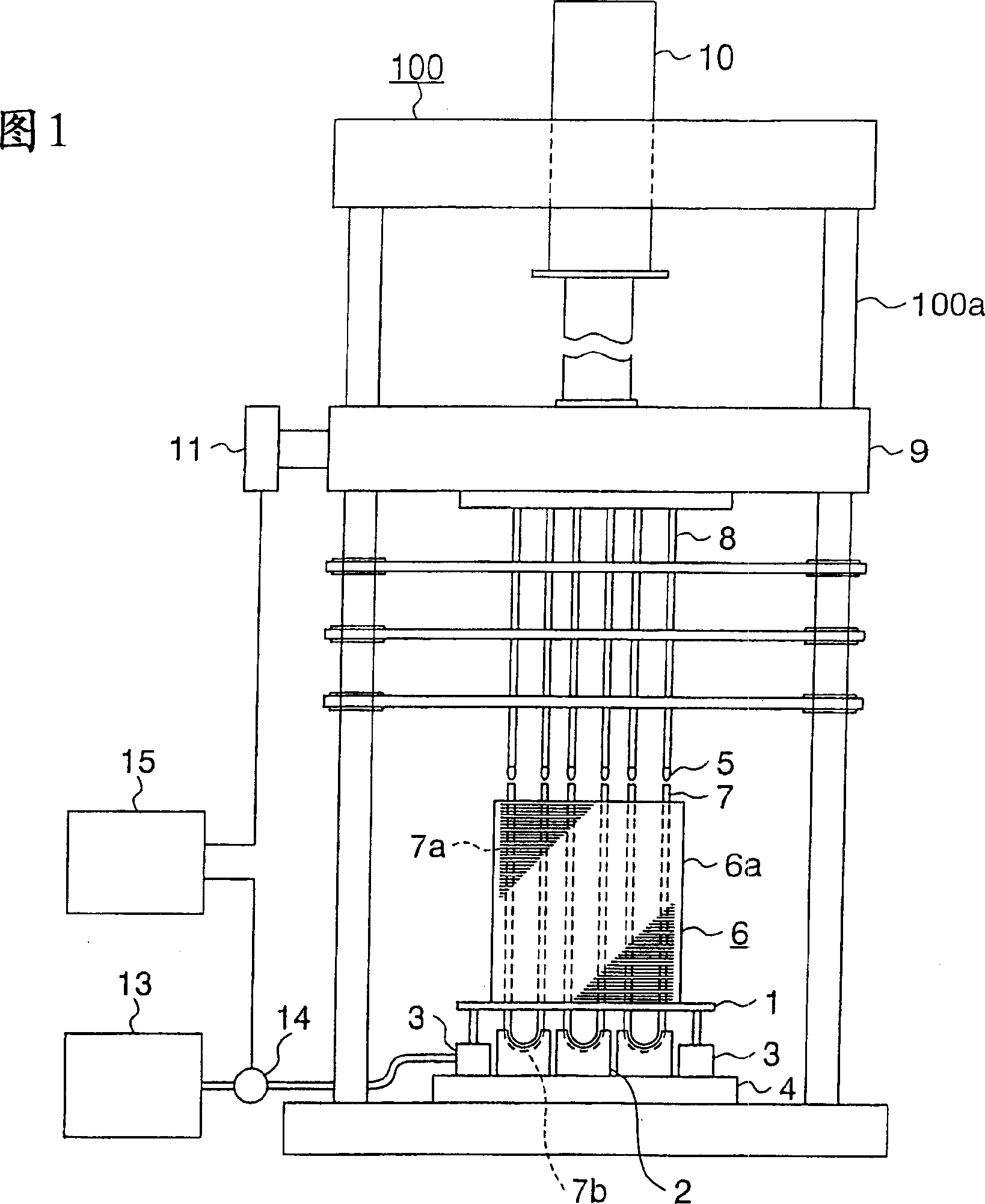

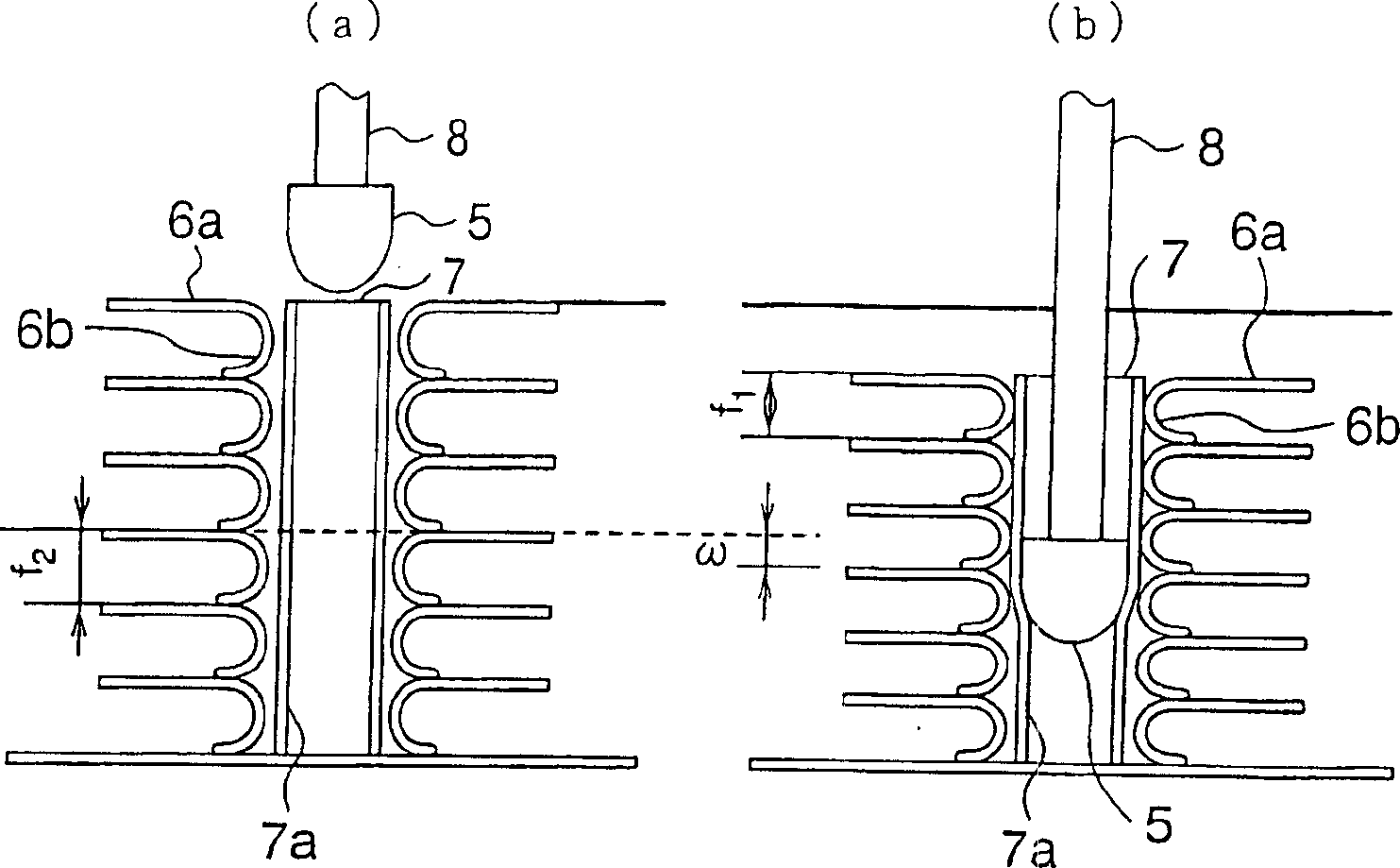

[0024] Fig. 1 is a front view showing the overall configuration of a pipe expanding device according to Embodiment 1 of the present invention. In FIG. 1 , a heat exchanger 6 is placed in a pipe expander 100 . The heat exchanger 6 is used, for example, as a fin-and-tube heat exchanger of an air conditioner or the like. The heat exchanger 6 is composed of a plurality of fins 6a stacked in the vertical direction in FIG. 1 and a plurality of U-shaped tubes 7 passing through the fins 6a in the stacking direction. The U-shaped pipe 7 is composed of two linear portions 7a bent in a substantially U-shape and extending in parallel, and a curved portion 7b connecting the ends thereof. A plurality of U-shaped tubes 7 are inserted through the stacked cooling fins 6a from one side, the straight portion 7a passes through the cooling fins 6a, and the curved portion 7b protrudes from the side end. A hole through which the U-shaped tube 7 passes is formed on the main surface of the heat sink...

Embodiment approach 2

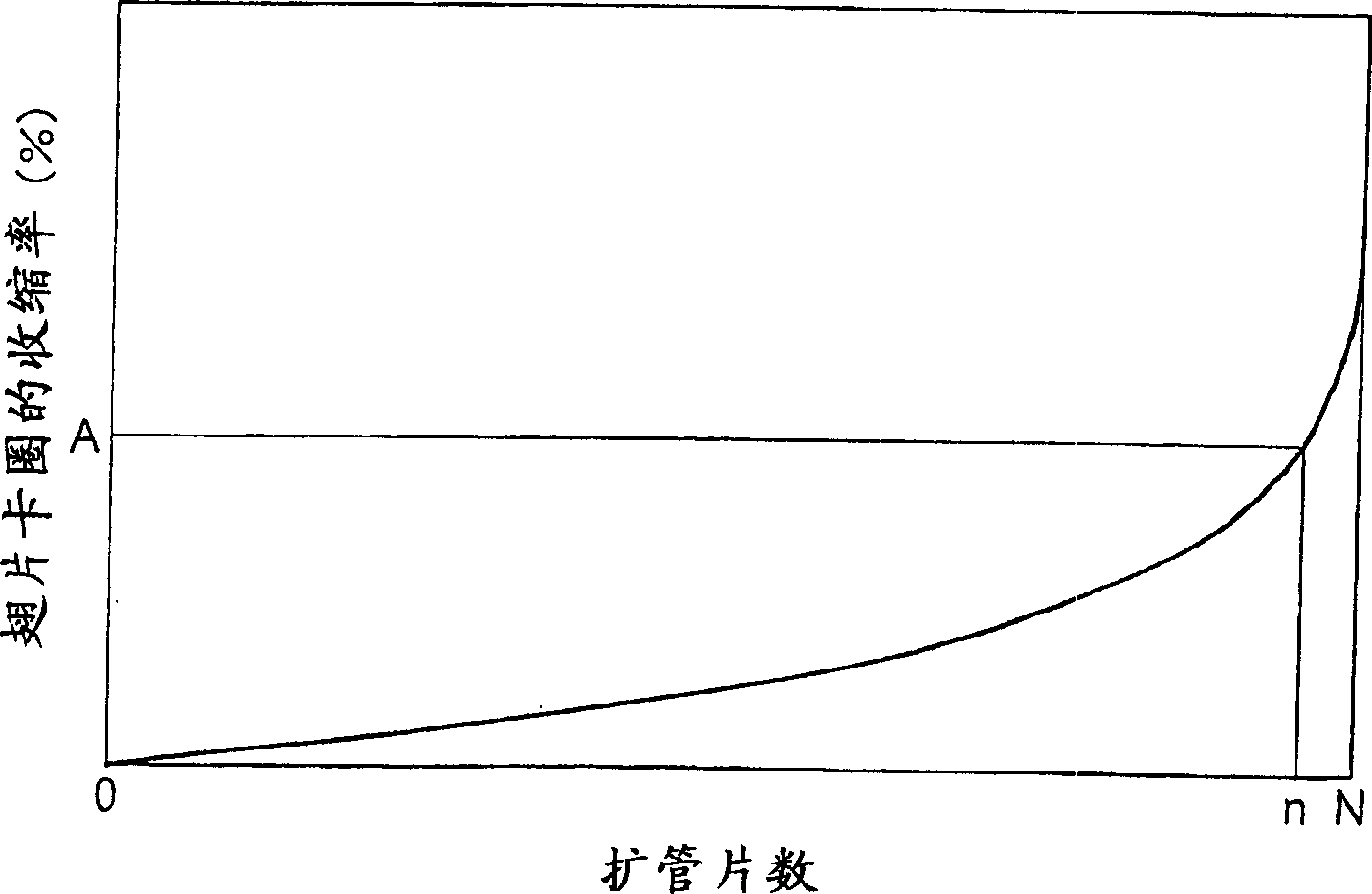

[0045] Figure 8 It is a relational figure which shows the point which lowers the fin receiver 1 which concerns on Embodiment 2 of this invention. The vertical axis represents the descending amount of the fin receiver 1, and the horizontal axis represents the number of fins 6a after tube expansion. The solid line in the figure represents the descending amount of the fin receiver 1 during the expansion process.

[0046] In this embodiment 2, as Figure 8 As shown, at a certain speed, it drops to point X in the initial stage of pipe expansion, and at a speed higher than the initial stage, it drops to point Y in the middle stage of pipe expansion. In this way, since the increase ratio of the cumulative shrinkage amount tends to increase in the later stage of pipe expansion compared with the initial stage, it decreases from point Y to point Z with a further increase in speed. The descending mode of the finned receiver 1 set in this way, the descending amount of the finned recei...

Embodiment approach 3

[0059] Figure 11 It is a front view showing the configuration of main parts of the pipe expanding device according to Embodiment 3 of the present invention. In this embodiment, both ends of the fin receiver 1 are supported by elastic bodies through which the guide posts 17 pass. As the elastic body, for example, a coil spring 18 set in compression is used. When the mandrel 8 is lowered, the billet 5 is inserted into the upper end of the U-shaped pipe 7, and pipe expansion starts. When the billet 5 further descends and reaches the fin 6a group, the compressive load applied to the fin collar 6b before pipe expansion starts to accumulate. Since the compressive load is transmitted from the fin receiver 1 to the coil spring 18 and is used to compress the coil spring 18 along the guide column 17, the compressive load accumulated on the fin collar 6 before tube expansion can be reduced. After pipe expansion is completed, if the mandrel 8 is raised to extract the billet 5 from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com