Filament spun-bonded antibacterial non-woven fabric framework material and a manufacturing method and application thereof

A skeleton material and manufacturing method technology, applied in rayon manufacturing, separation method, melt spinning method, etc., can solve the problems of poor discoloration resistance, poor fabric style aesthetics, small springback deformation, etc., and achieve beautiful cloth style , good visual effect, excellent effect of discoloration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

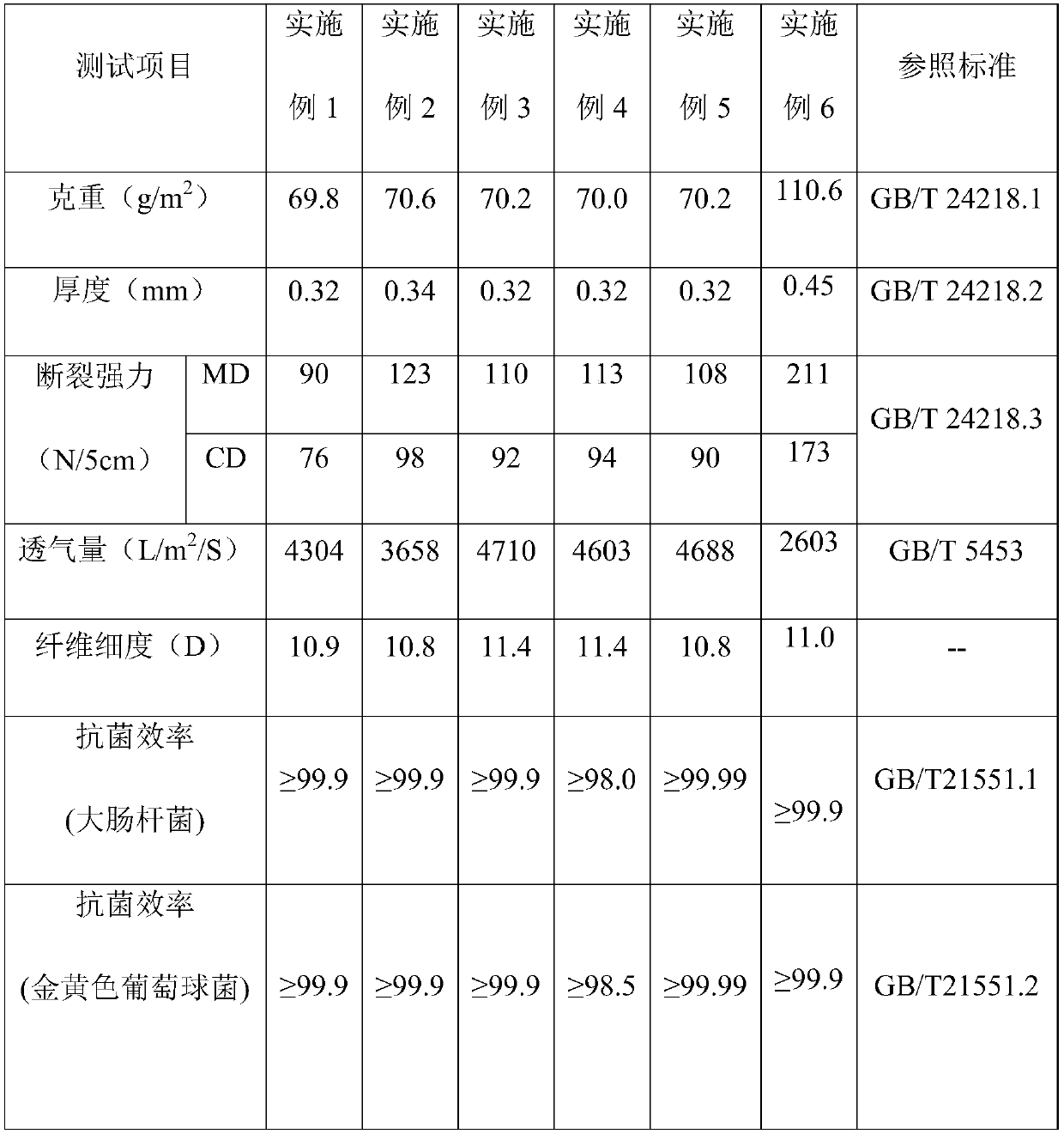

Examples

Embodiment 1

[0055] The production of the embodiment of the present invention mainly includes the following steps:

[0056] Component A is spinning grade PBT chips and antibacterial masterbatch mixture,

[0057] The melting point of PBT is 220-230°C,

[0058] The melting point of antibacterial masterbatch is 224℃~230℃;

[0059] Component B polymer is spinning grade PET chip, melting point 235~255℃.

[0060] Two-component skin-core ratio A:B=3:7

[0061] The above two polymers are polyester polymers. The former is directly melted and extruded through a twin-screw extruder that can dehumidify moisture without drying the material, while the latter needs to be treated at 155°C for 9 hours and then processed. Single-screw extruder for melt extrusion.

[0062] The mixture of component A is melted through a twin-screw extruder, and its temperature zone is set as: 220°C, 230°C, 240°C, 240°C, 240°C, 240°C, 240°C, 235°C, and the melt temperature is 236°C. The temperature of the twin-screw pipel...

Embodiment 2

[0066] The production of the embodiment of the present invention mainly includes the following steps:

[0067] Component A is spinning grade PBT chips and silver-based antibacterial masterbatch mixture,

[0068] The melting point of PBT is 220-230°C,

[0069] The melting point of antibacterial masterbatch is 224°C-230°C;

[0070] Component B polymer is spinning grade PET chip, melting point 235~255℃.

[0071] Two-component skin-core ratio A:B=5:5

[0072] The above two polymers are polyester polymers. The former is directly melted and extruded through a twin-screw extruder that can dehumidify moisture without drying, while the latter needs to be treated at 155°C for 8 hours and then processed. Single-screw extruder for melt extrusion.

[0073] The mixture of component A is melted through a twin-screw extruder, and its temperature zone is set as: 220°C, 230°C, 240°C, 240°C, 240°C, 240°C, 240°C, 235°C, and the melt temperature is 236°C. The temperature of the twin-screw pip...

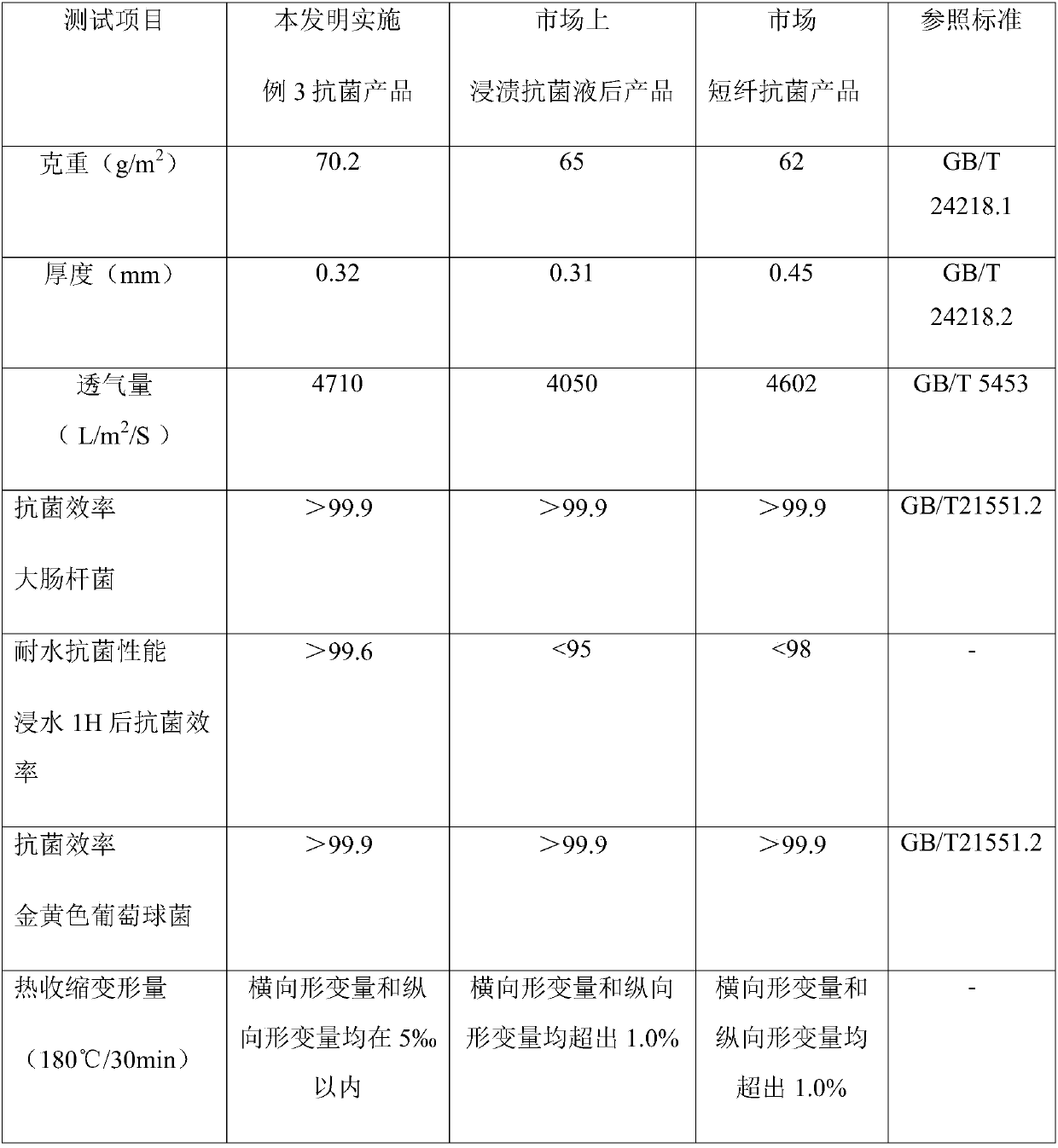

Embodiment 3

[0077] The production of the embodiment of the present invention mainly includes the following steps:

[0078] Component A is spinning grade PBT chips and silver-based antibacterial masterbatch mixture,

[0079] The melting point of PBT is 220-230°C,

[0080] The melting point of antibacterial masterbatch is 224°C-230°C;

[0081] Component B polymer is spinning grade PET chip, melting point 235~255℃.

[0082] Two-component skin-core ratio A:B=4:6

[0083] The above two polymers are polyester polymers. The former is directly melted and extruded through a twin-screw extruder that can dehumidify moisture without drying the material, while the latter needs to be treated at 155°C for 10 hours and then processed. Single-screw extruder for melt extrusion.

[0084] The mixture of component A is melted through a twin-screw extruder, and its temperature zone is set as: 220°C, 230°C, 240°C, 240°C, 240°C, 240°C, 240°C, 235°C, and the melt temperature is 236°C. The temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com