Metal or ceramic consumable item for FDM 3D printing, preparation method for metal or ceramic consumable item and finished product printing method

A technology of ceramics and metals, applied in the field of 3D printing, can solve the problems of expensive equipment processing costs, limited application of metals and ceramics, and limited printing structures, and achieve low material and processing costs, wide range of adaptable materials, and high miniaturization capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

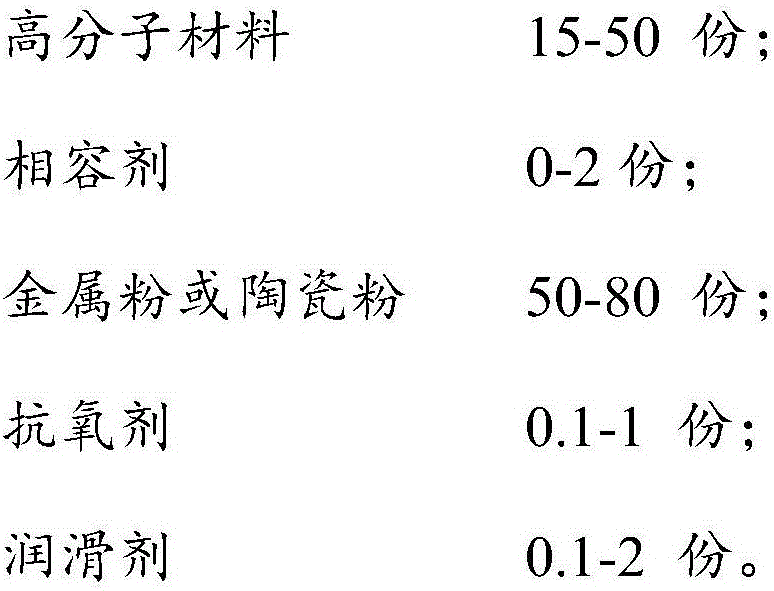

Method used

Image

Examples

Embodiment 1

[0032] Step S11: Weigh the raw materials of each component according to the component distribution ratio of metal consumables for FDM3D printing, PP3015: 1.0KG, POE610: 0.5KG, PP-g-MAH: 0.2KG, aluminum powder: 8KG, antioxidant 1010: 0.05 KG, antioxidant 168: 0.05KG, EBS: 0.1KG, calcium stearate: 0.1KG.

[0033] Step S12: Mix the materials evenly with a mixer.

[0034] Step S13: Extrude the mixed material through a twin-screw extruder at a processing temperature of 180-220° C., water-cool, air-dry, and pelletize to make PP-bonded aluminum pellets.

[0035] Step S14: The pellets are extruded through a single-screw extruder at a processing temperature of 200°C, water-cooled, air-dried, drawn into strips, and coiled to produce metal aluminum consumables for FDM3D printing.

[0036] Step S15: Print and shape the metal aluminum consumables for FDM3D printing with the FDM3D printer, and the printing temperature is 220°C.

[0037] Step S16: The obtained printed part is subjected to ...

Embodiment 2

[0039] Step S21: Weigh the raw materials of each component according to the component distribution ratio of metal consumables for FDM3D printing, ABS757: 4.0KG, ABS high rubber powder: 1.0KG, maraging steel powder: 5.0KG, antioxidant DLTP: 0.005KG , antioxidant 168: 0.005KG, paraffin: 0.01KG.

[0040] Step S22: mix each component uniformly by a mixer.

[0041] Step S23: Extrude the mixed material through a twin-screw extruder at a processing temperature of 200° C., water-cool, air-dry, and pelletize to make ABS-bonded metal steel pellets.

[0042] Step S24: Extrude the pellets through a single-screw extruder at a processing temperature of 210°C, water-cool, air-dry, draw a strip, and coil to make a metallic steel consumable for FDM3D printing.

[0043] Step S25: The metal steel consumables for FDM3D printing are printed and shaped by the FDM3D printer, and the printing temperature is 220°C.

[0044] Step S26: Solvent degrease the obtained printed part in DBE solution at 60°C f...

Embodiment 3

[0046] Step S31: Weigh the raw materials of each component according to the composition ratio of metal consumables for FDM3D printing, PVA: 3.0KG, titanate coupling agent: 0.05KG, titanium alloy powder: 7.0KG, antioxidant 1010: 0.01KG, Antioxidant 168: 0.02KG, OP wax: 0.05KG.

[0047] Step S32: first mix the titanium alloy powder and the titanate coupling agent uniformly through a mixer, and then add the rest of the materials and mix uniformly.

[0048] Step S33: Extrude the mixed material through a twin-screw extruder at a processing temperature of 230-240° C., air-cool, air-dry, and pelletize to produce PVA-bonded titanium alloy pellets.

[0049] Step S34: Extrude the pellets through a single-screw extruder at a processing temperature of 230° C., air-cool, air-dry, draw a strip, and coil to make a metal titanium alloy consumable for FDM 3D printing.

[0050] Step S35: The titanium alloy consumables for FDM3D printing are printed into shape by the FDM3D printer, and the prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com