Resin composition for filling unit plate type ballastless track convex baffling platform

A technology of resin composition and mixture, applied in the directions of track, track maintenance, laying track, etc., can solve the problems of insufficient toughness, poor water resistance and aging resistance, and poor low temperature resistance, and achieves improved water resistance and aging resistance. The effect of improving water resistance and aging resistance, reasonable stiffness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

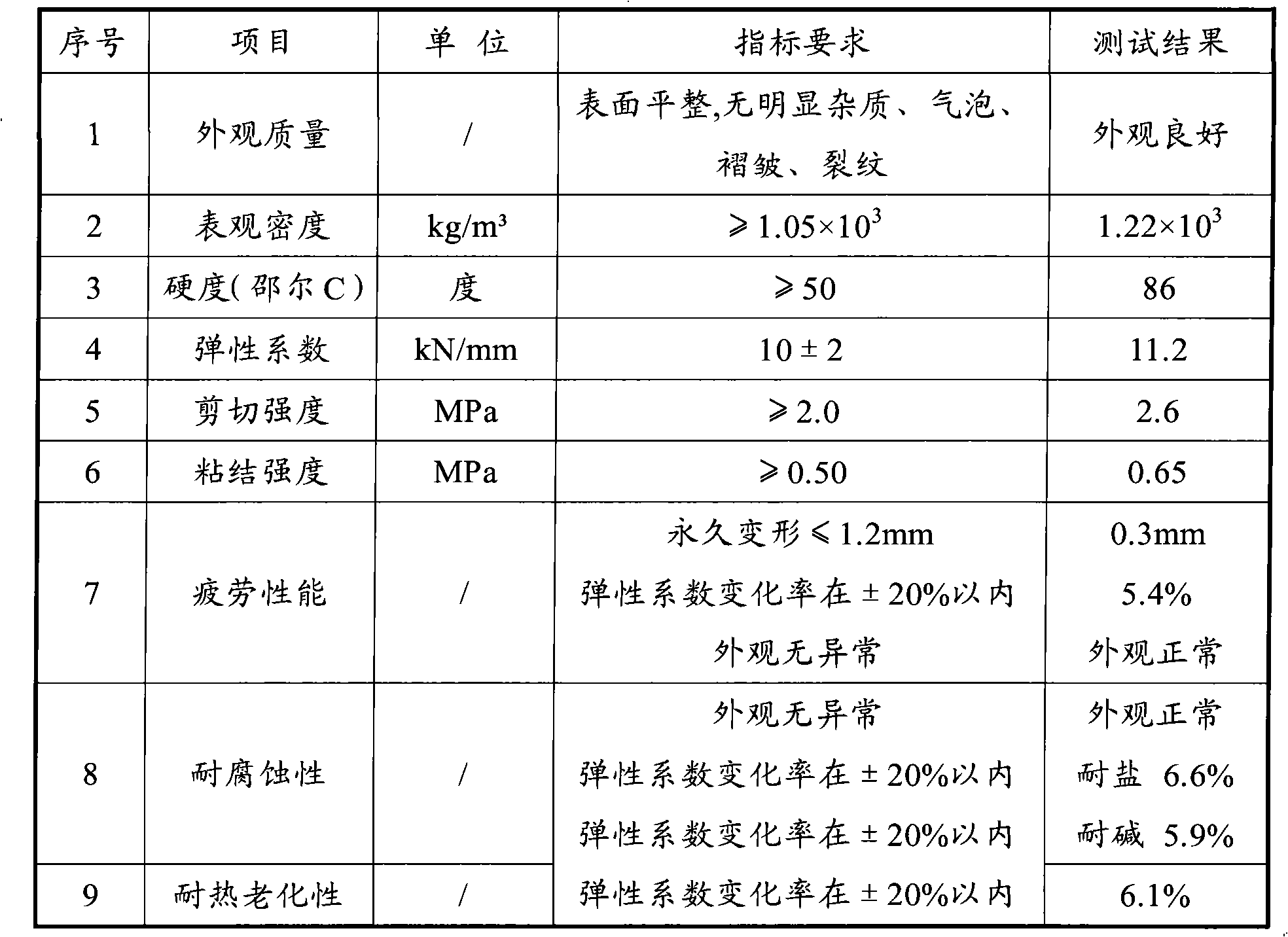

[0052] Embodiment 1 (applied to Wuhan-Guangzhou Passenger Dedicated Line)

[0053] Production: (consumption is calculated in parts by weight)

[0054] Component A: 100 parts of hydroxyl-terminated polybutadiene (hydroxyl value 1.03mmolKOH), 3 parts of chain extender 1,4-butanediol (Shanghai Gaoqiao Petrochemical), 30 parts of dibutyl phthalate, 40 parts of clay 0.2 parts of antifoaming agent BYK-066N (produced by BYK Company in Germany), 1 part of antioxidant 1010, 1 part of ultraviolet absorber UV-327, 1 part of white carbon black, 0.01 part of catalyst dibutyltin dilaurate, using three Grinding with a roller mill, using an anchor stirring device in the reactor, the rotation speed is 80 rpm, the temperature is 90°C, the vacuum degree is -0.09MPa, and the heating and vacuuming time is 6 hours. Cool to 60°C, pack and store.

[0055] Component B: 15 parts of PM-200 (manufactured by Yantai Wanhua), in airtight packaging.

[0056] Construction: first clean up the sundries betwe...

Embodiment 2

[0062] Embodiment 2 (applied to Wuhan-Guangzhou Passenger Dedicated Line)

[0063] Production: (consumption is calculated in parts by weight)

[0064] Component A: polymer diol POP05 / 45 (vinyl copolymer graft modified polyether diol, Tianjin Sanpei Chemical, hydroxyl value 20.5mgKOH) 100 parts, chain extender 1,4-butanediol 6 parts, 30 parts of dibutyl phthalate, 45 parts of silicon micropowder, 0.2 parts of defoamer BYK-066N (produced by German BYK company), 1 part of antioxidant 1010, 1 part of ultraviolet absorber UV-327, white 1 part of carbon black, 0.01 part of catalyst dibutyltin dilaurate, use colloid mill to disperse the filler, use anchor stirring equipment in the reactor, rotate at 100 rpm, temperature 110°C, vacuum degree -0.09MPa, heating and vacuuming time 4 Hour. Cool to 60°C, pack and store.

[0065] Component B: 12 parts of PM-200 (manufactured by Yantai Wanhua), in airtight packaging.

[0066] Construction: first clean up the sundries between the track ...

Embodiment 3

[0073] Embodiment 3 (applied to the test section of Harbin-Suifenhe line)

[0074] Production: (consumption is calculated in parts by weight)

[0075] Component A: 100 parts of hydroxyl-terminated polybutadiene (hydroxyl value 0.73mmolKOH), 5 parts of chain extender ethylene glycol, 30 parts of dioctyl sebacate, 45 parts of silicon micropowder, defoamer BYK-066N (Germany Produced by BYK company) 0.2 part, 1 part of antioxidant 1010, 1 part of white carbon black, 1 part of ultraviolet absorber UV-3271, adopt colloid mill to disperse filler, adopt anchor type stirring equipment in the reactor, rotating speed 100 rev / mins, temperature 110°C, vacuum degree -0.09Mpa, heating and vacuuming time for 4 hours. Cool to 60°C, pack and store.

[0076] Component B: 16 parts of PM-200 (manufactured by Yantai Wanhua), in airtight packaging.

[0077] Component C: 0.01-0.05 parts of dibutyltin dilaurate is used as the catalyst.

[0078]Construction: first clean up the sundries between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com